Wholesale Dog Food: Bulk Pricing, Fast Shipping

A practical buyer’s guide to Wholesale Dog Food (from someone who’s actually toured the plants)

If you’re scaling pet nutrition—private label, chain retail, or shelters—the kibble you choose affects returns, reviews, and honestly, how your brand smells (literally). I’ve sat in extrusion rooms, watched steam curves, and tasted a kibble or two—don’t recommend. Below is what matters now, and what many buyers quietly ask behind closed doors.

What’s inside: materials and methods

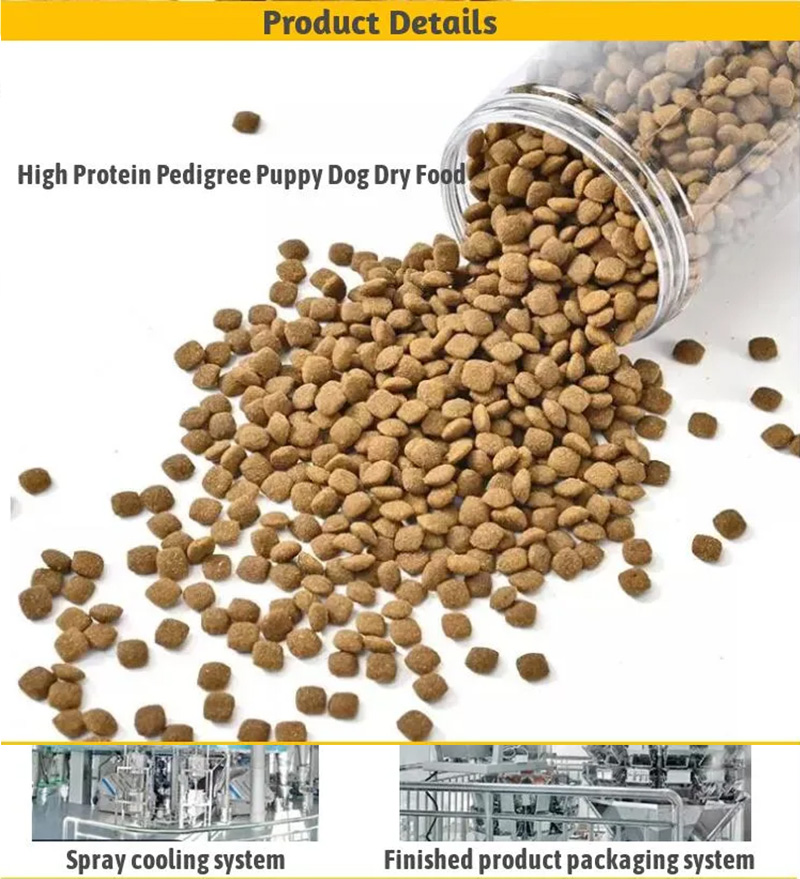

Product name: Dog food. Dogs are omnivores with a carnivorous bias—short GI tracts, great at protein and fat, yet equipped with amylase genes for starch digestion. The best Wholesale Dog Food formulas strike a balance: animal protein first, digestible carbs, functional fiber, and sensible fats.

- Typical inputs: chicken meal or fresh poultry, beef or fish meal, rice or sorghum, beet pulp, poultry fat, brewer’s yeast, vitamins/minerals, natural preservatives (mixed tocopherols).

- Processes: high-shear extrusion (common), cold-press (niche), oven-baked (marketing-friendly), vacuum coating for palatability and stable fats.

| Parameter | Spec (≈) | Notes |

|---|---|---|

| Crude Protein | 26–30% | Adult all-breed baseline |

| Crude Fat | 12–16% | Energy density and flavor |

| Crude Fiber | 3–5% | Stool quality |

| Moisture | ≤10% | Shelf-life driver |

| Kibble size | 8–14 mm | Breed-specific options |

| ME (kcal/kg) | 3,400–3,800 | Calculated, AAFCO basis |

| Shelf life | 18–24 months | Cool, dry storage |

Process flow, testing, and service life

- Material intake → grinding → preconditioning → extrusion → drying → vacuum fat coating → cooling → metal detection → packing.

- Testing: proximate analysis, microbiology (Salmonella, Enterobacteriaceae), mycotoxins (aflatoxin B1), peroxide value, water activity (aw), and palatant consistency.

- Standards often referenced: AAFCO nutrient profiles, FEDIAF guidelines, ISO 22000/HACCP for food safety.

- Service life: 18–24 months sealed; after opening, recommend use within 6–8 weeks.

- Industries: retail chains, e-commerce DTC, vet clinics, breeders, animal shelters, private-label brands.

| Vendor | Certs/Standards | MOQ | Lead Time | Origin |

|---|---|---|---|---|

| XT Shuoding (Dog food) | ISO 22000/HACCP; aligns with AAFCO/FEDIAF | ≈ 2–5 tons | 15–25 days | Room 1410, No. 119 Zhongxing East Street, Xiangdu, Xingtai, Hebei, China |

| Regional Co-Packer A | FSSC 22000 | ≈ 10 tons | 30–45 days | Southeast Asia |

| EU Private Label B | IFS; BRCGS | ≈ 5–8 tons | 25–35 days | EU |

Customization, real feedback, and use cases

- Custom options: protein sources (poultry, fish, lamb), grain-free vs. ancient grains, joint or skin-health packs, kibble shapes, retail vs. bulk sacks, bilingual labeling.

- COA snapshot (example): Salmonella ND; Moisture 9.6%; Peroxide value within spec; Aflatoxin B1 ≤ 5 ppb.

- Customer notes: “Palatability jumped after switching to vacuum-coated fats,” one midwest retailer told me; “returns dropped ≈20%.”

- Scenarios: shelters needing cost-per-bowl stability; DTC brands seeking recurring subscription-friendly SKUs; vets wanting limited-ingredient lines.

Compliance and labeling—don’t wing it

Check local label rules, ingredient statements, and nutritional adequacy claims. Many suppliers design to AAFCO/FEDIAF, but you must verify with finished-product testing and keep HACCP records. It sounds dull—until customs asks for it.

Quick buying tips

- Ask for extrusion logs, aw targets, and finished product COAs per lot.

- Pilot first: 1–2 pallets to test palatability and stool quality with real customers.

- Lock pallets with ≤10% moisture and oxygen-barrier bags for longer shelf life.

Bottom line: a well-made Wholesale Dog Food program blends sound formulation, disciplined process control, and honest QC. When those line up, you feel it in repeat orders.

- Association of American Feed Control Officials (AAFCO) Dog Food Nutrient Profiles.

- FEDIAF Nutritional Guidelines for Complete and Complementary Pet Food for Cats and Dogs.

- ISO 22000: Food safety management systems — Requirements for any organization in the food chain.

- FDA CVM Guidance on Salmonella in animal feed and pet food (FSMA context).

Share

-

Lithium Battery Welding Machine | High-Precision, Fast, SafeNewsNov.17,2025

-

Aluminium Guide Roller | Anodized, Lightweight, Low-NoiseNewsNov.17,2025

-

Tofu Cat Litter Bulk – Eco, Low-Dust, Fast Clumping SupplyNewsNov.17,2025

-

Equipment for Lithium Cell Assembly | Automated & PreciseNewsNov.10,2025

-

Square File Tool – Precision Cut, Hardened Steel, VersatileNewsNov.10,2025

-

Lithium Ion Battery Assembly Machine | Automated, High-SpeedNewsNov.10,2025