stainless steel wood file factory

The Art of Stainless Steel Wood Files A Deep Dive into the Factory Production Process

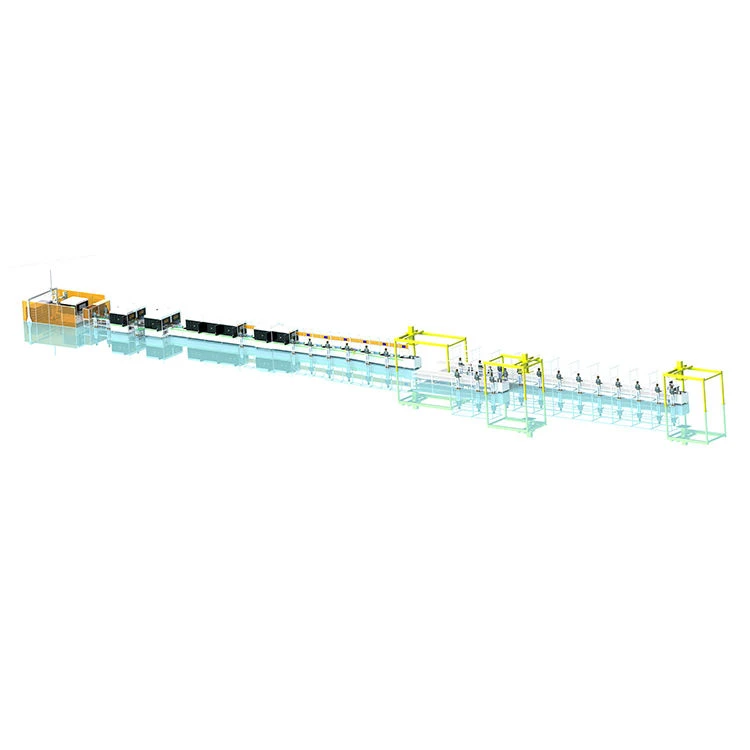

In the world of woodworking, precision and quality are paramount. One of the crucial tools that woodworkers rely on is the file, especially those crafted from stainless steel. These files are not only valued for their durability but also for their ability to refine and shape wood with unparalleled accuracy. This article explores the fascinating process behind the production of stainless steel wood files in a factory setting.

At the heart of any successful stainless steel wood file factory is a commitment to quality and craftsmanship. The journey begins with the selection of high-grade stainless steel, which is known for its resistance to corrosion and wear. This material is essential, as woodworkers often encounter various types of wood, some of which may contain moisture, leading to potential damage. The choice of stainless steel ensures that the files will maintain their effectiveness over time, making them a worthwhile investment for any craftsman.

The Art of Stainless Steel Wood Files A Deep Dive into the Factory Production Process

With the basic shape established, the files undergo a series of grinding processes to achieve the necessary texture and sharpness. Different grits of abrasive materials are employed based on the desired finish and purpose of the file. For instance, finer grits produce smooth surfaces ideal for finishing touches, while coarser grits are designed for aggressive material removal. This meticulous grinding process not only refines the shape but also enhances the tool's effectiveness, making it a reliable partner for woodworkers.

stainless steel wood file factory

As the files begin to take form, it is imperative to ensure consistent quality throughout production. Factories typically implement stringent quality control measures at various stages. This includes visual inspections, measurement checks, and performance tests. Such assessments are essential to meet industry standards and ensure that each file performs optimally. A factory committed to excellence prioritizes these steps, as any flaws can lead to inefficient tools that do not meet the needs of skilled craftsmen.

After passing through quality assurance, the files are ready for surface treatment. This stage often involves polishing and coating the files to enhance their durability and aesthetic appeal. A well-polished file not only looks professional but also reduces friction during use, making woodworking processes smoother. The application of protective coatings further enhances resistance to corrosion, prolonging the life of the tools.

Finally, once the files are fully manufactured and treated, they are packaged and prepared for distribution. Suppliers must work swiftly to ensure that woodworkers have access to these essential tools. Proper packaging is critical to protect the files during shipping and storage, ensuring that customers receive products in pristine condition. Catalogs or online platforms detail the specifications of each file, allowing customers to choose the most suitable tools for their projects.

In conclusion, the production of stainless steel wood files in a factory setting is a blend of art and science. From the careful selection of raw materials to the meticulous shaping, grinding, and finishing processes, every step is dedicated to creating high-quality tools that woodworkers can rely on. As the woodworking industry continues to evolve, the demand for durable and effective tools will remain strong, making the stainless steel wood file a timeless essential in any craftsman's toolkit. Embracing innovation while honoring traditional craftsmanship ensures that these files will continue to serve professionals and hobbyists alike for years to come.

Share

-

Flat Rasp Techniques for Metal Surface FinishingNewsAug.22,2025

-

Can a Faulty Car Door Seal Cause Wind Noise?NewsAug.22,2025

-

How Rolling Roller Technology Improves Battery Production EfficiencyNewsAug.22,2025

-

Major Obstacles to Automating a Car Battery Assembly LineNewsAug.22,2025

-

The Role of Slitting Machines in Lithium Battery Electrode ManufacturingNewsAug.22,2025

-

Key Challenges in Lithium Battery Production Line OptimizationNewsAug.22,2025