Automated Lithium Ion Battery Pack Assembly Line Solutions

Lithium ion battery pack assembly line is a key solution in the manufacturing industry, specifically within Special Equipment Manufacturing Industry and Specialized equipment for battery manufacturing. This article explores how XINGTAI SHUODING TRADING CO.,LTD supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Lithium ion battery pack assembly line Overview

- Benefits & Use Cases of equipment for lithium battery assembly in Specialized equipment for battery manufacturing

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on lithium ion battery pack assembly line from XINGTAI SHUODING TRADING CO.,LTD

Lithium ion battery pack assembly line Overview

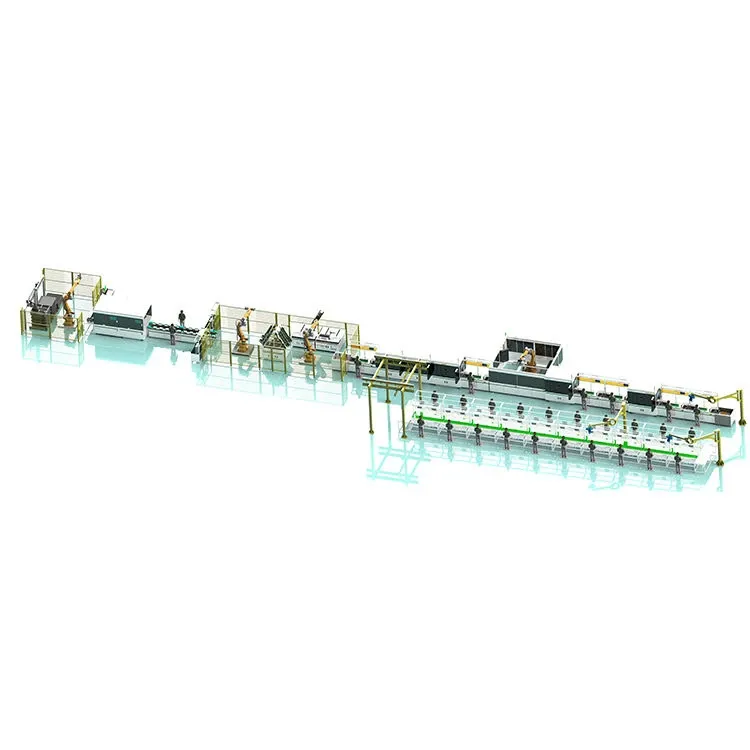

In the dynamic landscape of modern manufacturing, the demand for efficient and precise battery production solutions has never been greater. At the heart of this innovation lies the advanced lithium ion battery pack assembly line, a crucial component for companies operating within the Special Equipment Manufacturing Industry, particularly those focused on Specialized equipment for battery manufacturing. These sophisticated lines are designed to handle everything from individual cell preparation to final module integration, ensuring consistency, reliability, and high throughput.

Modern equipment for lithium battery assembly integrates cutting-edge technologies such as automated welding, precise dispensing, and intelligent quality control systems. For instance, XINGTAI SHUODING TRADING CO.,LTD specializes in providing state-of-the-art industrial and commercial energy storage module laser production lines, which are quintessential examples of advanced lithium ion battery assembly equipment. Our solutions are engineered to meet the rigorous demands of large-scale production, offering robust performance and seamless operation. By leveraging our expertise, businesses can significantly enhance their manufacturing capabilities, producing high-quality battery packs that power everything from electric vehicles to grid-scale energy storage systems.

Benefits & Use Cases of equipment for lithium battery assembly in Specialized equipment for battery manufacturing

The specialized nature of battery production demands equipment that offers unparalleled precision and efficiency. Our equipment for lithium battery assembly provides distinct advantages for businesses in the Specialized equipment for battery manufacturing sector. Key benefits include enhanced automation, which reduces labor costs and human error, leading to higher output and consistent product quality. The integration of advanced laser welding technology, as found in XINGTAI SHUODING TRADING CO.,LTD’s offerings, ensures stronger, more reliable connections within battery packs, crucial for both performance and safety.

Specific use cases for a lithium ion battery pack assembly line are diverse. They include the mass production of battery modules for electric vehicles (EVs), the assembly of large-scale energy storage systems (ESS) for industrial and commercial applications, and even the creation of compact power solutions for portable electronics. Our expertise extends to providing comprehensive lines that manage everything from cell sorting and stacking to module testing and packaging. While historically, the production of lead acid battery production line required different machinery, the modern shift towards lithium-ion batteries means that specialized equipment for lithium cell assembly is now paramount, driving innovation and efficiency in a rapidly expanding market. XINGTAI SHUODING TRADING CO.,LTD is at the forefront, empowering manufacturers with the tools they need to succeed.

