battery assembly line supplier

Battery Assembly Line Supplier Revolutionizing Energy Production

In today's fast-paced world, the demand for efficient energy storage solutions has never been greater. As electric vehicles (EVs), renewable energy systems, and portable electronic devices continue to proliferate, the need for advanced battery technology becomes increasingly crucial. At the heart of this technological advancement is the battery assembly line, a crucial component in the mass production of batteries. A key player in this rapidly evolving market is the battery assembly line supplier, a specialized entity that provides the necessary equipment, technology, and expertise to ensure seamless battery production processes.

The Importance of Battery Assembly Lines

Battery assembly lines are intricate systems designed to manufacture various types of batteries, including lithium-ion, nickel-cadmium, and lead-acid batteries. These lines incorporate advanced automation, robotics, and AI technologies to streamline production, enhance safety, and improve quality control. Efficient battery assembly lines can significantly reduce production costs and time, enabling manufacturers to meet the growing market demand for batteries.

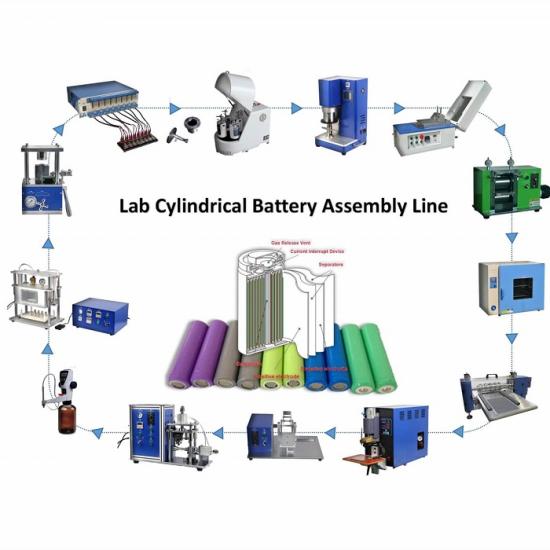

The main components of a battery assembly line include material handling systems, assembly stations, quality inspection units, and packaging lines. Each of these components plays a vital role in ensuring that batteries are produced to the highest standards, with minimal waste and maximal efficiency.

Role of Battery Assembly Line Suppliers

Battery assembly line suppliers are instrumental in the success of battery manufacturers. They provide a comprehensive suite of services, including

1. Design and Engineering Suppliers work closely with manufacturers to design tailored assembly lines that meet specific production requirements. This process includes selecting the right equipment, layout design, and workflow optimization.

2. Automation Solutions The integration of automation technologies, such as robotics, conveyor systems, and machine learning algorithms, is essential for modern battery production. Suppliers develop automated solutions that minimize human intervention, enhance safety, and improve production speeds.

3. Quality Control Systems Ensuring the safety and reliability of battery products is paramount. Suppliers implement advanced quality control systems that utilize sensors and AI to monitor production processes in real-time, identifying defects before the batteries reach consumers.

battery assembly line supplier

4. After-Sales Support and Maintenance The relationship between suppliers and manufacturers does not end with the installation of the assembly line. Ongoing support, maintenance, and training are crucial for optimizing production efficiency and addressing any technical issues that may arise.

5. Research and Development As battery technology evolves, suppliers are often at the forefront of research and development. They invest in new technologies and materials, enabling manufacturers to stay competitive in a rapidly changing market.

Trends in Battery Assembly Line Technology

The industry is witnessing several trends that are reshaping the landscape of battery assembly line suppliers

- Sustainability With increasing awareness of environmental issues, the focus on sustainable production practices is paramount. Suppliers are incorporating eco-friendly materials and energy-efficient processes in the design of assembly lines.

- Modular Design Suppliers are offering modular assembly line solutions that allow manufacturers to scale production up or down based on market demand. This flexibility is essential for adapting to the fluctuating energy market.

- Digital Transformation The rise of Industry 4.0 has led to increased connectivity and data utilization in battery manufacturing. Suppliers are leveraging IoT technologies to facilitate real-time monitoring and data analytics, improving production efficiency.

- Collaboration and Partnerships As the battery industry becomes more competitive, collaboration between suppliers and manufacturers is essential. Partnerships can lead to innovations that drive down costs and improve product quality.

Conclusion

In summary, battery assembly line suppliers are vital to the continued growth and innovation within the energy storage sector. Their expertise in design, automation, quality control, and ongoing support ensures that battery manufacturers can produce high-quality products efficiently and sustainably. As the world transitions towards greener energy solutions, the role of battery assembly line suppliers will only grow in importance, driving advancements that will shape the future of energy storage and consumption. By investing in sophisticated assembly line technologies, suppliers are not only enhancing production capabilities but also contributing to a more sustainable and energy-efficient world.

Share

-

The Diverse Application Scenarios of Flat FilesNewsJul.21,2025

-

Stainless Steel Hand File: The Backbone of Metal ProcessingNewsJul.21,2025

-

Stainless Steel File: A Precision Tool for Industrial and Manual FieldsNewsJul.21,2025

-

Flat File: A Powerful Assistant for Metal and Wood ProcessingNewsJul.21,2025

-

Diversified Application Scenarios of Stainless Steel Hand FilesNewsJul.21,2025

-

Diamond Steel File for Hardened Steel: A Precision Machining ToolNewsJul.21,2025