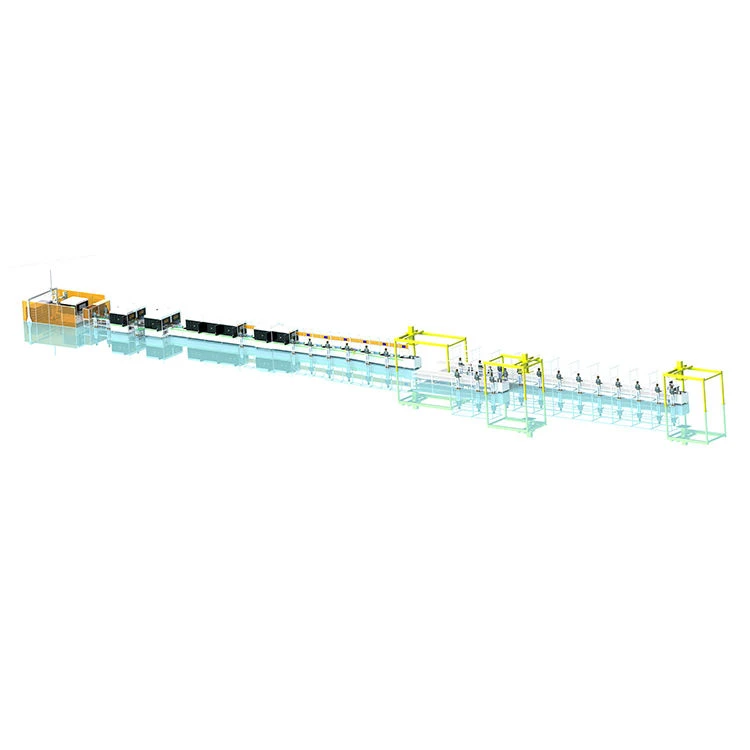

Filling Machine for lithium battery Injection Production Line

The ever-evolving landscape of battery technology demands a sophisticated and meticulous approach to production, where precision, efficiency, and innovation are pivotal. As the global push towards electrification gains momentum, battery production equipment lines have emerged as the backbone of the industry, enabling large-scale manufacturing of high-performance batteries.

An exceptional battery production line integrates a series of complex, yet seamlessly interwoven processes designed to enhance productivity and quality while minimizing waste and energy consumption. These lines typically encompass several critical stages, including electrode production, cell assembly, electrolyte filling, battery formation, and testing, all of which require specialized equipment.

One of the key elements in a battery production equipment line is the electrode coating machine. Precision in electrode fabrication is paramount, as it directly influences the battery's capacity and lifespan. Cutting-edge coating technologies ensure uniformity and thickness control, which are critical for achieving high energy density and efficient charge-discharge cycles. Advanced systems use automated controls and inline monitoring to maintain consistency and optimize material usage, thereby enhancing cost efficiency.

During the cell assembly phase, the industry has seen notable advancements in automation and robotics. Modern battery assembly lines utilize robotic arms and automated transport systems to meticulously piece together the battery components. This automation reduces the risk of contamination and human error, significantly enhancing reliability. Additionally, the integration of AI-driven analytics allows for real-time monitoring of the assembly process, ensuring that any anomalies are promptly identified and rectified.

Electrolyte filling is another crucial step, where precision dispensing equipment ensures the accurate injection of electrolytes into battery cells. This process demands exactness to prevent overfilling or underfilling, which could compromise battery performance and safety. State-of-the-art filling machines are equipped with advanced sensors and feedback loops, delivering unparalleled accuracy and consistency.

battery production equipment line

Battery formation and testing phases underscore the importance of reliability in production lines. Formation equipment facilitates the initial charge and discharge cycles that activate the chemical reactions within the battery. It is crucial for establishing battery capacity and performance characteristics. Sophisticated formation systems offer customizable charge profiles and comprehensive data logging, enabling manufacturers to fine-tune their processes and guarantee product quality.

Quality control is imperative in any battery production line. With the rise of smart manufacturing, there is an increased emphasis on implementing stringent testing protocols. Thermal imaging, X-ray inspection, and electrical testing are integrated into production lines to detect defects early on, preventing faulty products from reaching the market.

Trustworthiness and authority in battery production are built on a foundation of continuous research and development, adherence to international standards, and the adoption of cutting-edge technologies. By maintaining a robust and efficient battery production equipment line, manufacturers can meet the growing demand for sustainable energy solutions while ensuring that their products set new benchmarks in quality and performance.

In conclusion, a well-designed battery production equipment line is not only a testament to a manufacturer's expertise and commitment to excellence but also a crucial factor in gaining a competitive edge in the rapidly evolving energy storage sector. The integration of advanced technologies, coupled with rigorous quality control measures, assures that modern battery production lines are equipped to meet the highest standards of reliability, efficiency, and environmental responsibility.

Share

-

The Ultimate Guide to Square Files for Precision WorkNewsJun.26,2025

-

The Power of Flat FilesNewsJun.26,2025

-

Revolutionize Your Craft with High-Performance Rotary FilesNewsJun.26,2025

-

Precision and Durability with Diamond-Coated Needle FilesNewsJun.26,2025

-

Essential Tools for Precision Work: Round Metal Files and MoreNewsJun.26,2025

-

Essential Tools for Precision Sharpening: Triangular FilesNewsJun.26,2025