Rubber Strips for Door Glass Water Barrier Custom Manufacturing Solutions

The Evolution and Importance of Door Glass Water Blocking Rubber Strips in Factories

In modern industrial operations, ensuring that facilities remain safe, effective, and efficient is paramount. One often-overlooked yet crucial component in many factories is the door glass water blocking rubber strip. This simple yet effective accessory plays a significant role in safeguarding products, improving energy efficiency, and ensuring worker safety. Understanding the various functions, materials, and manufacturing processes of these rubber strips provides invaluable insight into their importance in factory settings.

What is a Door Glass Water Blocking Rubber Strip?

A door glass water blocking rubber strip is a flexible, durable strip that is typically applied around the glass sections of doors or windows in industrial environments. Its primary purpose is to create a barrier that prevents water infiltration, especially in areas where external elements can affect the internal environment of a facility. By blocking water, these strips help maintain the integrity of the workspace, protecting machinery, inventory, and sensitive equipment from moisture damage.

The Importance of Water Blocking Rubber Strips

1. Protection Against Water Damage Many factories deal with liquids, whether from manufacturing processes or occasional spills. Water blocking rubber strips act as a barrier, mitigating the risks associated with water exposure. This is particularly important for businesses dealing in electronics, pharmaceuticals, or food production, where moisture can lead to significant losses.

2. Energy Efficiency Maintaining a stable internal environment is crucial for energy efficiency. Water blocking rubber strips assist in insulating the interior spaces from external weather conditions. During hot or cold seasons, they help regulate the temperature inside a facility, allowing for more efficient heating and cooling, thus reducing energy costs.

3. Safety Enhancement Slip and fall accidents in factories are a leading cause of workplace injuries. By preventing water from entering work areas, water blocking rubber strips reduce the likelihood of slick floors. This contributes to a safer working environment, protecting employees and minimizing the potential for costly accidents.

4. Aesthetic Appeal In addition to functional benefits, water blocking rubber strips can also enhance the visual appeal of a facility. They come in various designs, colors, and textures that can complement the factory's overall design, promoting a professional image.

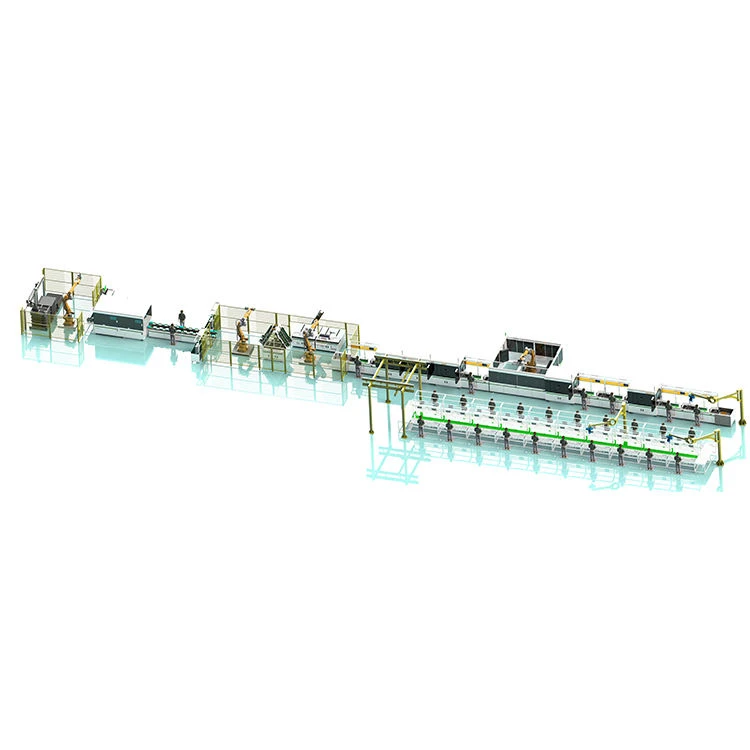

door glass water blocking rubber strip factories

Manufacturing of Rubber Strips

The production of door glass water blocking rubber strips involves several key stages. Factories dedicated to this process typically use rubber polymers, which can be synthetic or natural. Each type of rubber offers different levels of durability, flexibility, and resistance to environmental factors.

1. Material Selection The choice of rubber is crucial. For water blocking applications, manufacturers often opt for high-quality EPDM (Ethylene Propylene Diene Monomer) rubber. This type of rubber is known for its excellent weather resistance, UV stability, and prolonged lifespan, making it ideal for industrial use.

2. Molding Process Once the rubber is selected, it's molded into specified shapes and sizes. Advanced molding techniques allow for the production of rubber strips that fit various door and glass configurations, ensuring an airtight seal against water ingress.

3. Quality Control After production, rubber strips undergo rigorous quality control tests. These checks ensure that the strips meet industry standards for durability, flexibility, and water resistance. Factories may subject the strips to various environmental tests to simulate real-world conditions.

4. Customization Many factories offer customization options, allowing clients to specify the exact dimensions and characteristics needed for their specific applications. This level of personalization allows businesses to achieve a perfect fit for their operational needs.

Conclusion

In conclusion, door glass water blocking rubber strips are essential components in the operational efficiency of factories. Their role in preventing water damage, enhancing safety, and promoting energy efficiency cannot be underestimated. As manufacturers continue to innovate and improve the design and materials of these strips, industries can look forward to more effective solutions that not only protect their investments but also contribute to a safer and more sustainable working environment. Investing in high-quality rubber strips is not just a matter of functionality; it is a strategic decision that can impact the overall success of a manufacturing operation.

Share

-

The Best Lubricants for Aluminum Roller GuidesNewsJul.23,2025

-

Slitting Machine Applications in the Packaging IndustryNewsJul.23,2025

-

Rolling Roller Balancing Techniques for Smooth OperationNewsJul.23,2025

-

How To Optimize An EV Battery Assembly LineNewsJul.23,2025

-

Energy Efficiency in Modern Battery Formation EquipmentNewsJul.23,2025

-

Automation Trends in Pouch Cell Assembly EquipmentNewsJul.23,2025