steel pick sharpened steel file factories

The Evolution of Steel Pick and Sharpened Steel Files A Look into Factories

In the realm of tools and industrial equipment, the significance of high-quality steel picks and sharpened steel files cannot be overlooked. These instruments, which are pivotal in various sectors such as construction, manufacturing, and woodworking, owe much of their evolution and functionality to advanced manufacturing processes. In this article, we will explore the intricacies involved in the production of these essential tools, the factories that bring them to life, and the advancements that have shaped their development over the years.

Understanding Steel Picks and Steel Files

Steel picks are specialized tools often used for extracting materials, shaping surfaces, or removing excess material. They come in various shapes and sizes, each designed for specific tasks, from mining to landscaping. On the other hand, sharpened steel files are essential for smoothing rough edges, shaping materials, and fitting components together accurately. Both tools are integral to achieving precision and efficiency in various trades.

The Manufacturing Process

The manufacturing of steel picks and files involves several crucial steps, beginning with the selection of high-quality steel. Factories often source steel of different grades, each suitable for specific applications. High carbon steel, known for its toughness and ability to hold sharp edges, is commonly used in making steel files. Similarly, steel picks may require additional properties such as corrosion resistance, which influences the choice of materials.

Once the steel is procured, it undergoes a series of processes including forging, machining, and heat treatment. Forging involves shaping the heated metal with hammers or presses, a process that enhances its strength and durability. For files, precision machining comes into play to create the distinctive teeth pattern that enables efficient material removal.

Heat treatment is another crucial step that improves the hardness and wear resistance of steel tools. In many factories, advanced computerized systems oversee these processes, ensuring high precision and consistency.

Quality Assurance and Testing

steel pick sharpened steel file factories

In modern factories, quality assurance plays a vital role in the manufacturing of steel picks and files. Each batch undergoes rigorous testing to meet industry standards. Factories often employ methods such as tensile testing, hardness testing, and microscopic examinations to verify the structural integrity of the tools. This focus on quality not only ensures safety but also enhances the longevity and performance of the tools.

The Role of Technology

Technological advancements have revolutionized the way steel picks and files are manufactured. Automation and robotics have significantly increased production efficiency, allowing factories to meet higher demands while maintaining quality. CNC (Computer Numerical Control) machines have provided unparalleled precision in machining processes, enabling the creation of intricate designs and patterns that improve the performance of tools.

Furthermore, the rise of sustainable manufacturing practices has prompted factories to adopt environmentally-friendly methods. From the use of recycled materials to energy-efficient machinery, these practices not only reduce the environmental impact but also appeal to a growing base of eco-conscious consumers.

Future Trends

Looking ahead, the industry of steel picks and sharpened steel files is poised for continuous evolution. With an increasing emphasis on customization, manufacturers may offer tailor-made solutions for specific applications, catering to niche markets. Additionally, as industries evolve, the demand for specialized tools capable of handling new materials and technologies, such as composites and advanced alloys, is likely to increase.

The integration of smart technologies and IoT (Internet of Things) in manufacturing plants signifies a promising future. Factories could leverage data analytics for predictive maintenance, ensuring that tools are produced and maintained efficiently, thus reducing downtime and enhancing productivity.

Conclusion

In summary, the manufacturing of steel picks and sharpened steel files is a complex and evolving process. The factories that produce these essential tools embody a blend of tradition and innovation, where skilled craftsmanship meets modern technology. As industries continue to shift and adapt, the importance of high-quality tools will remain paramount. The future holds exciting possibilities for the evolution of steel picks and files, driven by technological advancements, quality assurance, and a commitment to sustainability. These tools will undoubtedly continue to play a crucial role in shaping various trades for years to come.

Share

-

flat-rasp-techniques-for-metal-surface-finishingNewsAug.22,2025

-

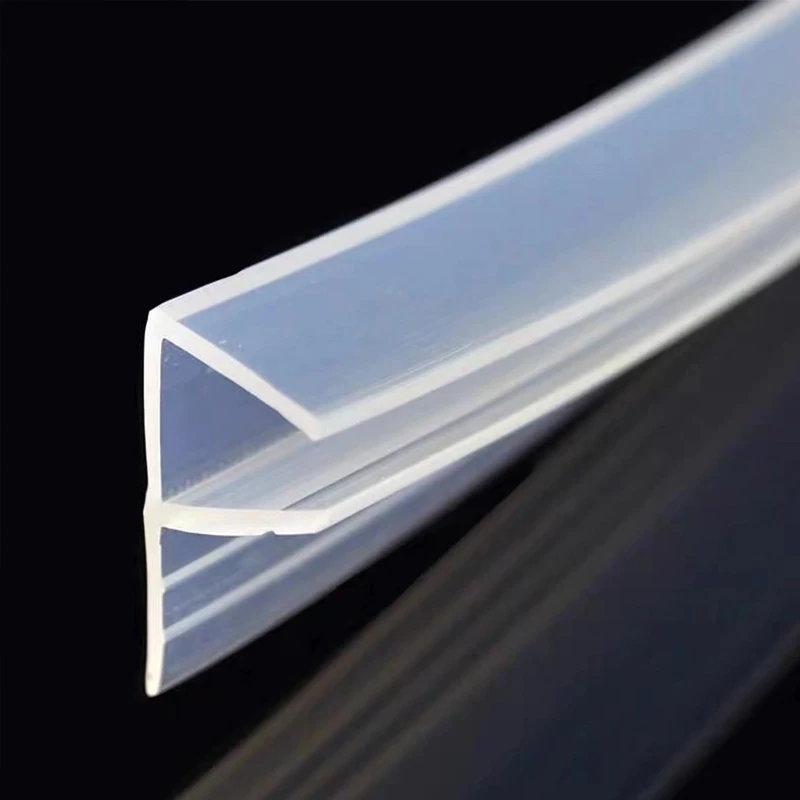

can-a-faulty-car-door-seal-cause-wind-noiseNewsAug.22,2025

-

how-rolling-roller-technology-improves-battery-production-efficiencyNewsAug.22,2025

-

major-obstacles-to-automating-a-car-battery-assembly-lineNewsAug.22,2025

-

the-role-of-slitting-machines-in-lithium-battery-electrode-manufacturingNewsAug.22,2025

-

key-challenges-in-lithium-battery-production-line-optimizationNewsAug.22,2025