Casement Window Rubber Seal | Weatherproof, Quiet, Durable

The Real-World Guide to casement window rubber seal performance

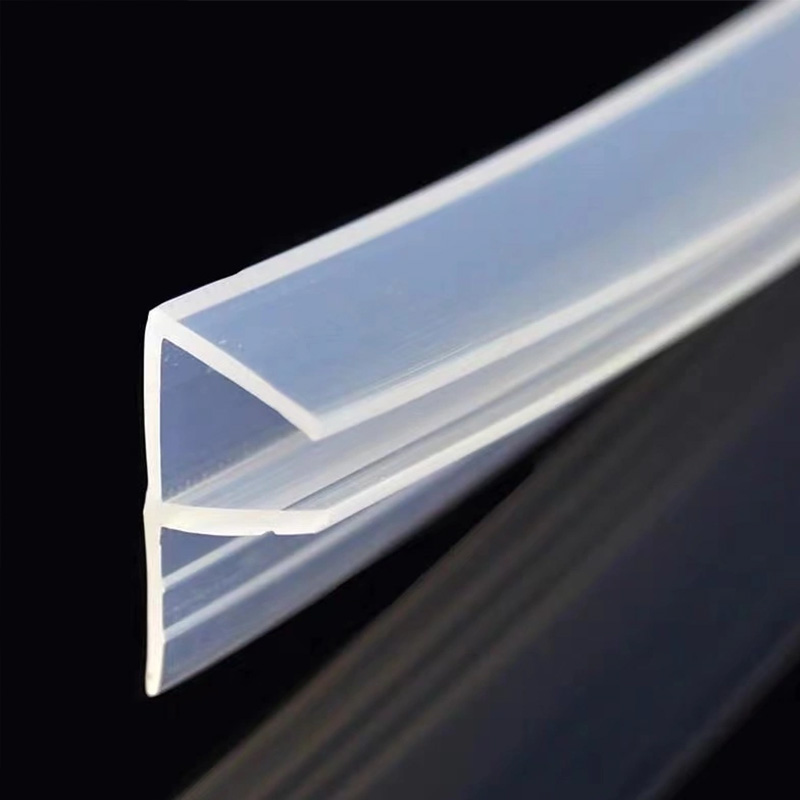

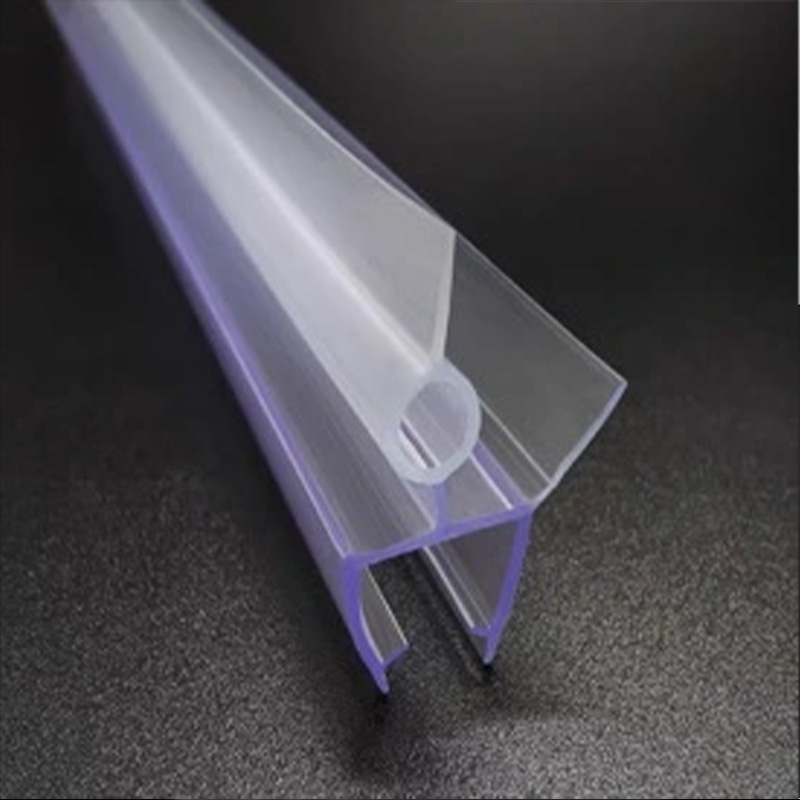

In window factories, you hear the same thing again and again: the seal makes or breaks the sash. That’s why the materials used in a casement window rubber seal—often EPDM, silicone, or TPE blends—matter a lot more than the catalog photos. Quick note: the profile shown here is the “Shower door seal strip,” but in practice the same extrusion families and compounds are widely adapted for windows and doors (co-extruded fins, bubble gaskets, glazing lips). Many customers say the right compound is a quiet upgrade you only notice on a windy night.

