Lithium battery dry electrode process

The performance and cost of lithium batteries depend largely on the manufacturing process of their electrodes. Although the traditional wet coating process has made great progress in the past few decades, its limitations have gradually emerged in the face of the increasing requirements of energy density and production costs. As an emerging manufacturing technology, the dry electrode process has gradually become a new direction for the development of the lithium battery industry with its efficient production process and significant cost savings.

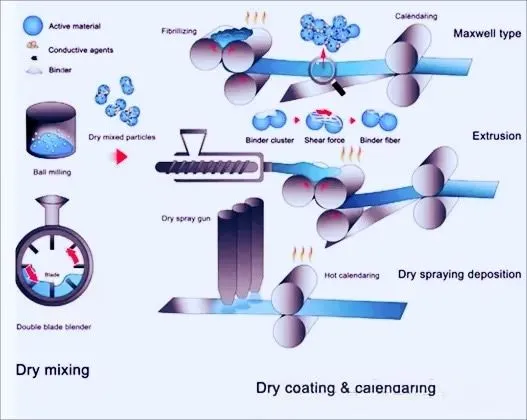

The dry electrode process is a manufacturing process that forms an electrode by dry mixing binders, active materials and conductive agents without using solvents, and then pressing them on the current collector.

Main process flow: 1. Dry mixing: dry mixing the active material, conductive agent and binder in a certain proportion. 2. Calendering: forming a self-supporting film under the action of binder fibrillation, and then covering the surface of the current collector by rolling. 3. Attachment: attach the formed electrode film directly to the current collector.

Key technical features: 1. Binder fibrillation: through a specific process, the binder (such as PTFE) is formed into a microfiber structure to enhance the bonding force with other components. 2. Calendering technology: Multi-roll calendering technology is used to ensure the density and uniformity of the electrode sheet.

Advantages of dry electrode process:

1. Reduced production cost

2. Environmentally friendly

3. High production efficiency

4. Improved battery performance

Dry electrode process has gradually become a new direction for the development of lithium battery industry due to its efficient production process, significant cost savings and excellent battery performance. It not only simplifies the cumbersome steps of traditional wet process, but also performs well in environmental protection and large-scale production. With the continuous advancement of technology and the promotion of industrialization, dry electrode process will surely occupy an important position in future battery manufacturing and promote the new energy industry to a new peak.

Compartir

-

Lithium Battery Welding Machine | High-Precision, Fast, SafeNotíciesNov.17,2025

-

Aluminium Guide Roller | Anodized, Lightweight, Low-NoiseNotíciesNov.17,2025

-

Tofu Cat Litter Bulk – Eco, Low-Dust, Fast Clumping SupplyNotíciesNov.17,2025

-

Equipment for Lithium Cell Assembly | Automated & PreciseNotíciesNov.10,2025

-

Square File Tool – Precision Cut, Hardened Steel, VersatileNotíciesNov.10,2025

-

Lithium Ion Battery Assembly Machine | Automated, High-SpeedNotíciesNov.10,2025