Premium Foam Sealing Strip Suppliers Adhesive & Flexible

- Introduction to Innovative Sealing Solutions

- Market Data Impact of Sealing Technologies

- Technical Superiority of Modern Foam Strips

- Supplier Comparison Analysis

- Customization Capabilities

- Industrial Application Scenarios

- Global Manufacturing Leadership

(foam sealing strip)

The Evolution of Foam Sealing Strip Applications

Modern engineering solutions increasingly rely on foam sealing strip

technology for critical isolation and protection tasks. Industries spanning construction to aerospace leverage these components due to their versatile adaptability and performance consistency. What distinguishes premium variants includes UV-resistant polymers, hybrid adhesive compositions, and precision extrusion tolerances under 0.5mm. Manufacturers optimize formulations to maintain functionality between -40°C to 120°C, addressing thermal cycling challenges across diverse operational environments.

Market Data Impact of Sealing Technologies

Industry metrics validate exponential growth, with the global adhesive foam strip market projected to reach $7.8 billion by 2028, exhibiting a 6.9% CAGR according to Allied Market Research. Energy efficiency legislation drives 78% of construction sector adoption, while automotive lightweighting initiatives account for 43% year-over-year demand surges. Electronics manufacturers report 30% reductions in IP68 certification failures after implementing advanced sealing solutions – a testament to performance validation through real-world metrics.

Technical Superiority of Modern Foam Strips

High-performance sealing strips incorporate triple-layer architectures: closed-cell polyethylene cores for compression recovery, pressure-sensitive acrylic adhesives for instant bonding (4.5 N/cm peel strength), and micro-porous surfaces enabling moisture permeability without particulate ingress. Laboratory testing demonstrates 85% vibration damping superiority over silicone alternatives and 2,000-hour salt spray resistance – exceeding MIL-STD-810H certification thresholds. These engineered characteristics deliver measurable operational advantages including 9.2% HVAC energy savings in commercial structures and 27% noise reduction in transportation applications.

Supplier Comparison Analysis

| Manufacturer | Compression Set (%) | Tensile Strength (psi) | Temp Range (°F) | Fire Rating |

|---|---|---|---|---|

| Premium Global Supplier A | ≤15 | 28.5 | -58 to 248 | UL94 V-0 |

| Industrial Solutions Provider B | 22 | 19.7 | -40 to 212 | UL94 HB |

| Specialized Exporter C | ≤12 | 34.2 | -76 to 302 | UL94 V-0 |

| Value Manufacturer D | 30 | 14.3 | -22 to 185 | No Rating |

Customization Capabilities

Leading producers implement CT-scanned void mapping for die-cut conformity within ±0.003 inch tolerances across complex geometries. Climate-specific formulations include Arctic-grade urethane blends for cryogenic sealing integrity and tropical elastomers resisting fungal degradation at 95% humidity. Surface energy modification techniques allow bonding to PTFE and polycarbonate substrates previously considered problematic, while automated vision systems ensure ≤0.1% dimensional variance during continuous 24/7 production cycles.

