Wholesale High-Quality High-Pressure Rubber Seals for Various Industrial Applications

Wholesale High Pressure Rubber Seals An Essential Component for Various Industries

In the realm of industrial applications, seals play a crucial role in ensuring the efficiency and safety of machinery. Among the various types of seals available, high pressure rubber seals have emerged as a vital component, particularly in industries that rely on high-pressure systems. This article delves into the significance, features, and applications of wholesale high pressure rubber seals.

Understanding High Pressure Rubber Seals

High pressure rubber seals are designed to withstand extreme pressures, making them essential for systems that operate under such conditions. These seals are typically made from a variety of rubber compounds, each chosen for its durability, flexibility, and resistance to wear and tear. Common materials include nitrile rubber (NBR), fluorocarbon rubber (FKM), and silicone rubber, each offering unique properties that suit different operational needs.

Key Features of High Pressure Rubber Seals

1. Pressure Resistance As the name implies, these seals are engineered to handle high pressure scenarios. Their design minimizes the risk of leaks and prevents material failure under extreme conditions. 2. Temperature Tolerance Many high pressure rubber seals can tolerate a wide range of temperatures, making them suitable for both hot and cold environments. This feature is crucial for maintaining seal integrity during thermal expansion and contraction of connected components.

3. Chemical Compatibility Different industries utilize various fluids, often chemical in nature. High pressure rubber seals are available in compounds that provide resistance to a wide range of chemicals, ensuring that they do not degrade when exposed to harsh substances.

4. Durability and Longevity The robust nature of high pressure rubber seals allows them to maintain functionality over extended periods, reducing the need for frequent replacements and minimizing maintenance costs for businesses.

Applications Across Industries

High pressure rubber seals find applications in numerous sectors, showcasing their versatility

wholesale high pressure rubber seals

- Oil and Gas In oil drilling and production, high pressure rubber seals are critical for ensuring that pipelines and storage tanks do not leak under high-pressure conditions

. Their resistance to corrosive substances makes them particularly valuable in this sector.- Automotive The automotive industry employs high pressure rubber seals in various components such as engines, transmissions, and braking systems. These seals help maintain pressure while preventing fluid leaks, which is essential for vehicle safety and performance.

- Manufacturing and Machinery Heavy machinery and manufacturing equipment often operate under high pressures. High pressure rubber seals are integral in hydraulic systems, compressors, and pumps, ensuring they function effectively.

- Medical Equipment In the medical field, equipment that requires sterile environments or high-pressure systems, such as autoclaves, rely on high quality rubber seals to maintain efficacy and safety standards.

Sourcing Wholesale High Pressure Rubber Seals

When it comes to purchasing high pressure rubber seals, sourcing them wholesale can lead to significant cost savings for businesses. Wholesale suppliers often provide bulk pricing, which is beneficial for companies that require large quantities for ongoing projects. Additionally, buying in bulk ensures consistency in seal performance and quality across applications.

It is essential for businesses to choose a reputable wholesale supplier that offers a range of rubber compounds and seal designs to meet their specific needs. Factors such as certification compliance, product guarantees, and customer service should be considered to ensure a reliable partnership.

Conclusion

Wholesale high pressure rubber seals serve a pivotal role across various industries, providing safety, efficiency, and durability in high-pressure applications. Their robust design and resistance to extreme conditions make them an indispensable component in modern machinery and systems. As industries continue to evolve, the demand for high-quality rubber seals will likely grow, prompting innovations tailored to meet the changing needs of the market.

Share

-

Uses of Jute Bags | Sustainable Jute ProductsNewsAug.12,2025

-

Types of Square Files and Their Uses in Modern IndustriesNewsAug.12,2025

-

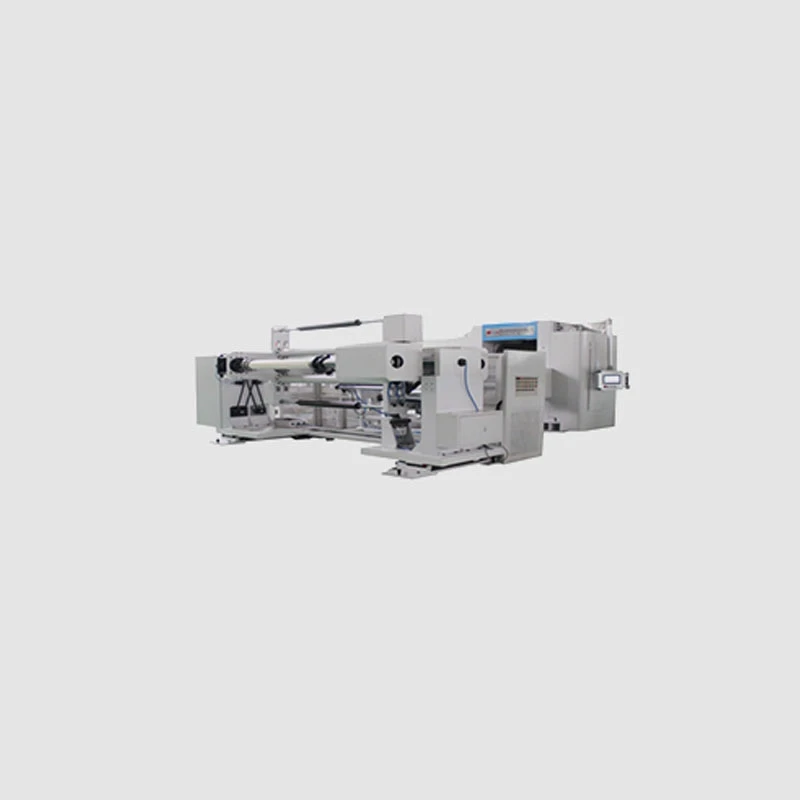

Slitting Machines Overview & TypesNewsAug.12,2025

-

Jute Rope: The Versatile Material for DIY & CraftingNewsAug.12,2025

-

How to Use Tofu Cat Litter for the Best ResultsNewsAug.12,2025

-

Car Door Seal Buying GuideNewsAug.12,2025