Cost, Maintenance & User Experience

Investing in a high-quality lithium ion battery pack assembly line from XINGTAI SHUODING TRADING CO.,LTD represents a strategic decision with significant long-term returns. While the initial capital expenditure for advanced equipment for lithium battery assembly might seem substantial, the total cost of ownership (TCO) is optimized through several factors. Our machinery is built for exceptional durability, utilizing robust components and precision engineering to minimize wear and tear, thereby reducing unexpected downtime and costly repairs. This longevity translates directly into a strong return on investment (ROI) by maximizing production uptime and output efficiency over years of operation.

Maintenance for XINGTAI SHUODING TRADING CO.,LTD’s lithium ion battery assembly equipment is designed to be streamlined and predictive. With intuitive diagnostic systems and readily available technical support, maintenance routines are simplified, ensuring equipment remains in peak condition. User experience is a core focus; our systems feature user-friendly interfaces, ergonomic designs, and automated processes that reduce the learning curve for operators. Feedback from customers in the Special Equipment Manufacturing Industry consistently highlights the ease of operation and the reliability of our lines, noting how the precision and automation of our equipment for lithium cell assembly lead to higher throughput and fewer defects, making operations smoother and more profitable.

Sustainability & Market Trends in manufacturing

The global manufacturing sector is undergoing a profound transformation, driven by an accelerating focus on sustainability, regulatory compliance, and technological advancement. In the realm of battery production, this shift is particularly pronounced. The escalating demand for electric vehicles, renewable energy storage, and portable electronic devices necessitates highly efficient and environmentally responsible manufacturing processes. As a leading provider of lithium ion battery pack assembly line solutions, XINGTAI SHUODING TRADING CO.,LTD is committed to aligning with these crucial market trends.

Our advanced equipment for lithium battery assembly is designed not only for peak performance but also with resource efficiency in mind, minimizing waste and energy consumption. We recognize the importance of robust quality control to ensure battery longevity and reduce the need for replacements, thereby contributing to a circular economy. The market's pivot from traditional power sources, like those supported by legacy lead acid battery production line systems, towards cleaner, more energy-dense lithium-ion technology is a key driver for our innovation. XINGTAI SHUODING TRADING CO.,LTD positions itself as a forward-thinking and eco-conscious partner, providing the lithium ion battery assembly equipment that will enable manufacturers to meet stringent environmental regulations and capitalize on the immense growth opportunities in the sustainable energy sector.

Conclusion on lithium ion battery pack assembly line from XINGTAI SHUODING TRADING CO.,LTD

The evolution of energy storage solutions has placed the lithium ion battery pack assembly line at the forefront of the Special Equipment Manufacturing Industry. From enhancing production efficiency to ensuring product quality and contributing to sustainability, the advanced equipment for lithium battery assembly offered by XINGTAI SHUODING TRADING CO.,LTD is indispensable for B2B decision-makers. Our solutions represent a commitment to durability, performance, and technological leadership, empowering businesses to thrive in the competitive Specialized equipment for battery manufacturing sector.

By choosing XINGTAI SHUODING TRADING CO.,LTD, you are investing in reliable lithium ion battery assembly equipment designed for the future of energy. Our dedication to innovation and customer success makes us the ideal partner for your manufacturing needs, providing the precise equipment for lithium cell assembly that drives progress. Enhance your production capabilities and secure your market position with our cutting-edge technology.

Contact us: email: sdtrading0927@126.com

Visit our website: https://www.xtshuoding.com

Share

-

Lithium Battery Welding Machine | High-Precision, Fast, SafeNewsNov.17,2025

-

Aluminium Guide Roller | Anodized, Lightweight, Low-NoiseNewsNov.17,2025

-

Tofu Cat Litter Bulk – Eco, Low-Dust, Fast Clumping SupplyNewsNov.17,2025

-

Equipment for Lithium Cell Assembly | Automated & PreciseNewsNov.10,2025

-

Square File Tool – Precision Cut, Hardened Steel, VersatileNewsNov.10,2025

-

Lithium Ion Battery Assembly Machine | Automated, High-SpeedNewsNov.10,2025