Door Frame Seal Rubber | Weatherproof, Durable, Easy Install

On a rainy audit day in Hebei, I watched a line extrude a quiet hero of the sealing world: the door frame seal rubber. Not flashy, but when it’s wrong you hear wind whistle, see heat leak, and feel the bill for wasted energy. When it’s right, silence. Comfort. Compliance. And margins that don’t evaporate.

Industry snapshot

Demand for door frame seal rubber is moving on two rails: EV/automotive NVH upgrades and building retrofits for energy efficiency. Ozone-resistant EPDM still dominates, but I’m seeing more NBR+PVC for oil exposure and hybrid recipes (EPDM+FIBER+EPDM) to stabilize compression set in hot climates. Compliance-wise, EN 12365 for windows/doors and the usual ASTM D2000/SAE J200 for elastomer classification lead the spec sheets.

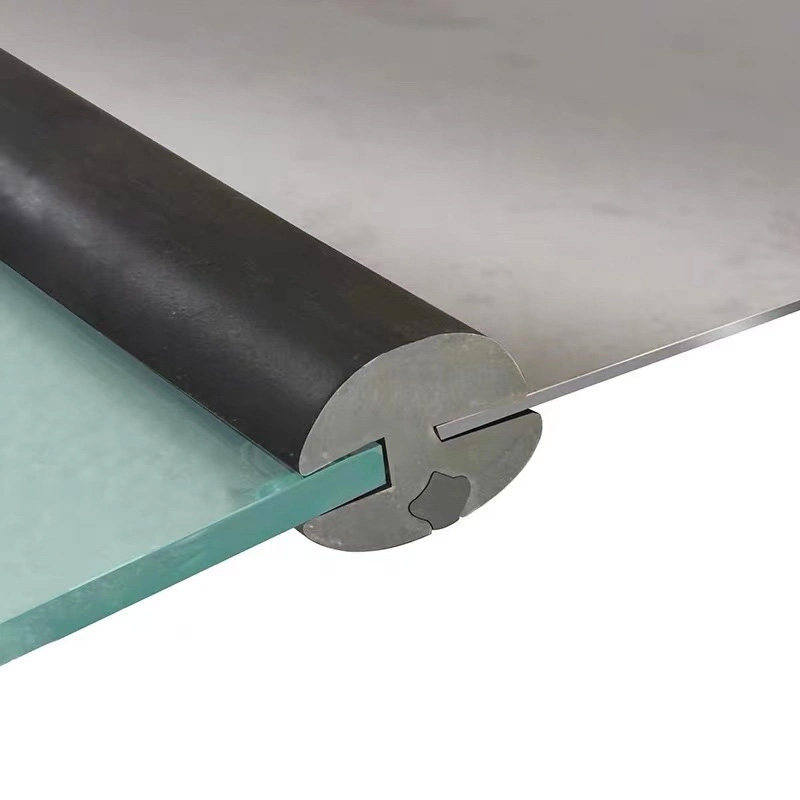

Product at a glance: Windshield rubber sealing strip (SD-001)

Origin: Room 1410, No. 119 Zhongxing East Street, Xiangdu District, Xingtai City, Hebei Province, China. Materials on tap include NBR, EPDM, CR, FKM/ECO blends, and all foam rubber variants. Honestly, it’s a broad menu—good for matching real-world environments rather than forcing a one-compound-fits-all gamble.

| Spec (SD-001) | Typical value (≈) |

|---|---|

| Material family | EPDM/NBR/CR; FKM/ECO blends; solid or foam |

| Hardness | 55–75 Shore A (solid); 10–25 Shore 00 (foam) |

| Temp range | -40 to +120°C (EPDM), up to 150°C (FKM/ECO) |

| Compression set | ≤25% @70°C/22h (ASTM D395, typical) |

| Ozone/UV | No cracks @50 pphm, 40°C, 72h (EPDM) |

| Flame rating (option) | UL 94 V-0 or FMVSS 302 (on request) |

| Profiles | U, P, D, bulb, lip, co-extruded carrier |

| Color/finish | Black matte standard; custom on request |

Where it’s used

- Automotive: door frames, liftgates, windshields, sunroofs (NVH + water sealing)

- Building: exterior doors, clean rooms, cold-room doors

- Rail, marine, and machinery hatches

Many customers say the switch to foam/solid co-extrusions cut cabin noise by a “noticeable notch,” which, yes, is unscientific—but you hear it.

