Creating Efficient Production Strategies for Triangular Files Manufacturing

Triangular Files Factory Precision and Craftsmanship in Tool Manufacturing

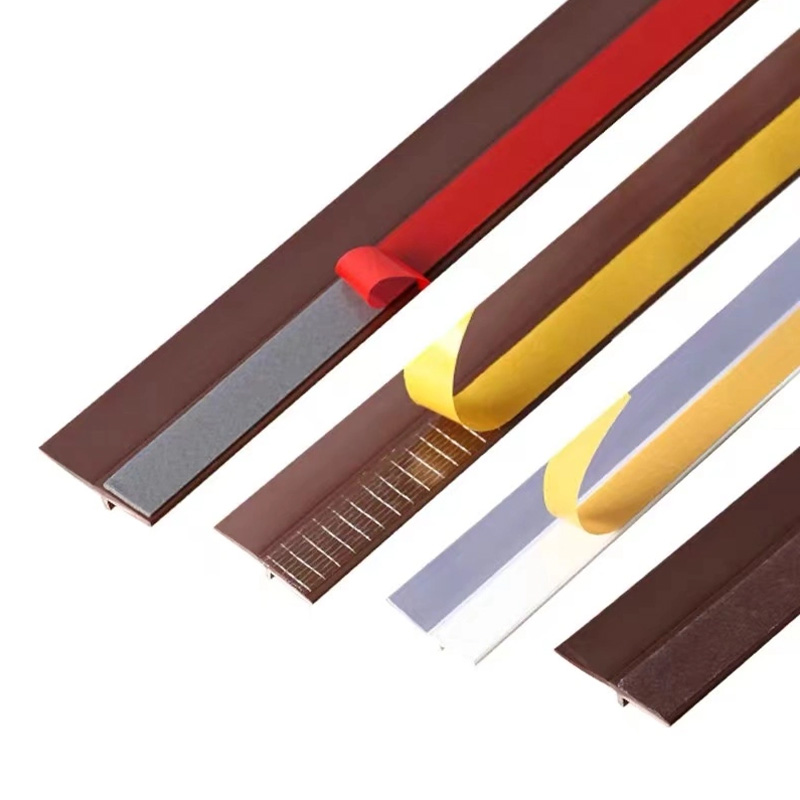

In today's manufacturing landscape, precision tools play a pivotal role in various industries, from automotive to aerospace and woodworking. Among the essential hand tools in the arsenal of craftsmen and engineers are triangular files. These tools, characterized by their unique triangular cross-section, are specifically designed for sharpening, smoothing, and shaping materials, making them crucial for achieving fine finishes and meticulous detailing. The triangular files factory stands at the forefront of this essential manufacturing sector, committed to providing high-quality tools that meet the demands of professionals and hobbyists alike.

The production of triangular files starts with the careful selection of raw materials. High-carbon steel is a common choice due to its superior hardness and the ability to retain sharpness over time. The factory processes these materials using state-of-the-art machinery and techniques, ensuring that each file is crafted with precision. Advanced technologies, including computerized numerical control (CNC) milling, allow for exact specifications to be met while minimizing waste and maximizing efficiency.

Once the raw materials are ready, they undergo a series of manufacturing stages. The first step involves forging the steel into the desired shape. This process not only gives the file its triangular profile but also enhances the durability of the tool. After forging, each file is meticulously heat-treated, a critical stage that strengthens the steel and enhances its performance under stress.

triangular files factory

After heat treatment, the triangular files are meticulously ground and sharpened. This step is crucial, as the teeth of the file must be shaped to perform specific tasks effectively. The factory employs skilled technicians who inspect and adjust each file during this process, ensuring that they meet stringent quality control standards. As a result, every triangular file produced is not only functional but also ergonomically designed for comfort and ease of use.

In addition to standard triangular files, many factories also offer custom solutions tailored to meet the unique needs of their clients. Whether it’s specific dimensions, unique tooth patterns, or branding requirements, the flexibility of modern manufacturing allows for a wide array of customization options.

Sustainability is also a key consideration in the triangular files factory. Many manufacturers are adopting eco-friendly practices, such as recycling scrap materials and reducing energy consumption during production. This commitment to sustainability not only benefits the environment but also appeals to socially conscious consumers who are increasingly looking for responsible businesses.

In conclusion, the triangular files factory exemplifies the intersection of tradition and technology in tool manufacturing. By combining high-quality materials, advanced machinery, and skilled craftsmanship, these factories produce essential tools that empower professionals in their crafts. As the demand for precision tools continues to grow, triangular files remain an indispensable tool in various industries, symbolizing reliability and efficiency.

Share

-

The Ultimate Guide to Square Files for Precision WorkNewsJun.26,2025

-

The Power of Flat FilesNewsJun.26,2025

-

Revolutionize Your Craft with High-Performance Rotary FilesNewsJun.26,2025

-

Precision and Durability with Diamond-Coated Needle FilesNewsJun.26,2025

-

Essential Tools for Precision Work: Round Metal Files and MoreNewsJun.26,2025

-

Essential Tools for Precision Sharpening: Triangular FilesNewsJun.26,2025