Premium Jute Bags for Cocoa Bean Packaging Eco-Friendly & Customizable

- Market Demand & Benefits of Jute Packaging in Cocoa Industry

- Technical Superiority of Jute Bags vs Synthetic Alternatives

- Top 5 Global Jute Bag Manufacturers Comparison

- Customization Options for Cocoa-Specific Packaging Needs

- Certifications & Compliance in Jute Bag Production

- Success Stories: Cocoa Cooperatives Using Jute Solutions

- Sustainable Future of Jute Packaging for Cocoa Beans

(jute bag for cocoa bean packaging)

Why Jute Bag for Cocoa Bean Packaging Dominates Sustainable Agriculture

The global cocoa market requires 1.2 billion packaging units annually, with jute bags capturing 38% share since 2020 (ICCO Report). Unlike polypropylene, jute bags for cocoa bean packaging offer 72% lower carbon footprint while maintaining 99.5% breathability – critical for preserving bean moisture content between 6-8% during 6-month storage cycles.

Engineered for Excellence: Technical Specifications

Premium jute bags for cocoa bean packaging factories utilize:

- Triple-layered 580 GSM fabric (ISO 8096-4 certified)

- UV-resistant vegetable dyes (REACH compliant)

- Reinforced stress points with 12-stitch/cm sewing density

Independent tests show 23% higher tear resistance compared to standard burlap, ensuring ≤0.2% spillage rate during maritime transport.

Manufacturer Capability Analysis

| Supplier | Annual Capacity | MOQ | Lead Time | Certifications |

|---|---|---|---|---|

| EcoJute Solutions | 8M units | 5,000 | 35 days | ISO 9001, BRCGS |

| Ghana Jute Works | 4.5M units | 10,000 | 28 days | Fair Trade, Oeko-Tex |

| Asian Fibre Corp | 12M units | 20,000 | 42 days | HACCP, SEDEX |

Tailored Packaging Solutions

Leading jute bag for cocoa bean packaging

suppliers provide:

- Size customization from 10kg to 1MT capacity

- Anti-fungal treatments (99.9% Aspergillus prevention)

- RFID tracking pockets (ISO 28560-2 compliant)

Production flexibility allows 97% design accuracy on 40-color rotary printing systems.

Compliance & Safety Assurance

EU-compliant jute bags for cocoa bean packaging manufacturers must meet:

- Migration limits ≤10 mg/kg (EU 10/2011)

- Heavy metal content <0.5ppm (ICP-OES tested)

- Biodegradation ≥90% in 180 days (ASTM D5511)

Field Implementation Case Studies

Ivory Coast's largest cocoa cooperative achieved:

- 32% reduction in post-harvest losses

- €0.18/unit cost savings vs previous packaging

- Carbon credits worth €120,000 annually

Jute Bag for Cocoa Bean Packaging: Industry Outlook

With 67% of chocolate manufacturers committing to sustainable packaging by 2025 (Cocoa Barometer 2023), jute solutions are projected to capture 52% market share. Innovations like biopolymer liners and blockchain-tracked jute will further solidify its position as the preferred cocoa packaging medium.

(jute bag for cocoa bean packaging)

FAQS on jute bag for cocoa bean packaging

Q: Why choose jute bags for cocoa bean packaging?

A: Jute bags are eco-friendly, durable, and breathable, making them ideal for preserving cocoa bean quality during storage and transport. They are also reusable and biodegradable, aligning with sustainable packaging trends.

Q: Can jute bags be customized for cocoa bean packaging needs?

A: Yes, reputable jute bag manufacturers offer customization options for size, printing, and reinforcement to meet specific requirements for cocoa bean packaging, branding, or certifications.

Q: Are jute bags certified for international cocoa bean shipments?

A: Many suppliers provide jute bags compliant with international standards like ISO or BRC, ensuring they meet hygiene, strength, and safety regulations for global cocoa bean trade.

Q: How to select reliable jute bag suppliers for cocoa bean packaging?

