Cylindrical Cell Manufacturing: Faster, Safer—Why Choose Us?

Inside the 18650/21700/26650/32650 Cylindrical Cell Production Line

I’ve walked more than a few battery factories, but the most recent visit to Xingtai in Hebei stuck with me. The hum of slitters, the smell of solvent recovery, that careful quiet during formation—this is where cylindrical cell manufacturing earns its reputation for consistency. The line I saw turns out steel-can LiFePO4 cells in mainstream formats—18650, 21700, 26650, 32650—aimed at solar lighting, lawn fixtures, backup energy, tools, and even hobby models.

Trends I’m Seeing

Honestly, not everything is about 4680s. The quiet workhorses—18650 and 21700—keep growing in industrial and light-mobility niches. LFP’s rise (for safety and cycle life) has been steady, and steel cans remain popular for abuse tolerance. Meanwhile, automation density is going up while energy costs push factories to tighter solvent recovery and better calendaring control. It’s not flashy; it’s reliable. And that sells.

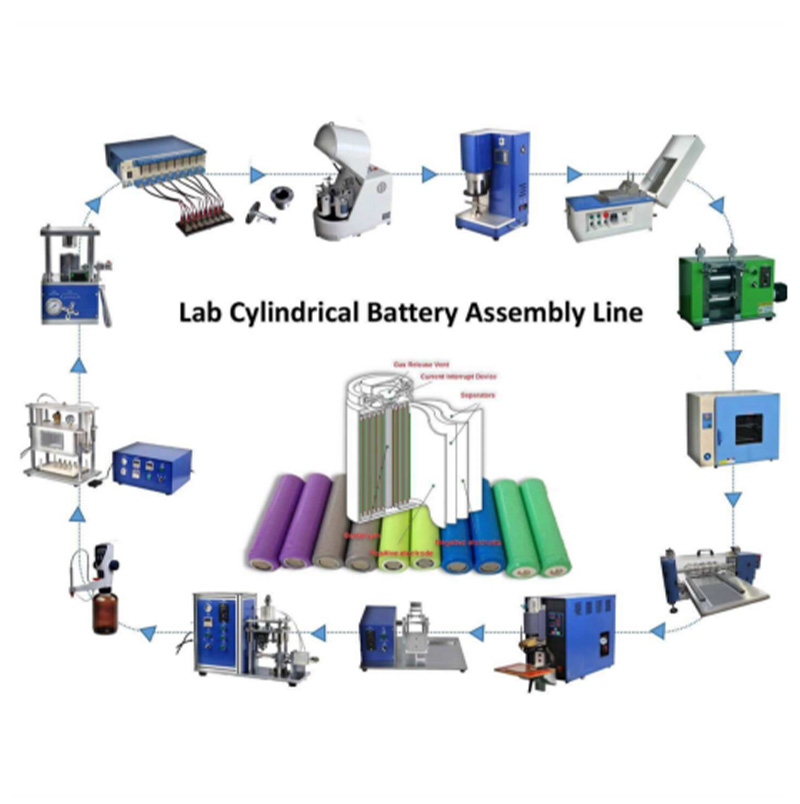

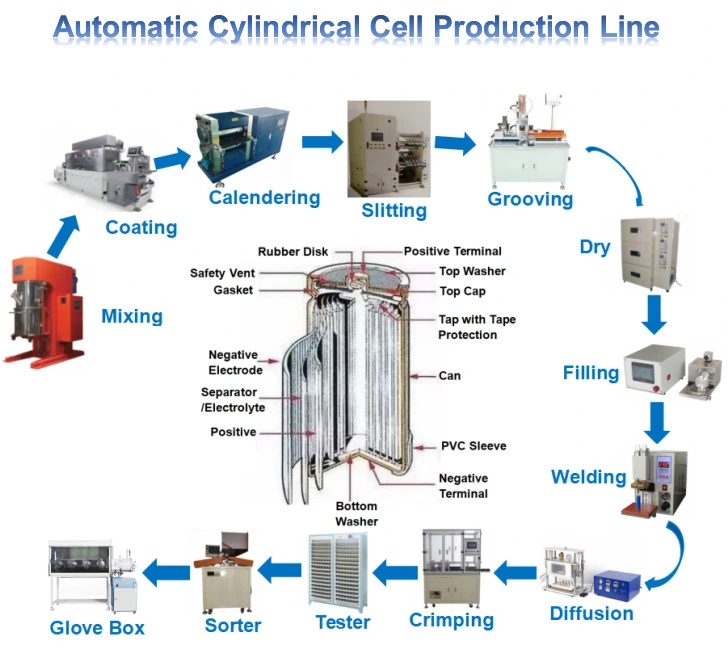

Process Flow (What Actually Happens)

