Lithium Cell Machinery: High-Efficiency Battery Assembly Lines

Advancing Battery Production with Precision Lithium Cell Machinery

The global push towards sustainable energy solutions has dramatically amplified the demand for advanced energy storage, primarily lithium cell machinery. As industries pivot towards electric vehicles (EVs), renewable energy integration, and robust portable electronics, the efficiency, reliability, and scalability of lithium-ion battery production have become paramount. This article explores the intricate world of modern battery manufacturing equipment, highlighting critical trends, technical specifications, and strategic advantages that define leadership in this dynamic sector.

Modern lithium ion battery production equipment is not merely about assembly; it represents a symphony of precision engineering, advanced automation, and stringent quality control designed to meet the ever-increasing performance and safety demands of the market. From raw material handling to final pack testing, every stage of the lithium ion battery assembly line is optimized for throughput, consistency, and cost-effectiveness.

Industry Trends Driving Lithium Cell Machinery Innovation

The landscape of lithium-ion battery manufacturing is undergoing rapid evolution, driven by several key industry trends:

- Increased Automation and Robotics: To enhance precision, reduce labor costs, and improve throughput, advanced robotics and intelligent automation are becoming standard across lithium cell machinery. This includes automated material handling, precision welding, and robotic assembly stations.

- Enhanced Quality Control and Data Analytics: Real-time monitoring, AI-driven inspection systems, and comprehensive data analytics are crucial for identifying defects early, optimizing processes, and ensuring superior product quality. This data-centric approach minimizes waste and maximizes yield.

- Sustainable Manufacturing Practices: There's a growing emphasis on energy efficiency, waste reduction, and the use of environmentally friendly processes in battery production. Machinery designers are incorporating features that reduce energy consumption and facilitate material recycling.

- Flexibility and Customization: Manufacturers require production lines that can adapt to various cell formats (cylindrical, prismatic, pouch) and battery chemistries (NMC, LFP, NCA) to meet diverse application needs. Modular designs and reconfigurable lithium ion battery assembly machine solutions are gaining prominence.

- Scalability: With demand soaring, production lines must be easily scalable to meet rapidly expanding market needs, from pilot production to giga-factory scale.