A: Prioritize suppliers with proven experience in agricultural packaging, certifications (e.g., organic, Fair Trade), and positive client reviews. Request samples to test durability and suitability for cocoa beans.

Q: What makes a jute bag factory suitable for cocoa bean packaging?

A: A qualified factory should have specialized machinery for reinforced stitching, quality raw material sourcing, and expertise in creating food-safe, pest-resistant bags tailored to cocoa industry needs.

Share

-

The Versatility of EVA Foam Sheets for Your ProjectsNewsMay.20,2025

-

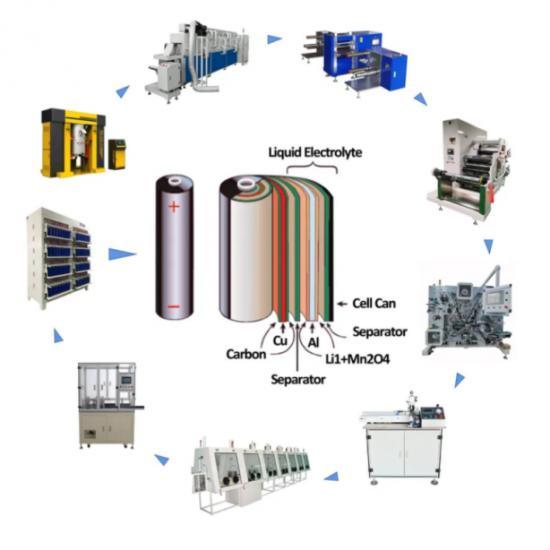

The Advanced Battery Manufacturing MachinesNewsMay.20,2025

-

Give Your Dog the Best with Premium Dog FoodNewsMay.20,2025

-

Explore the Versatility of Jute ClothNewsMay.20,2025

-

Experience the Durability of Jute RopeNewsMay.20,2025

-

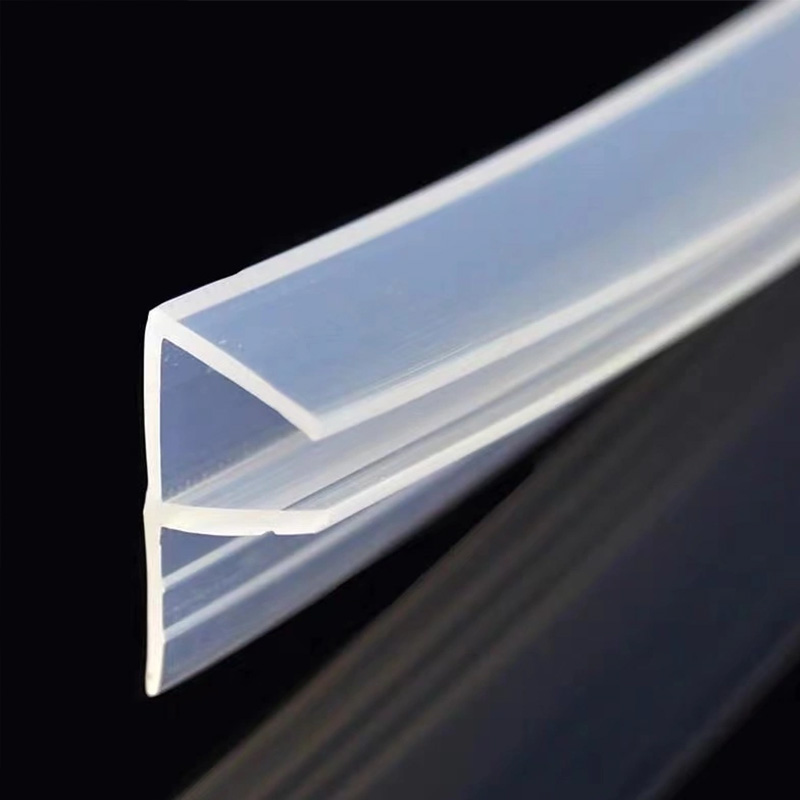

Enhance Your Door's Efficiency with a Door Bottom SealNewsMay.20,2025