Lithium Battery Welding Ensures Secure Cell Connections

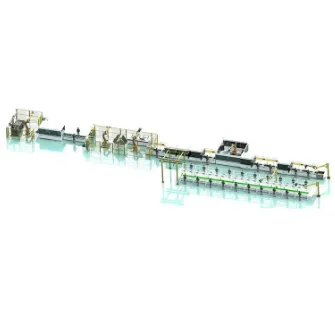

In the ever - evolving lithium battery manufacturing industry, the quality of cell connections is the cornerstone of battery performance, safety, and longevity. Xingtai Shuoding Trading Co., Ltd., a leading name among battery assembly line manufacturers, offers state - of - the - art lithium battery welding machine solutions. Our products are engineered with precision and innovation, ensuring that every cell connection is secure, reliable, and up to the highest industry standards. With a commitment to excellence, we provide comprehensive solutions that empower manufacturers to enhance their production efficiency and product quality.

Xingtai Shuoding Trading Co., Ltd.’s Expertise in Lithium Battery Welding Machines

Xingtai Shuoding Trading Co., Ltd. has established a strong reputation for its proficiency in manufacturing lithium battery welding machine. Our welding machines are designed using advanced technology and high - quality materials, guaranteeing precise and consistent welds. We understand that the stability of cell connections directly impacts the overall performance of lithium batteries. Therefore, our lithium battery welding machine models are equipped with intelligent control systems that adjust welding parameters in real - time, ensuring optimal results in every welding process. This expertise makes us a trusted partner for manufacturers seeking reliable welding solutions.

The Role of Lithium Ion Battery Assembly Machines in Secure Welding

- দ্য lithium ion battery assembly machinefrom Xingtai Shuoding Trading Co., Ltd. plays a critical role in ensuring secure cell connections.

- These assembly machines are designed to seamlessly integrate with lithium battery welding machine systems, creating a streamlined production process.

- They feature precise positioning mechanisms that accurately place battery cells and components, ensuring the welding process is carried out with utmost accuracy.

- The automated nature of our lithium ion battery assembly machine reduces human error and enhances production efficiency.

- Most importantly, it ensures each cell connection is secure and meets the stringent quality requirements of the lithium battery industry.

Advanced Technologies Integrated in Lithium Battery Welding Machines

- Our lithium battery welding machineis equipped with a range of advanced technologies to ensure high-quality and secure welding.

- Laser welding technology, a key feature in many of our models, provides clean, precise, non-contact welding that minimizes the risk of damage to battery cells.

- Ultrasonic welding technology is also available for certain applications, offering excellent weld strength and reliability.

- Additionally, our welding machines integrate monitoring and feedback systems that continuously assess welding quality, making real-time adjustments to ensure each weld meets the highest standards.

- These advanced technologies distinguish our lithium battery welding machinein the market.

Quality Assurance in Lithium Ion Battery Assembly Machines and Lines

Xingtai Shuoding Trading Co., Ltd. places a strong emphasis on quality assurance for our lithium ion battery assembly machine and battery assembly lines. Every machine and line component undergoes rigorous testing and inspection before leaving our factory. We adhere to international quality standards and use high - grade materials in production. For our lithium ion battery assembly machine, we conduct multiple rounds of performance testing to ensure its stability and accuracy. In the case of battery assembly lines, we simulate real - world production scenarios to verify that the entire system, including lithium battery welding machine, functions flawlessly and consistently delivers secure cell connections.

Lithium Battery Welding Machine FAQS

How does our lithium battery welding machine ensure consistent weld quality?

Xingtai Shuoding Trading Co., Ltd.’s lithium battery welding machine ensures consistent weld quality through advanced control systems and high - precision components. Our machines are equipped with intelligent algorithms that adjust welding parameters such as power, time, and pressure according to the specific requirements of different battery cells. The use of high - quality welding heads and sensors further enhances accuracy, enabling the machine to deliver consistent, high - quality welds in every production cycle.

Can our lithium ion battery assembly machine be adapted to different battery sizes?

Yes, our lithium ion battery assembly machine is highly adaptable to different battery sizes. We design our machines with modular structures and adjustable components, allowing for easy reconfiguration. Whether it's small cylindrical cells or large prismatic battery modules, our assembly machines can be quickly adjusted to accommodate various sizes. This flexibility ensures that our clients can use the same machine for different product lines, reducing production costs and increasing efficiency.

What after - sales services do we offer as battery assembly line manufacturers?

As battery assembly line manufacturers, we provide comprehensive after - sales services. Our services include installation and commissioning support to ensure the smooth start - up of the assembly line. We also offer regular maintenance and repair services to keep the line running at peak performance. Additionally, our technical team provides training to client - side operators, ensuring they can use and maintain our lithium battery welding machine effectively. We are committed to long - term support for our clients' production operations.

How do lithium battery welding machines ensure safety during production?

Safety is a top priority in our battery assembly lines. We integrate various safety features, such as emergency stop buttons, safety interlocks, and protective enclosures around lithium battery welding machine and other potentially hazardous equipment. Our assembly lines also comply with international safety standards and regulations. In addition, we provide safety training to operators to ensure they are aware of potential risks and how to operate the equipment safely, minimizing the chances of accidents during the production process.

Can we provide customized lithium battery welding machines for specific production requirements?

Absolutely. As experienced battery assembly line manufacturers, we specialize in providing customized solutions. Our team works closely with clients to understand their specific production requirements, including production capacity, product types, and quality standards. We then design and build assembly lines that integrate lithium battery welding machine in a way that meets these unique needs, ensuring optimal production efficiency and product quality for our clients.

শেয়ার করুন

-

Lithium Battery Welding Machine | High-Precision, Fast, SafeখবরNov.17,2025

-

Aluminium Guide Roller | Anodized, Lightweight, Low-NoiseখবরNov.17,2025

-

Tofu Cat Litter Bulk – Eco, Low-Dust, Fast Clumping SupplyখবরNov.17,2025

-

Equipment for Lithium Cell Assembly | Automated & PreciseখবরNov.10,2025

-

Square File Tool – Precision Cut, Hardened Steel, VersatileখবরNov.10,2025

-

Lithium Ion Battery Assembly Machine | Automated, High-SpeedখবরNov.10,2025