Versatile Role of Rubber Sealing Strips in Vehicle Performance

Rubber sealing strips, including extruded rubber sealing strips, flexible rubber sealing strips, and adhesive rubber seal strips, are integral components in modern vehicles. These versatile strips serve critical functions, such as weatherproofing, noise reduction, and vibration damping, enhancing comfort, durability, and performance. This article delves into how these sealing strips contribute to vehicle functionality and driver satisfaction.

Weatherproofing with Rubber Sealing Strips

One of the primary roles of rubber sealing strips in vehicles is to provide weatherproofing, protecting the interior from external elements.

Sealing Against Rain and Moisture:

- Extruded rubber sealing stripsare designed to create tight seals around doors, windows, and sunroofs, preventing water ingress during rain or car washes.

- By blocking moisture, they protect the interior components from corrosion, mold, and electrical damage.

Insulation from Dust and Debris:

- Sealing strips prevent dust, dirt, and other debris from entering the cabin, maintaining a clean and hygienic environment.

- This is particularly beneficial in off-road or desert conditions where airborne particles are prevalent.

Temperature Regulation:

- Flexible rubber sealing stripsensure that temperature-controlled air stays inside the cabin, enhancing the efficiency of heating and cooling systems.

- This reduces energy consumption and improves overall climate comfort for passengers.

The durability and elasticity of these strips make them indispensable for maintaining a weatherproof vehicle interior.

Noise Reduction with Adhesive Rubber Seal Strips

Noise reduction is another key function of adhesive rubber seal strips, contributing to a quieter and more enjoyable driving experience.

Blocking Wind Noise:

- Sealing strips minimize gaps around doors and windows, preventing wind noise from penetrating the cabin, even at high speeds.

- Flexible rubber sealing stripsconform to irregular surfaces, creating seamless seals that effectively reduce turbulence-related noise.

Dampening Road Noise:

- Rubber strips also absorb and block sound from the road, including tire noise and vibrations caused by uneven surfaces.

- This is especially beneficial for long-distance drivers seeking a peaceful journey.

Enhanced Acoustic Performance:

The use of high-quality extruded rubber sealing strips ensures better acoustic insulation, allowing audio systems to perform optimally without interference from external noise.

By improving sound insulation, these strips contribute significantly to passenger comfort and focus while driving.

Vibration Damping with Flexible Rubber Sealing Strips

In addition to weatherproofing and noise reduction, flexible rubber sealing strips play a critical role in damping vibrations and improving vehicle durability.

Reducing Structural Vibration:

- Rubber strips act as cushions between rigid components, such as metal panels, reducing vibrations caused by engine operation, road irregularities, or external impacts.

- This prevents wear and tear on vehicle parts, prolonging their lifespan.

Passenger Comfort:

- By damping vibrations, sealing strips ensure a smoother ride, reducing fatigue for passengers and drivers on bumpy or uneven roads.

Component Protection:

- Adhesive rubber seal stripsprotect sensitive components, such as glass panels or electronic assemblies, from damage caused by vibrations.

- Their elasticity allows them to maintain their function over time, even in extreme conditions.

Vibration damping not only enhances driving comfort but also contributes to the structural integrity and longevity of the vehicle.

Material and Design Innovations in Extruded Rubber Sealing Strips

Modern sealing strips are engineered to meet the diverse needs of vehicle applications, utilizing advanced materials and designs.

Material Choices:

- EPDM Rubber: Known for its excellent resistance to UV, ozone, and temperature extremes, EPDM is a common material for sealing strips in vehicles.

- Silicone Rubber: Offers superior flexibility and thermal stability, making it ideal for high-performance and luxury vehicles.

- PVC and Thermoplastics: Lightweight and cost-effective options for specific applications.

Extruded Designs:

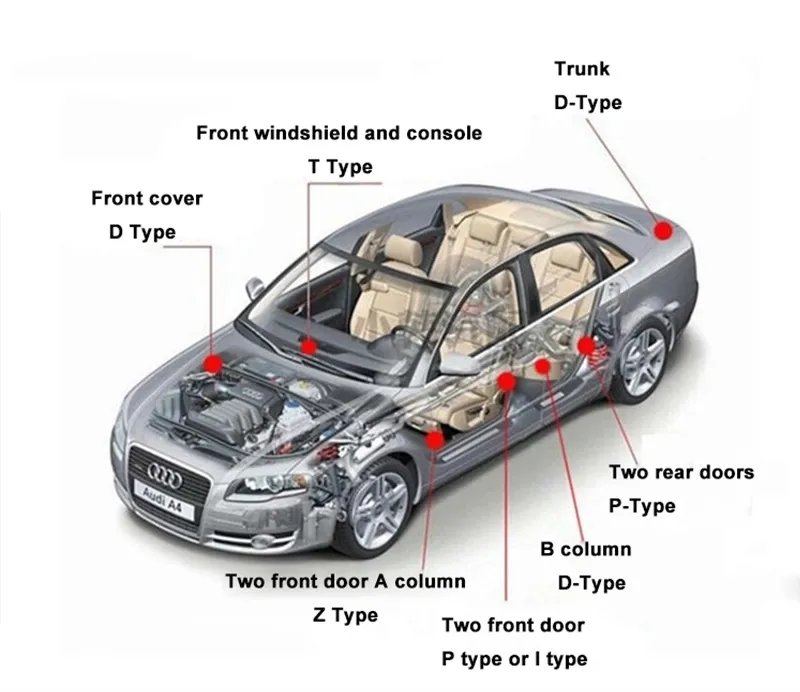

- Extruded rubber sealing stripsare customized to fit complex shapes and contours, ensuring perfect seals in doors, windows, and trunk lids.

- Multi-channel designs combine weatherproofing, noise insulation, and vibration damping in a single profile.

Adhesive Backing:

Adhesive rubber seal strips simplify installation, allowing for quick application without the need for additional tools or fasteners.

These innovations ensure that sealing strips meet the demands of modern vehicles while maintaining durability and efficiency.

Rubber sealing strips, including extruded, flexible, and adhesive rubber seal strips, are essential for weatherproofing, noise reduction, and vibration damping in vehicles. Their ability to enhance passenger comfort, protect internal components, and improve vehicle longevity makes them indispensable in automotive design.

Explore our range of high-quality rubber sealing strips tailored for vehicle applications. Visit our website today to find the perfect solution for your weatherproofing and noise insulation needs!

Roinn

-

Lithium Battery Welding Machine | High-Precision, Fast, SafeNaidheachdanNov.17,2025

-

Aluminium Guide Roller | Anodized, Lightweight, Low-NoiseNaidheachdanNov.17,2025

-

Tofu Cat Litter Bulk – Eco, Low-Dust, Fast Clumping SupplyNaidheachdanNov.17,2025

-

Equipment for Lithium Cell Assembly | Automated & PreciseNaidheachdanNov.10,2025

-

Square File Tool – Precision Cut, Hardened Steel, VersatileNaidheachdanNov.10,2025

-

Lithium Ion Battery Assembly Machine | Automated, High-SpeedNaidheachdanNov.10,2025