Optimizing Round Rasp Use in Drill Manufacturing Processes for Enhanced Efficiency

Round Rasp A Versatile Tool for Drill Factories

In the realm of manufacturing, particularly in drill factories, precision is paramount. Among the multitude of tools utilized to ensure exactness in production, the round rasp stands out for its versatility and efficiency. This handheld tool, typically made of hardened steel with a series of coarse, sharp teeth, is essential for shaping, smoothing, and finishing processes. Understanding the significance and applications of round rasps can illuminate how they contribute to the production of high-quality drilling equipment.

The Structure and Design of Round Rasps

A round rasp features a cylindrical shape, characterized by its distinctive pattern of raised teeth. The design allows for the tool to efficiently remove material from various surfaces, reaching into rounded spaces and intricate contours that flat rasps or files might struggle with. The handle of most round rasps is ergonomically designed, providing users with a comfortable grip. This design is crucial in drill factories where operators may be using these tools extensively throughout the day.

The coarse texture of a round rasp makes it particularly effective for rapid material removal. As manufacturers often work with a variety of materials, including metals, wood, and composites, the adaptability of the round rasp becomes an invaluable asset. High-quality rasps are made from durable materials that can withstand the wear and tear of continuous use while maintaining their effectiveness in performance.

Applications in Drill Factories

In drill factories, the round rasp plays a critical role in several processes, such as deburring, shaping, and finishing. When drilling equipment is produced, it often requires the removal of sharp edges and burrs that can result from other machining processes. A round rasp is vital in this deburring stage, ensuring that products are safe to use and free from defects that could affect their performance.

round rasp for drill factories

Shaping is another important application. When components of drilling equipment need to fit precisely into one another, any excess material must be removed to achieve the desired profile. Round rasps excel in creating smooth transitions and tight tolerances in round or cylindrical parts, such as drill bits and shafts. Their ability to reach into narrow spaces is especially beneficial in optimizing the overall design and functionality of the equipment.

Finishing touches are equally crucial in ensuring that the products meet the required standards of quality. A smooth finish enhances not only the aesthetic appeal of the final product but also its performance characteristics. Round rasps allow for fine-tuning and polishing of surfaces, creating a final product that operates seamlessly in various applications.

Advantages of Using Round Rasps

One of the primary advantages of using a round rasp in drill factories is its efficiency. The ability to rapidly shape and smooth materials means that production timelines can be significantly shortened without sacrificing quality. Furthermore, round rasps can be used in manual or power tool applications, making them adaptable to different working styles and environments.

Another benefit is their cost-effectiveness. Compared to more complex machinery or powered tools, round rasps are relatively inexpensive. This affordability makes them accessible not only for larger factories but also for smaller workshops, promoting versatility in equipment and tool selection.

Conclusion

In conclusion, the round rasp is an indispensable tool in the arsenal of drill factories, contributing significantly to efficiency, precision, and quality in manufacturing processes. Its design allows for the effective removal of material and the careful shaping of components, ensuring that finished products not only meet industry standards but also strive for excellence. As technology continues to evolve in manufacturing, the fundamental necessity of tools like the round rasp remains, proving that even the simplest designs can have a profound impact on productivity and quality in drill production. Understanding and employing the round rasp effectively can equip manufacturers with the means to enhance their operational capabilities, further pushing the boundaries of what's possible in drill manufacturing.

Share

-

Uses of Jute Bags | Sustainable Jute ProductsNewsAug.12,2025

-

Types of Square Files and Their Uses in Modern IndustriesNewsAug.12,2025

-

Slitting Machines Overview & TypesNewsAug.12,2025

-

Jute Rope: The Versatile Material for DIY & CraftingNewsAug.12,2025

-

How to Use Tofu Cat Litter for the Best ResultsNewsAug.12,2025

-

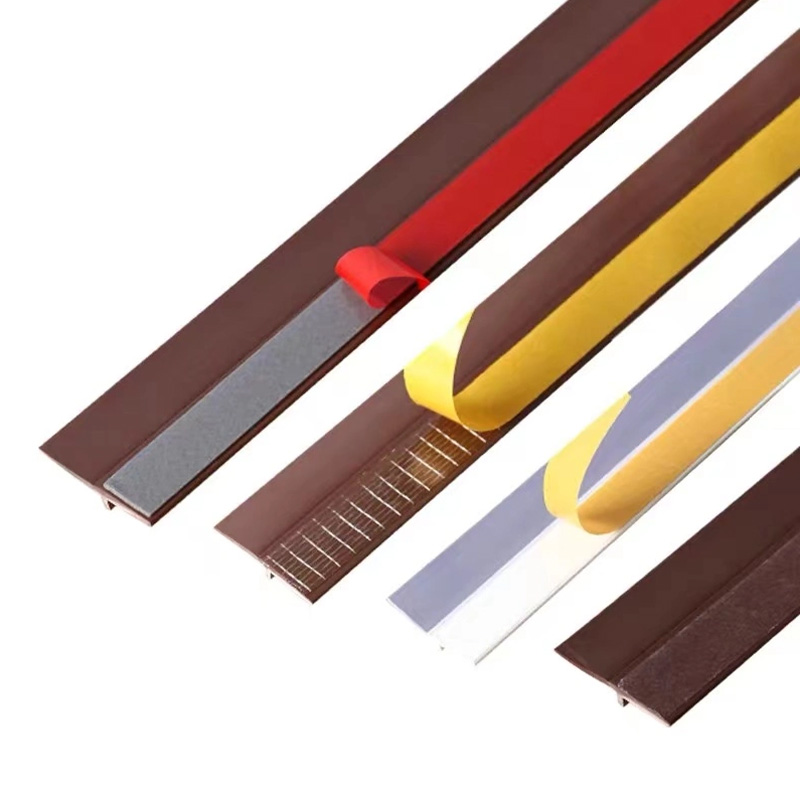

Car Door Seal Buying GuideNewsAug.12,2025