Detailed Process Flow of Lithium Cell Machinery

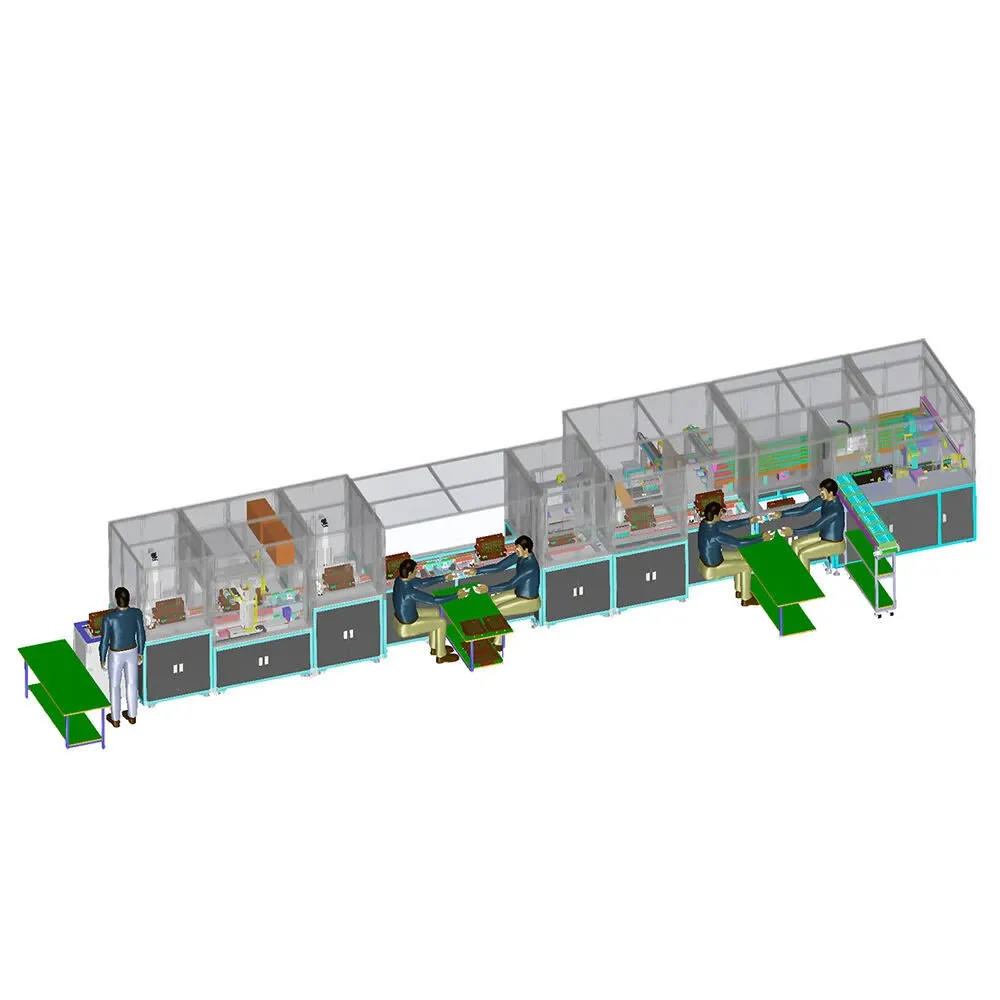