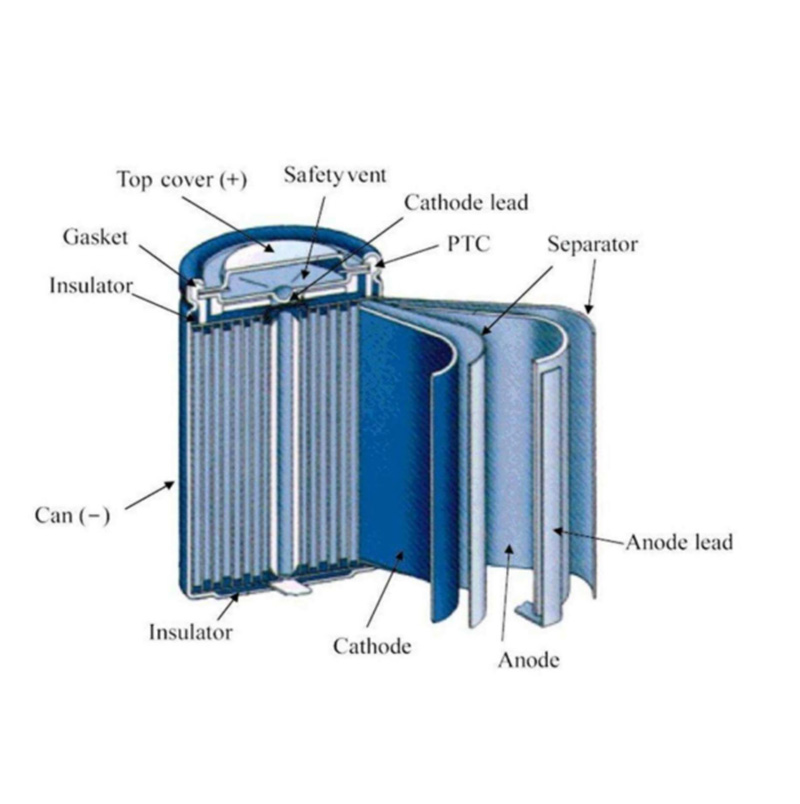

Materials: LFP cathode powder, graphite anode, PVDF binder, Super P conductive additive, PP/PE separator, LiPF6 in EC/EMC/DEC electrolyte, nickel-plated steel can, laser-weldable tabs.

- Slurry prep and vacuum deaeration (viscosity control is everything).

- Coating and drying on both sides, then calendaring to target porosity.

- Slitting with burr management, dust mitigation.

- Winding the “jelly roll,” tab welding, can insertion.

- Electrolyte filling (vacuum), rest soak, crimping/helium leak check.

- Formation cycles (CC/CV), degassing, final seal.

- OCV/ACIR test, capacity grading, traceability QR assignment.

Standards routinely referenced: UN 38.3 transport, IEC 62133-2 safety for portables, UL 1642 cell safety. In one recent lot, example post-formation OCV was ≈3.28–3.30 V (LFP), ACIR around 18–28 mΩ (18650 class). Real-world use may vary, of course.

Key Specs at a Glance

| Format | Nominal V | Capacity (LFP) ≈ | Max Cont. Discharge ≈ | Cycle Life | Operating Temp |

|---|---|---|---|---|---|

| 18650 | 3.2 V | 1.5–1.8 Ah | 5–10 A | ≥2,000 @80% | -20 to 60°C |

| 21700 | 3.2 V | 2.4–3.3 Ah | 10–15 A | ≥2,000 @80% | -20 to 60°C |

| 26650 | 3.2 V | 3.0–4.0 Ah | 15–20 A | ≥2,000 @80% | -20 to 60°C |

| 32650 | 3.2 V | 5.0–6.5 Ah | 20–30 A | ≥2,000 @80% | -20 to 60°C |

Cycle life at 25°C, 0.5C/0.5C to 80% retention; around 5–10 years of service life in moderate climates.

Applications and Field Notes

You’ll find these in solar garden lights, lawn fixtures, UPS/backup modules, cordless tools, and toy models. One municipal pilot we tracked swapped aging lead-acid in solar streetlights for 32650 LFP packs; maintenance visits dropped by ~60% in year one, which—frankly—got the finance folks smiling. Another integrator reported cooler pack temps in power tools under continuous load versus older chemistries.

Vendor Comparison (Quick, pragmatic)

| Vendor | Automation Level | Yield ≈ | Lead Time | After-Sales | Certs |

|---|---|---|---|---|---|

| XTSHuoding Line (Hebei) | High (inline OCV/IR, auto fill/degassing) | ≈95–98% | Around 8–12 weeks | Onsite + remote | ISO 9001/14001, UN 38.3-ready |

| Generic Turnkey | Medium | ≈92–95% | 10–16 weeks | Remote only | ISO 9001 |

| Custom Integrator | Variable | ≈90–97% | 12–24 weeks | Project-based | Depends |

Note: Yields depend on materials, training, and environment. Real-world use may vary.

Customization and Compliance

Tab geometry, can finish, internal resistance targets, and BMS-ready leads are all customizable. Batch-level traceability is standard. Certifications pursued typically include ISO 9001/14001 at the site level, plus cell testing to UN 38.3, IEC 62133-2, and often UL 1642 for North America. The facility I visited is based at Room 1410, No. 119 Zhongxing East Street, Xiangdu District, Xingtai City, Hebei, China—nice coffee nearby, by the way.

If you care about dependable, safe packs, cylindrical cell manufacturing with LFP chemistry is a solid, boring-in-a-good-way choice. Stable voltage, long cycle life, and friendly safety behavior under abuse—overcharge, short-circuit, you name it—are why many customers keep coming back.

References

Share

-

Lithium Battery Welding Machine | High-Precision, Fast, SafeNewsNov.17,2025

-

Aluminium Guide Roller | Anodized, Lightweight, Low-NoiseNewsNov.17,2025

-

Tofu Cat Litter Bulk – Eco, Low-Dust, Fast Clumping SupplyNewsNov.17,2025

-

Equipment for Lithium Cell Assembly | Automated & PreciseNewsNov.10,2025

-

Square File Tool – Precision Cut, Hardened Steel, VersatileNewsNov.10,2025

-

Lithium Ion Battery Assembly Machine | Automated, High-SpeedNewsNov.10,2025