Process flow (how it’s made)

- Compounding: polymer + fillers + anti-ozonants (ASTM D2000 grade targeting).

- Extrusion: precision die for the door frame seal rubber profile.

- Continuous vulcanization: microwave/hot-air or salt-bath; foam cells tuned by blowing agent.

- Co-extrusion: fiber/metal carrier or dual-durometer bulb + lip.

- Post-curing and cut-to-length; PSA or flocking as needed.

- Testing: hardness (ASTM D2240), compression set (ASTM D395), weathering (ISO 4892), water spray, EN 12365 classification, salt fog for carriers (ASTM B117).

Service life: around 8–15 years in typical UV/ozone exposure; real-world use may vary with heat soak and door slam counts, obviously.

Vendor comparison (condensed)

| Supplier | Certs/Standards | MOQ/Lead | Notes |

|---|---|---|---|

| Shuoding (Hebei) | ASTM D2000, EN 12365, ISO 9001/IATF 16949 (typical), RoHS/REACH | ≈3–4 weeks; tooling ≈10–15 days | Broad compounds; co-extrusion; consistent foam cells |

| Regional Vendor B | ASTM D2000; basic RoHS | ≈5–6 weeks | Lower tooling cost; fewer flame-retardant options |

| Low-cost Vendor C | Limited declarations | Variable | Watch compression set and adhesive peel strength |

Customization and real-world feedback

- Profiles: bulb height ±0.2 mm, lip geometry tuned for latch force.

- Adhesives: 3M PSA or heat-activated; flocking for glass run channels.

- Compounds: EPDM+fiber for hot climates; FKM/ECO for chemical splash zones.

Customer notes: “Slam effort dropped ~12% after switching to dual-durometer,” one OEM told me. Another said water ingress claims fell below 0.3% in rainy regions—small number, big savings.

Mini case studies

- EV door program: co-extruded EPDM bulb + flocked lip cut cabin noise ≈1.8 dB(A) at 100 km/h.

- Cold-room doors: foam EPDM with low-temp plasticizer kept rebound at -30°C; leaks down ~22%.

- Marine hatch seals: CR compound with UV stabilizers passed 1,000 h ISO 4892 without chalking.

Compliance and documentation available on request: ISO 9001/IATF 16949, RoHS/REACH, UL 94 options. To be honest, the paperwork matters as much as the polymer these days.

References

- ASTM D2000 / SAE J200: Classification System for Rubber Products

- EN 12365: Building hardware – Gaskets and weatherstripping for doors, windows

- UL 94: Tests for Flammability of Plastic Materials

- ISO 4892: Plastics – Methods of exposure to laboratory light sources

- IATF 16949: Automotive Quality Management System

- RoHS Directive 2011/65/EU and EU REACH Regulation (EC) No 1907/2006

Share

-

Lithium Battery Welding Machine | High-Precision, Fast, SafeNewsNov.17,2025

-

Aluminium Guide Roller | Anodized, Lightweight, Low-NoiseNewsNov.17,2025

-

Tofu Cat Litter Bulk – Eco, Low-Dust, Fast Clumping SupplyNewsNov.17,2025

-

Equipment for Lithium Cell Assembly | Automated & PreciseNewsNov.10,2025

-

Square File Tool – Precision Cut, Hardened Steel, VersatileNewsNov.10,2025

-

Lithium Ion Battery Assembly Machine | Automated, High-SpeedNewsNov.10,2025