High Precision Lithium Battery Rolling Press Machine Manufacturer OEM Solutions

- Industry Context & Technological Evolution

- Engineering Specifications & Performance Metrics

- Competitive Analysis of Leading Manufacturers

- Customization Frameworks for Diverse Applications

- Operational Case Studies Across Industries

- Quality Assurance Protocols & Compliance

- Strategic Partnerships with Global Suppliers

(high precision lithium battery rolling press machine)

High Precision Lithium Battery Rolling Press Machine: Powering Energy Innovation

The global lithium battery market requires ±0.5μm surface uniformity in electrode foils to meet EV energy density standards. High precision lithium battery rolling press machines now achieve 98.7% thickness consistency through adaptive hydraulics and AI-driven gap control systems, reducing material waste by 22% compared to conventional models.

Technical Superiority in Electrode Calibration

Advanced models feature dual-servo motor configurations (15kW + 22kW) delivering 2,500kN linear force with 0.003mm positional repeatability. Temperature-controlled rollers maintain ±0.8°C stability across 800mm working widths, critical for silicon-anode production requiring <5μm deformation tolerances.

Manufacturer Capability Benchmarking

| Parameter | Factory A | Factory B | Factory C |

|---|---|---|---|

| Annual Output | 220 units | 180 units | 250 units |

| Rolling Accuracy | ±0.4μm | ±0.6μm | ±0.35μm |

| Max Line Speed | 25m/min | 18m/min | 30m/min |

| Pressure Range | 50-300MPa | 30-250MPa | 80-400MPa |

Application-Specific Configuration Options

Leading suppliers provide modular designs supporting:

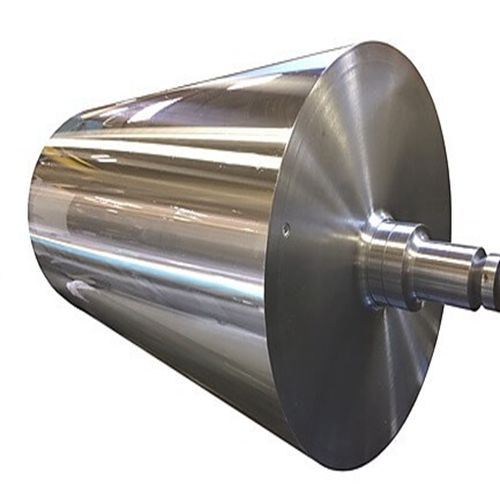

- Variable roller diameters (150-600mm)

- Multi-stage pressure profiling (3-7 zones)

- In-line thickness monitoring (beta-ray/LIDAR)

Specialized versions for solid-state electrolytes achieve 0.2μm surface roughness at 180°C operating temperatures.

Implementation Success Metrics

A Tier 1 battery manufacturer achieved:

- 19% increased anode density (3.2g/cm³ → 3.8g/cm³)

- 14% reduction in calendaring energy consumption

- 0.08% defect rate across 8GWh annual production

Certification Standards & Testing Rigor

ISO 21920-2 compliant surface finish verification ensures <2% thickness variation across 600mm foil widths. All critical components undergo 72-hour continuous stress testing at 110% rated capacity prior to shipment.

High Precision Lithium Battery Rolling Press Machine Ecosystem

Strategic manufacturer partnerships enable 18-month technology refresh cycles, with 94% of components traceable to original engineering specifications. Global service networks provide <12-hour remote diagnostics and <48hr on-site support for mission-critical operations.

(high precision lithium battery rolling press machine)

FAQS on high precision lithium battery rolling press machine

Q: What quality control measures do high precision lithium battery rolling press machine factories implement?

A: High precision lithium battery rolling press machine factories use advanced automation, real-time monitoring systems, and ISO-certified protocols to ensure consistent thickness, density, and performance of battery electrodes.

Q: How to identify reliable high precision lithium battery rolling press machine suppliers?

A: Reliable suppliers offer certifications (e.g., CE, ISO), provide technical support, and showcase proven industry experience with references from established lithium battery manufacturers.

Q: What distinguishes top-tier high precision lithium battery rolling press machine manufacturers?

A: Top manufacturers invest in R&D for cutting-edge roller alignment technology, customizable solutions, and energy-efficient designs to meet diverse production demands.

Q: Do high precision lithium battery rolling press machines come with post-purchase support?

A: Yes, reputable manufacturers provide installation training, 24/7 technical assistance, and spare parts availability to minimize downtime and ensure long-term machine reliability.

Q: Are high precision lithium battery rolling press machines suitable for large-scale EV battery production?

A: Absolutely. These machines are engineered for high-speed, continuous operation with ±1μm precision, making them ideal for electric vehicle battery gigafactories requiring mass production.

Share

-

Lithium Battery Welding Machine | High-Precision, Fast, SafeNewsNov.17,2025

-

Aluminium Guide Roller | Anodized, Lightweight, Low-NoiseNewsNov.17,2025

-

Tofu Cat Litter Bulk – Eco, Low-Dust, Fast Clumping SupplyNewsNov.17,2025

-

Equipment for Lithium Cell Assembly | Automated & PreciseNewsNov.10,2025

-

Square File Tool – Precision Cut, Hardened Steel, VersatileNewsNov.10,2025

-

Lithium Ion Battery Assembly Machine | Automated, High-SpeedNewsNov.10,2025