Efficient Production Techniques for Battery Assembly Processes in Modern Manufacturing

The Evolution and Impact of Battery Assembly Lines

In an era marked by rapid advancements in technology and the growing demand for sustainable energy solutions, battery assembly lines have emerged as a critical component in various sectors, including electric vehicles (EVs), renewable energy storage, and portable electronics. The efficiency, precision, and scalability of these assembly lines have made them indispensable for meeting the global push towards electrification and eco-friendly practices.

The Importance of Battery Assembly Lines

Battery assembly lines are specifically designed to manufacture battery packs, which are essential for the operation of electric vehicles, smartphones, laptops, and more. As the demand for electric vehicles surges, so does the need for efficient battery production. The automotive industry is transitioning from traditional combustion engines to electric drivetrains, prompting manufacturers to invest heavily in battery technology. A well-optimized assembly line can considerably enhance production rates, minimize costs, and ensure high-quality output, ultimately leading to more competitive and environmentally friendly products.

Cutting-Edge Technologies

Modern battery assembly lines leverage cutting-edge technologies to automate processes, improve accuracy, and reduce waste. The integration of robotics, artificial intelligence (AI), and Internet of Things (IoT) technology has revolutionized battery production. Robots can be programmed to perform repetitive tasks with unwavering precision, such as cell stacking, welding, and packaging. This not only speeds up the manufacturing process but also decreases the likelihood of human error, resulting in higher quality batteries.

AI algorithms analyze production data in real-time, allowing manufacturers to optimize workflows and predict maintenance needs. This predictive maintenance reduces downtime and enhances the overall efficiency of the assembly line. Furthermore, IoT devices monitor energy consumption and environmental conditions within the factory, ensuring that production is as sustainable as possible.

Modules and Packaging

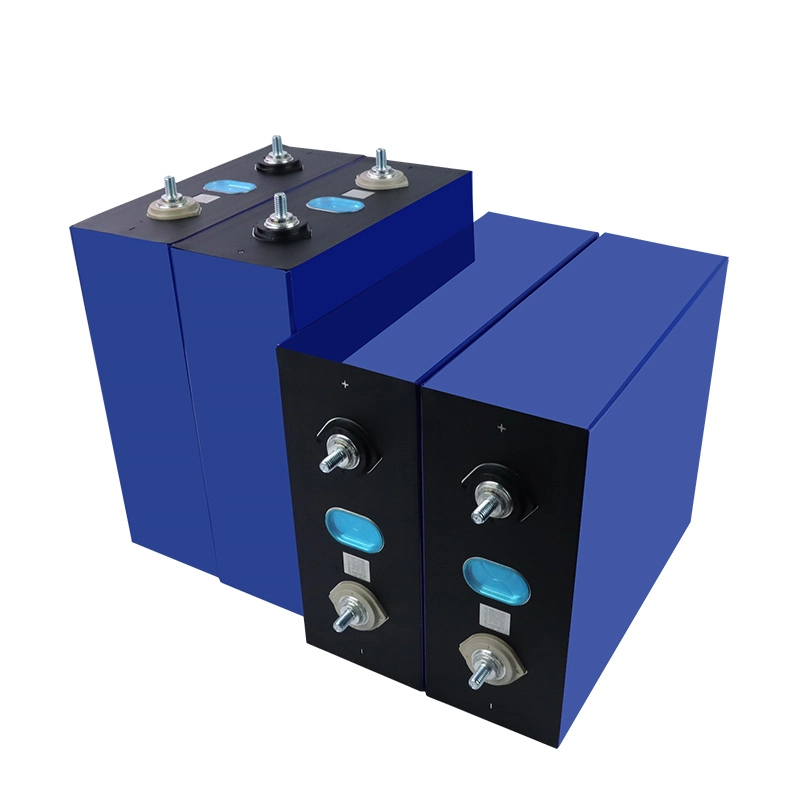

battery assembly line

Battery assembly lines typically operate by first manufacturing individual cells, which are then assembled into larger modules and ultimately integrated into battery packs. Each stage requires meticulous handling and precision engineering to ensure that the end product meets safety and performance standards. For example, battery cells must be carefully tested for capacity, voltage, and safety metrics before they are packaged together.

The design of battery packaging is also a critical element. It must not only protect the cells from physical damage but also manage thermal issues effectively, especially given the intense energy demands of applications like electric vehicles. Advanced cooling systems and thermal management layers are often integrated into the packaging to ensure optimal performance and longevity.

Challenges in Battery Production

While advancements in battery assembly lines present numerous benefits, there are also notable challenges. One significant hurdle is the sourcing of raw materials such as lithium, cobalt, and nickel. The extraction of these minerals can have profound environmental and ethical implications, leading to increased scrutiny from consumers and regulators alike. As a result, many manufacturers are exploring alternative chemistries and recycling methods to minimize their dependence on these materials.

Moreover, the rapid growth of the EV market means that manufacturers must be agile and responsive to fluctuating demand. This necessitates scaling production capabilities quickly, which can strain existing infrastructure if not managed properly.

The Future of Battery Assembly Lines

Looking ahead, the evolution of battery assembly lines will likely be driven by ongoing innovations in technology and a greater emphasis on sustainability. The shift towards solid-state batteries, for instance, holds the promise of providing higher energy density and improved safety. As research and development in this area progress, adjustments to assembly line processes will be essential.

In summary, battery assembly lines are at the nexus of technological advancement and the push for sustainable energy solutions. As industries evolve, the methods and technologies used in battery assembly will continue to adapt, ensuring that we can meet the energy demands of the future while minimizing our environmental footprint. The journey is one of both challenge and opportunity, paving the way for a cleaner, greener, and more electrified world.

Share

-

The Versatility of Jute FabricNewsJun.12,2025

-

The Growing Appeal of Jute ProductsNewsJun.12,2025

-

The Future of Dog NutritionNewsJun.12,2025

-

Revolutionizing Cat Care with Innovative ProductsNewsJun.12,2025

-

Essential Files for Metalworking and Knife MakingNewsJun.12,2025

-

Eco-Friendly Cat Litter RevolutionNewsJun.12,2025