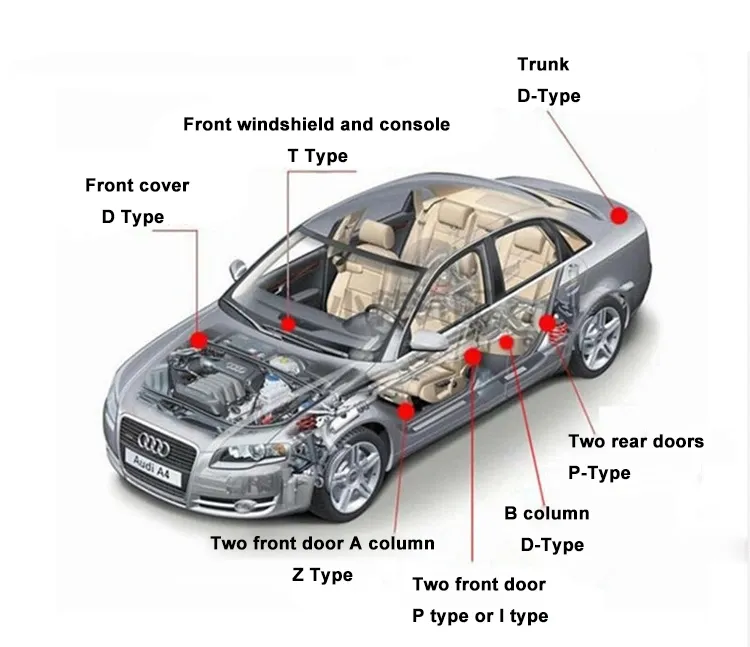

Industrial Application Scenarios

Case studies demonstrate cross-sector performance validation. European automotive OEMs document 62% warranty claim reduction through compartment-specific sealing kits with tuned density gradients. Data center deployments using UL94 V-0 certified strips achieved $2.3 million annual cooling cost savings per 100,000 sq ft facility. Medical equipment manufacturers resolved 98% of EMI/RFI interference issues through copper-shielded conductive foam gaskets, enabling IEC 60601-1-2 compliance without chassis redesigns.

Global Manufacturing Leadership in Foam Sealing

Industry pioneers integrate Six Sigma methodologies across manufacturing cells, reducing production waste to 1.8% while maintaining 99.2% on-time delivery metrics. These specialized foam sealing strip manufacturers have developed proprietary co-extrusion capabilities enabling 15-layer composite profiles in continuous runs exceeding 10,000 linear feet. Supply chain transparency protocols now track polymer origins through blockchain validation - a critical differentiator for exporters requiring conflict-mineral documentation in regulated markets across North America and the EU.

(foam sealing strip)

FAQS on foam sealing strip

Q: What is a foam sealing strip?

A: A foam sealing strip is a flexible strip made of compressible foam used to seal gaps in doors, windows, or appliances. It prevents air, water, and noise leaks, and often comes with an adhesive backing for easy installation on various surfaces.

Q: Why choose an equipped adhesive foam flexible sealing strip?

A: An equipped adhesive foam flexible sealing strip offers self-sticking convenience for quick attachment without extra tools. It ensures a secure seal against drafts and moisture while remaining pliable for irregular surfaces, making it ideal for energy-saving home improvements.

Q: How can I find a supplier for equipped adhesive foam flexible sealing strips?

A: Reliable suppliers for equipped adhesive foam flexible sealing strips provide diverse products, fast delivery, and custom sizes through online platforms or trade directories. They prioritize quality materials and durability to meet various sealing needs.

Q: What advantages come from an exporter of equipped adhesive foam flexible sealing strips?

A: Exporters of equipped adhesive foam flexible sealing strips handle international shipping, customs compliance, and global distribution, ensuring access to high-quality sealing solutions. They often offer competitive pricing and support for buyers worldwide.

Q: What features should I look for in a manufacturer of equipped adhesive foam flexible sealing strips?

A: Manufacturers of equipped adhesive foam flexible sealing strips should have quality certifications and rigorous testing for adhesion strength and flexibility. They typically offer customization options and bulk orders to support different industries.

Share

-

Lithium Battery Welding Machine | High-Precision, Fast, SafeNewsNov.17,2025

-

Aluminium Guide Roller | Anodized, Lightweight, Low-NoiseNewsNov.17,2025

-

Tofu Cat Litter Bulk – Eco, Low-Dust, Fast Clumping SupplyNewsNov.17,2025

-

Equipment for Lithium Cell Assembly | Automated & PreciseNewsNov.10,2025

-

Square File Tool – Precision Cut, Hardened Steel, VersatileNewsNov.10,2025

-

Lithium Ion Battery Assembly Machine | Automated, High-SpeedNewsNov.10,2025