Industry trends and where seals are heading

Three shifts stand out: co-extrusion (rigid PP spine with soft EPDM lips), lower compression set compounds for longer service life, and better recyclability. Also, surprisingly, more window brands ask for pre-applied tapes and corner-vulcanized frames to speed assembly. It seems that coastal markets are demanding higher UV/ozone grades as well.

Typical specifications (adaptable by mold)

| Material options | NR/EPDM/NBR/SBR/FKM/PP/PVC/TPR/TPE/TPU/TPV/Silicone |

| Hardness (Shore A) | ≈ 45–75 (foam cores 10–25); ISO 868 |

| Temperature range | EPDM: -40 to +120°C; Silicone: -60 to +200°C |

| Compression set | ≤ 25% @ 70°C, 22h (real-world use may vary) |

| Colors | Black standard; custom on request |

| Certifications | RoHS/REACH compliant; ISO 9001 plant |

Process flow and testing (how it’s really made)

- Compounding (EPDM with peroxides, anti-ozonants, fillers) → Extrusion → Salt-bath or hot-air vulcanization → Co-extrusion with PP if needed → Cutting, corner vulcanization, or frame welding → 100% dimension check → Packaging.

- Tests: Tensile (ISO 37), Hardness (ISO 868), Compression set (ISO 815), Ozone/UV (ASTM D1149), Air/water leakage on frames (ASTM E283/E331 or BS 6375-1). Service life for EPDM: around 10–20 years depending on UV and compression cycles.

Applications and field feedback

For residential casements, high-rise curtain walls, and coastal villas, a casement window rubber seal with low compression set keeps latching smooth. One Southeast Asia project reported ≈35% improvement in air-leakage class after switching to an EPDM bubble + PP carrier profile. Installers liked the pre-applied acrylic tape—“faster than wet glazing,” they told me. To be honest, the quieter close sold it.

Vendor comparison (indicative)

| Vendor | Lead time | MOQ | Certs | Notes |

|---|---|---|---|---|

| Shuoding (Hebei, China) | ≈ 10–18 days | Low (by mold) | ISO 9001, RoHS/REACH | Custom profiles, co-extrusion, corner vulcanization |

| EU Brand A | 3–5 weeks | Medium | EN 12365 classes | Strong coastal UV grades |

| Local Fabricator B | 1–2 weeks | Very low | Varies | Fast repeats, limited polymers |

Customization and sourcing

Sizes by mold, colors as requested. Material picks: EPDM for weathering, Silicone for extreme temps, TPE for snap-in glazing. Origin: Room 1410, No. 119 Zhongxing East Street, Xiangdu District, Xingtai City, Hebei Province, China. If you’re specifying a casement window rubber seal, ask for: durometer, bulb recovery after 10k cycles, and EN 12365 classification data.

Case mini-study

A retrofit in a windy, dry climate swapped aging PVC gaskets for EPDM + PP spine. Results after lab checks: tensile 8–10 MPa (ISO 37), compression set 18% (ISO 815), no cracks after 72h ozone (ASTM D1149). Field noise dropped ≈2 dB at 6 m/s wind. Not dramatic, but occupants noticed—“windows don’t whistle anymore,” the site manager joked.

Citations

- ASTM E283/E331 – Air and Water Penetration Tests for Windows and Doors.

- ISO 37, ISO 815, ISO 868 – Rubber: Tensile, Compression Set, Hardness.

- ASTM D1149 – Ozone Resistance of Rubber.

- EN 12365-1 – Performance classification of gaskets for doors, windows, and curtain walling.

Share

-

Lithium Battery Welding Machine | High-Precision, Fast, SafeNewsNov.17,2025

-

Aluminium Guide Roller | Anodized, Lightweight, Low-NoiseNewsNov.17,2025

-

Tofu Cat Litter Bulk – Eco, Low-Dust, Fast Clumping SupplyNewsNov.17,2025

-

Equipment for Lithium Cell Assembly | Automated & PreciseNewsNov.10,2025

-

Square File Tool – Precision Cut, Hardened Steel, VersatileNewsNov.10,2025

-

Lithium Ion Battery Assembly Machine | Automated, High-SpeedNewsNov.10,2025