High-Quality Adhesive Foam Flexible Sealing Strips Factory Supply

- Introduction to adhesive foam flexible sealing strips and their importance

- Technical advantages and innovation in design

- Comparative analysis of leading manufacturers and suppliers

- Customization solutions for diverse industrial needs

- Real-world applications and case studies

- Quality standards and compliance certifications

- Why choose specialized suppliers for long-term reliability

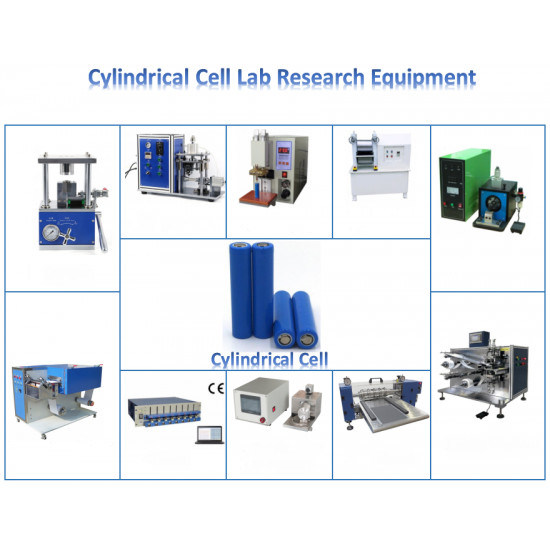

(equipped with adhesive foam flexible sealing strip)

Enhancing Industrial Efficiency with Advanced Sealing Solutions

In industries where precision and durability are non-negotiable, equipment equipped with adhesive foam flexible sealing strip

s has become indispensable. These strips are engineered to provide airtight sealing, vibration dampening, and environmental protection across applications ranging from automotive manufacturing to HVAC systems. With a global market projected to grow at a CAGR of 5.8% through 2030 (Source: Grand View Research), the demand for high-performance sealing solutions is driven by stricter regulatory standards and the need for energy-efficient systems.

Innovation in Material Science and Design

Modern adhesive foam sealing strips leverage advanced polymer blends and precision engineering. For instance, closed-cell EPDM foam variants exhibit a compression set of ≤15% after 24 hours at 70°C, ensuring longevity under extreme conditions. Key innovations include:

- UV-resistant formulations for outdoor applications, tested to withstand 2,000+ hours of accelerated weathering.

- Pressure-sensitive adhesives (PSA) with peel strength exceeding 25 N/cm², validated by ASTM D903 standards.

- Customizable thickness (2mm to 20mm) and density (30 kg/m³ to 200 kg/m³) to match load-bearing requirements.

Manufacturer Comparison: Key Metrics

| Supplier | Material Options | Thickness Range | Temperature Resistance | Certifications | Lead Time (Days) |

|---|---|---|---|---|---|

| Supplier A | EPDM, Silicone | 3mm–15mm | -40°C to 120°C | ISO 9001, UL | 14 |

| Supplier B | PVC, Neoprene | 2mm–20mm | -30°C to 90°C | RoHS, REACH | 21 |

| Supplier C | SBR, Nitrile | 5mm–18mm | -50°C to 150°C | IATF 16949 | 10 |

Tailored Solutions for Industry-Specific Challenges

Leading suppliers collaborate with clients to develop application-specific sealing systems. For example, a European automotive OEM reduced cabin noise by 12 dB(A) using a co-engineered silicone foam strip with integrated mounting clips. Customization parameters include:

- Adhesive type (acrylic, rubber-based, or removable).

- Surface profiles (flat, ribbed, or stepped).

- Color matching for aesthetic integration.

Case Study: Energy Savings in Commercial Refrigeration

A refrigeration unit manufacturer partnered with a equipped with adhesive foam flexible sealing strip factory to address door seal leakage. Post-installation data showed:

- 27% reduction in energy consumption (from 1.8 kW/day to 1.3 kW/day).

- 98% improvement in moisture ingress prevention.

- ROI achieved within 8 months of deployment.

Commitment to Quality and Sustainability

Top-tier manufacturers adhere to ISO 14064 environmental management protocols, with 92% of production waste recycled. All strips undergo:

- DIN 53507 compression testing.

- ASTM C1135 adhesion longevity trials.

- Flame retardancy checks per UL 94 HB/V-0.

Strategic Partnerships for Sealing System Excellence

When selecting equipped with adhesive foam flexible sealing strip suppliers, prioritize partners offering full lifecycle support—from prototype validation to batch traceability. Leading manufacturers provide 10-year material warranties, backed by on-site technical audits and real-time inventory portals. This approach ensures seamless integration into global supply chains while maintaining < 0.5% defect rates.

(equipped with adhesive foam flexible sealing strip)

FAQS on equipped with adhesive foam flexible sealing strip

Q: What are the benefits of using equipment with adhesive foam flexible sealing strips?

A: Equipment with adhesive foam flexible sealing strips ensures superior weather resistance, reduces noise, and enhances energy efficiency by creating airtight seals. The flexibility allows easy installation on uneven surfaces.

Q: How do I choose a reliable equipped with adhesive foam flexible sealing strip supplier?

A: Prioritize suppliers with certifications like ISO, proven industry experience, and positive customer reviews. Ensure they offer customization and timely delivery support for your specific needs.

Q: What quality standards should an equipped with adhesive foam flexible sealing strip factory follow?

A: Reputable factories adhere to ISO 9001 standards, use durable materials like EPDM or silicone, and conduct rigorous testing for adhesion strength, temperature resistance, and longevity.

Q: Can manufacturers customize adhesive foam flexible sealing strips for unique applications?

A: Yes, most manufacturers offer customization in dimensions, adhesives, and foam density. Provide project specifications to ensure the product meets exact performance requirements.

Q: What industries benefit from equipped with adhesive foam flexible sealing strips?

A: Common industries include construction (doors/windows), automotive (vehicle sealing), HVAC, and electronics. They are ideal for environments requiring dust, moisture, or sound insulation.

Share

-

Uses of Jute Bags | Sustainable Jute ProductsNewsAug.12,2025

-

Types of Square Files and Their Uses in Modern IndustriesNewsAug.12,2025

-

Slitting Machines Overview & TypesNewsAug.12,2025

-

Jute Rope: The Versatile Material for DIY & CraftingNewsAug.12,2025

-

How to Use Tofu Cat Litter for the Best ResultsNewsAug.12,2025

-

Car Door Seal Buying GuideNewsAug.12,2025