car door rubber seal maintenance factory

The Importance of Car Door Rubber Seal Maintenance in Automotive Factories

When it comes to automotive manufacturing, attention to detail is critical in ensuring the longevity and efficiency of the vehicle. One often overlooked yet vital component of vehicle design and function is the rubber seal around the car doors. These seals are crucial for maintaining insulation, enhancing aesthetic appeal, and ensuring safety. A well-maintained door rubber seal can significantly influence vehicle performance and comfort, making it essential for automotive factories to prioritize their maintenance.

Understanding Car Door Rubber Seals

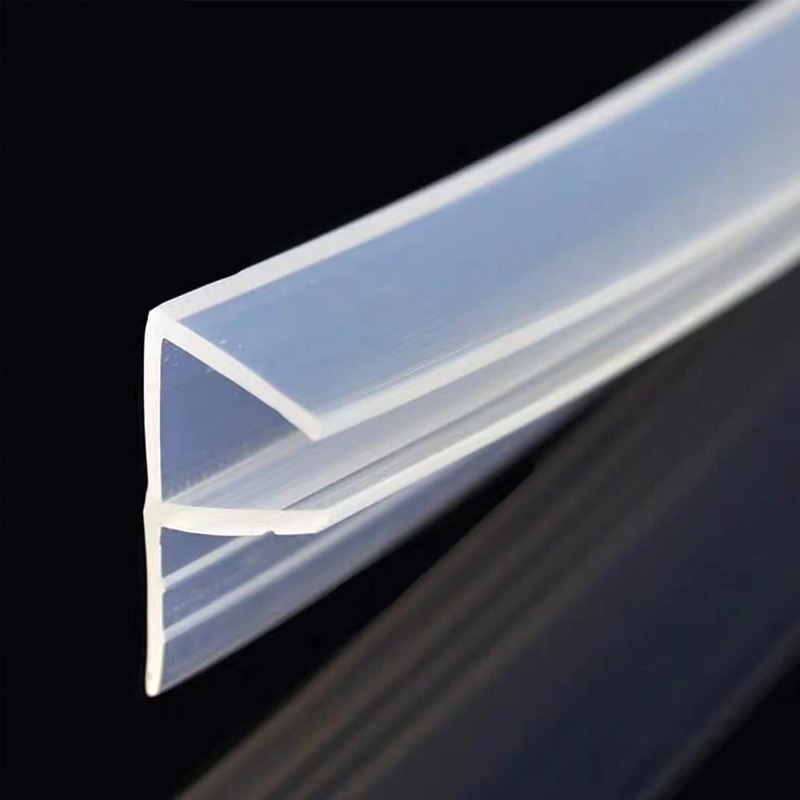

Car door rubber seals, commonly referred to as weather stripping, are designed to prevent air, water, and noise from entering the vehicle. Located around the perimeter of car doors, these seals also play a pivotal role in reducing vibrations and ensuring that the vehicle's body remains secure. Over time, however, these rubber seals can become worn, cracked, or degraded due to exposure to environmental factors such as UV rays, temperature fluctuations, and moisture. Regular maintenance of these seals is needed to extend their lifespan and guarantee functionality.

The Manufacturing Process and Quality Control

In automotive factories, the production of rubber seals involves rigorous quality control measures. High-quality materials are essential; thus, manufacturers often specify certain standards for the rubber used in seals. Natural or synthetic rubber is treated with additives to enhance durability and flexibility. The process typically includes mixing raw materials, molding the rubber into specific shapes, and curing it to ensure it maintains its form under varying conditions.

During the manufacturing process, every batch is subjected to stringent testing. This includes assessments of tensile strength, elongation, and compression set to ensure the seals can withstand the stress they will encounter throughout the vehicle's life. Proper inspection is vital, as even the smallest defects in the sealing can lead to significant issues once the vehicle is in operation.

Maintenance Practices in Automotive Factories

car door rubber seal maintenance factory

Once the rubber seals are installed, the focus shifts to maintenance to ensure longevity. Automotive factories implement several best practices aimed at prolonging the life of these seals

1. Regular Inspection A routine inspection schedule should be established so that any signs of wear, such as cracks or brittleness, can be identified early. Inspectors should check for proper seating and alignment of the seals to ensure they are functioning optimally.

2. Cleaning Dirt and grime can build up on rubber seals, leading to accelerated deterioration. Factories should establish a cleaning protocol using non-abrasive cleaning agents to maintain the integrity of the rubber.

3. Lubrication Applying rubber conditioners or silicone sprays helps to maintain the elasticity of the seals. This treatment prevents them from drying out and cracking, ultimately extending their lifespan.

4. Replacement Protocols Even with proper maintenance, rubber seals will eventually need to be replaced. Factories should have clear guidelines for when and how to replace seals, minimizing downtime in the production process.

The Impact of Proper Maintenance

Proper maintenance of car door rubber seals has far-reaching impacts not only on the vehicle’s performance but also on customer satisfaction and safety. A well-maintained seal ensures reduced noise levels and improved temperature control, leading to a more comfortable driving experience. Moreover, it enhances the vehicle's appearance by preventing unsightly gaps and ensuring the doors close seamlessly.

In conclusion, the maintenance of car door rubber seals is a crucial aspect of automotive manufacturing. By prioritizing inspections, cleanliness, lubrication, and timely replacements, automotive factories can ensure that their vehicles meet high standards of quality and performance. This attention to detail not only enhances the durability of the product but also fosters customer loyalty and satisfaction in a competitive market. With ongoing advancements in materials and maintenance practices, the future of rubber seal technology in automobiles looks promising, paving the way for even more efficient and comfortable vehicles.

Share

-

The Best Lubricants for Aluminum Roller GuidesNewsJul.23,2025

-

Slitting Machine Applications in the Packaging IndustryNewsJul.23,2025

-

Rolling Roller Balancing Techniques for Smooth OperationNewsJul.23,2025

-

How To Optimize An EV Battery Assembly LineNewsJul.23,2025

-

Energy Efficiency in Modern Battery Formation EquipmentNewsJul.23,2025

-

Automation Trends in Pouch Cell Assembly EquipmentNewsJul.23,2025