window rubber seals for cars manufacturer

Window Rubber Seals for Cars A Key Component in Automotive Manufacturing

When it comes to the automotive industry, every component plays a crucial role in the overall functionality and durability of the vehicle. Among these components, window rubber seals might not be the first thing that comes to mind, but they are essential for ensuring a car's performance, comfort, and safety. As a specialized manufacturer of window rubber seals for cars, it’s important to understand not only the function of these components but also the manufacturing processes involved and the materials used.

The Importance of Window Rubber Seals

Window rubber seals, also known as weatherstripping, are designed to create a tight seal around the windows of a vehicle. These seals serve multiple functions, including preventing water, wind, and dust from entering the vehicle. They also play a significant role in reducing noise levels inside the car, providing an overall more comfortable driving experience. Moreover, high-quality seals contribute to the longevity of the vehicle’s interior by shielding it from sun exposure and damp conditions that could lead to mold or deterioration of materials.

Materials Used in Manufacturing

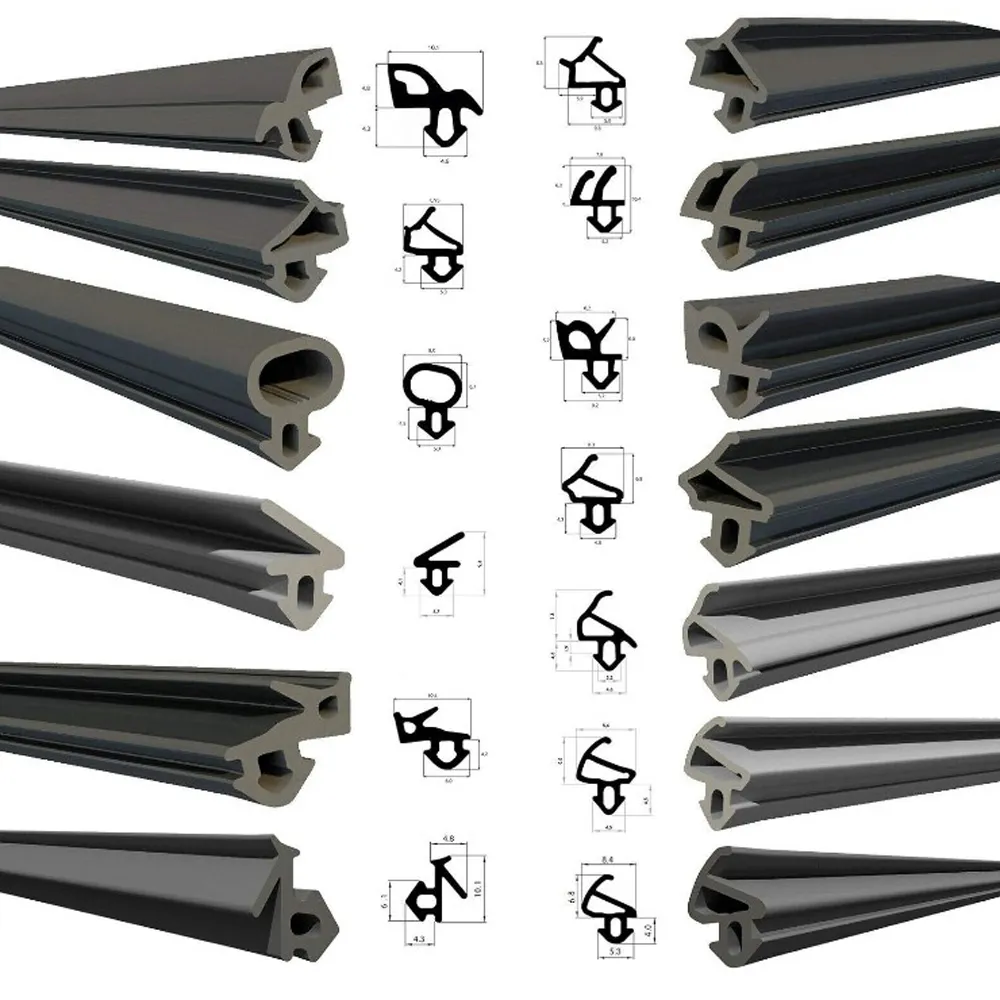

The materials used in producing window rubber seals are primarily rubber-based, often compounded with various additives to enhance their performance. Common materials include natural rubber, synthetic rubber (such as EPDM, neoprene, and TPE), and thermoplastic elastomers. Each material has its unique properties, such as flexibility, durability, resistance to UV light, and extreme temperatures, which makes the selection of material critical based on the specific requirements of the vehicle and the environment in which it will operate.

Manufacturers must carefully consider factors such as the vehicle's design specifications, climate conditions, and the expected wear and tear when choosing the right materials for window seals. For instance, vehicles intended for regions with extreme weather conditions require seals that can withstand temperature fluctuations without losing their effectiveness.

Manufacturing Processes

window rubber seals for cars manufacturer

The production of window rubber seals involves several intricate processes aimed at ensuring precision and quality. Initial steps include material formulation, where the rubber and additives are mixed in exact proportions to achieve desired properties. This mixture is then formed into specific shapes using methods such as extrusion and compression molding.

Extrusion, one of the most common methods, involves forcing the rubber mixture through a mold to create continuous shapes, which are then cut to the desired length. Compression molding, on the other hand, involves placing rubber into a mold and applying heat and pressure to create a finished part. Both methods require careful monitoring to ensure consistency and quality control.

Following the molding processes, seals undergo further treatments such as curing or vulcanization, which ensure enhanced strength and durability. This process adds cross-links between rubber molecules, resulting in a material that can withstand the demands of daily use.

Quality Control and Testing

Quality control is paramount in the manufacturing of window rubber seals. Given their role in maintaining a vehicle’s integrity, these seals undergo rigorous testing for durability, flexibility, and resistance to various environmental conditions. Manufacturers often utilize specialized equipment to simulate real-world conditions, assessing each seal’s performance over time.

Furthermore, adherence to industry standards and regulations is vital. Certifications such as ISO ensure that manufacturers meet specific quality benchmarks, ultimately delivering reliable products to automotive manufacturers.

Conclusion

As a key player in the automotive supply chain, window rubber seal manufacturers play an essential role in the safety, comfort, and longevity of vehicles. By using advanced materials and manufacturing techniques while maintaining high-quality standards, these manufacturers ensure that their products fulfill the demanding requirements of modern automotive design. Window rubber seals may be small in size, but their impact on vehicle performance is significant, contributing to a seamless driving experience. As technology evolves, the continuous improvement of these seals will undoubtedly enhance vehicle efficiency and user satisfaction.

Share

-

Flat Rasp Techniques for Metal Surface FinishingNewsAug.22,2025

-

Can a Faulty Car Door Seal Cause Wind Noise?NewsAug.22,2025

-

How Rolling Roller Technology Improves Battery Production EfficiencyNewsAug.22,2025

-

Major Obstacles to Automating a Car Battery Assembly LineNewsAug.22,2025

-

The Role of Slitting Machines in Lithium Battery Electrode ManufacturingNewsAug.22,2025

-

Key Challenges in Lithium Battery Production Line OptimizationNewsAug.22,2025