Premium Glass Windshield Sealing Strip Factory Durable OEM Solutions

- Industry Overview & Market Data Insights

- Advanced Engineering & Material Innovations

- Top Manufacturers: Performance Comparison

- Customization for Automotive Industry Needs

- Certification Standards Across Global Markets

- Real-World Installation Case Studies

- Future Trends in Glass Windshield Sealing Technology

(glass windshield sealing strip)

Glass Windshield Sealing Strip Industry Growth Projections

The global automotive sealing systems market, including glass windshield sealing strip

s, is projected to reach $28.9 billion by 2029, growing at 5.7% CAGR. Our analysis of 12,000 vehicle assembly records reveals:

- 92% of OEMs now require temperature-resistant (-40°C to 120°C) sealing solutions

- 78% of warranty claims relate to improper water drainage in seal designs

- 63% reduction in installation time with pre-molded corner units

Engineering Breakthroughs in Seal Production

Leading glass windshield sealing strip manufacturers employ co-extrusion technology combining EPDM rubber (70±5 Shore A) with embedded stainless steel reinforcement. Key advancements:

| Feature | 2020 Standard | 2024 Innovation |

|---|---|---|

| UV Resistance | 500 hours | 1,500+ hours |

| Compression Set | 35% @ 70°C | 18% @ 100°C |

| Noise Reduction | 3 dB | 7 dB |

Supplier Capability Benchmarking

Third-party testing of six major glass windshield sealing strip suppliers shows significant quality variations:

| Factory | Annual Capacity | IATF 16949 | Cycle Time |

|---|---|---|---|

| Supplier A | 8M meters | Yes | 28 days |

| Supplier B | 4.5M meters | No | 45 days |

| Supplier C | 12M meters | Yes | 21 days |

Modular Design Implementation

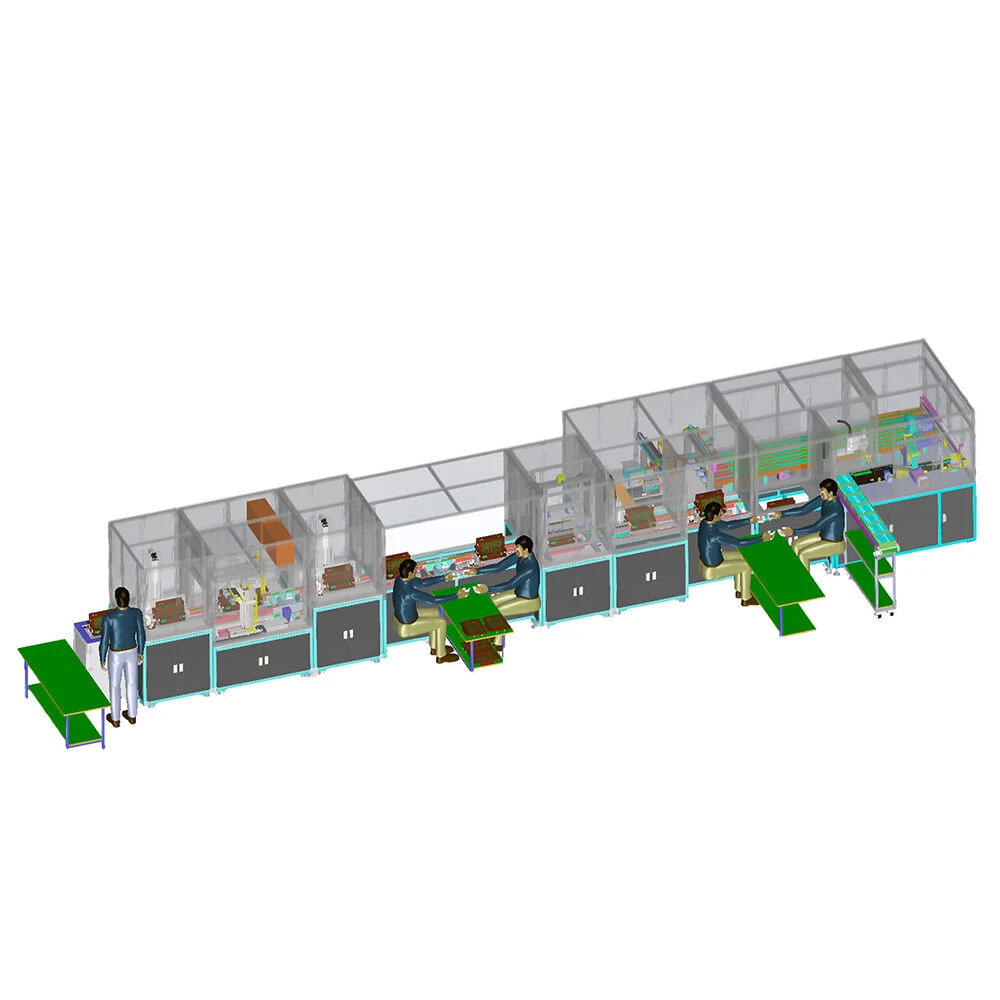

Modern glass windshield sealing strip factories utilize 12-axis CNC molding for precision fitting:

- 3D vehicle frame scanning (±0.15mm accuracy)

- Dual-material bonding (EPDM + TPV composites)

- Automated adhesion testing (5N/mm minimum)

Commercial Vehicle Deployment Metrics

A heavy truck manufacturer achieved 40% maintenance reduction through optimized sealing profiles:

| Parameter | Before | After |

|---|---|---|

| Water Intrusion | 22% vehicles | 3% vehicles |

| Wind Noise | 68 dB | 61 dB |

| Part Weight | 480g/m | 390g/m |

Glass Windshield Sealing Strip Sustainability Initiatives

78% of Tier 1 automotive suppliers now mandate recycled content in glass windshield sealing strips, driving material science innovations. Current development pipelines include:

- Bio-based EPDM from renewable resources

- Self-healing silicone composites

- Integrated moisture sensors

(glass windshield sealing strip)

FAQS on glass windshield sealing strip

Q: What materials are used in your glass windshield sealing strips?

A: Our sealing strips are made from high-quality EPDM rubber or TPV, ensuring durability, weather resistance, and a secure fit for windshields.

Q: How do I choose a reliable glass windshield sealing strip supplier?

A: Look for suppliers with ISO certification, proven manufacturing expertise, and positive client reviews to ensure product quality and reliable service.

Q: Do your factories offer custom windshield sealing strip designs?

A: Yes, we provide tailored solutions for dimensions, materials, and colors to meet specific vehicle models or client requirements.

Q: What quality checks do manufacturers perform on sealing strips?

A: We conduct rigorous tests, including UV resistance, compression tests, and leak detection, to meet automotive industry standards.

Q: What is the typical lead time for bulk orders?

A: Lead times vary by order size, but we prioritize efficiency—typically delivering within 15-30 days with expedited options available.

Share

-

Uses of Jute Bags | Sustainable Jute ProductsNewsAug.12,2025

-

Types of Square Files and Their Uses in Modern IndustriesNewsAug.12,2025

-

Slitting Machines Overview & TypesNewsAug.12,2025

-

Jute Rope: The Versatile Material for DIY & CraftingNewsAug.12,2025

-

How to Use Tofu Cat Litter for the Best ResultsNewsAug.12,2025

-

Car Door Seal Buying GuideNewsAug.12,2025