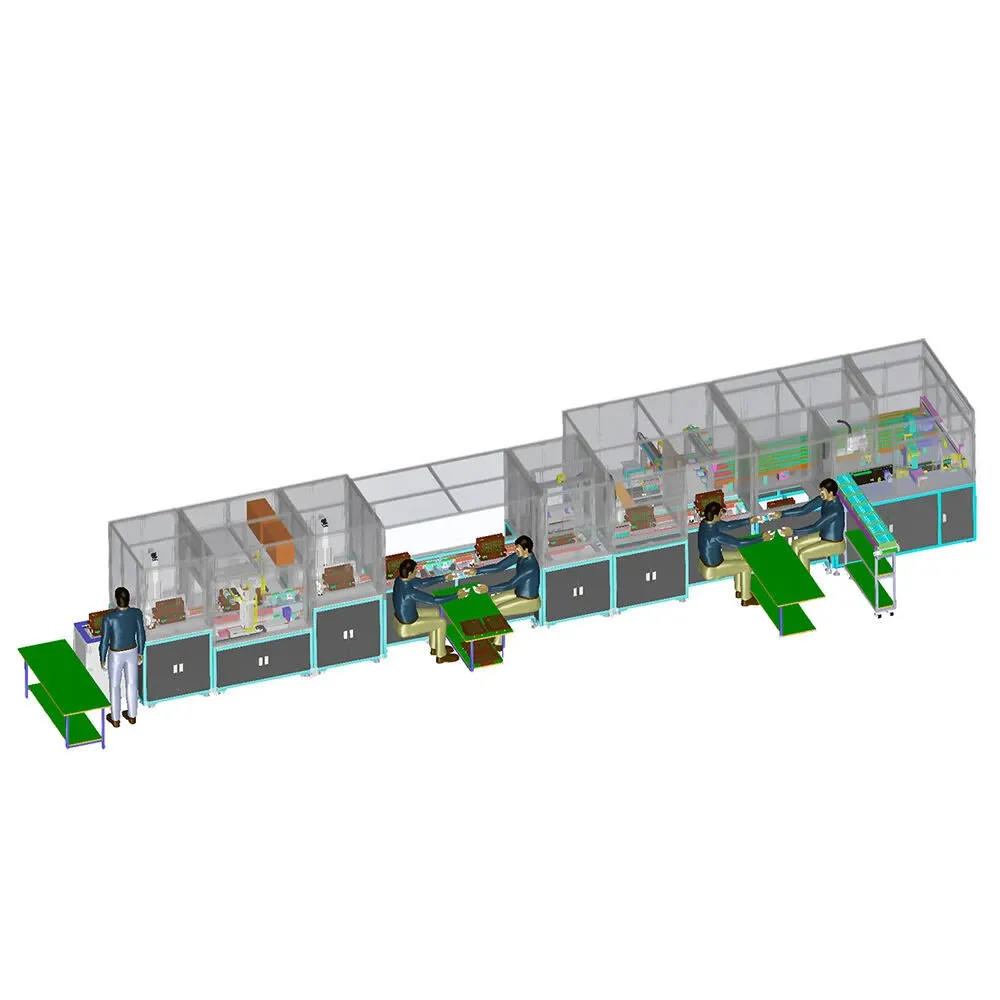

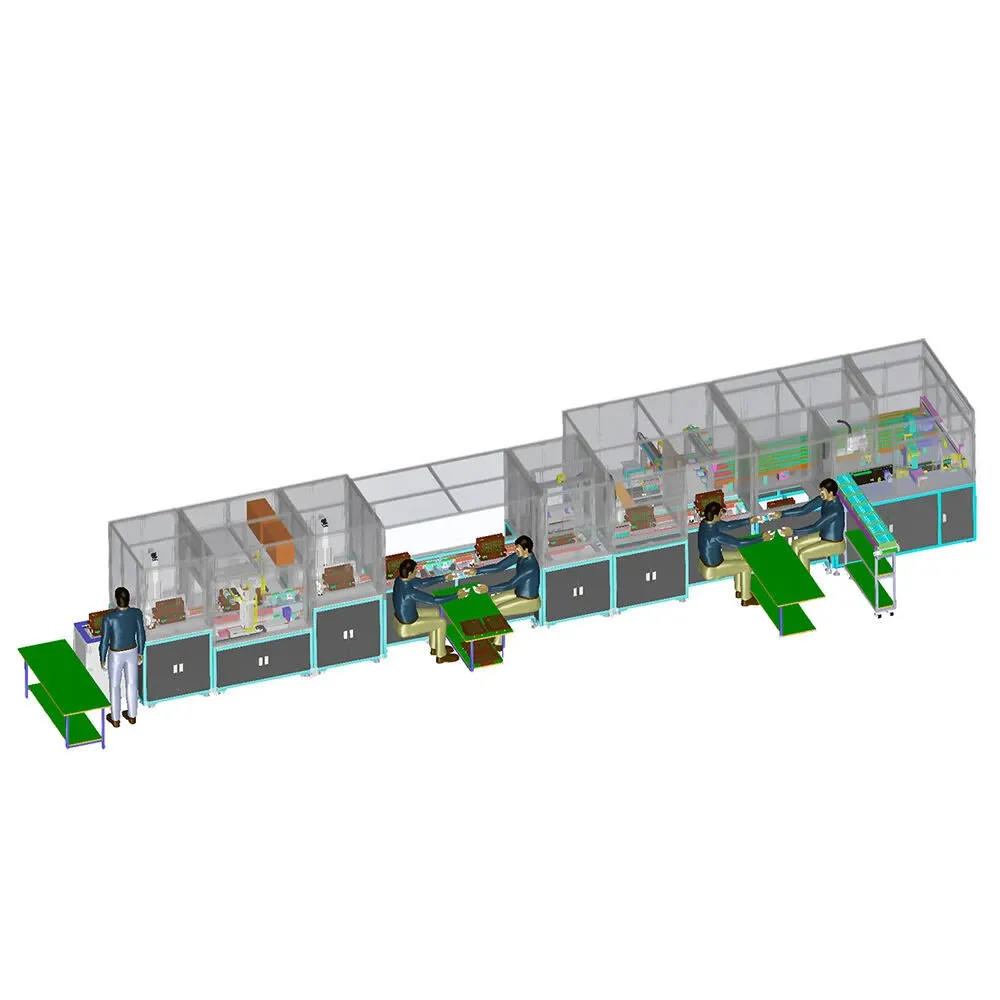

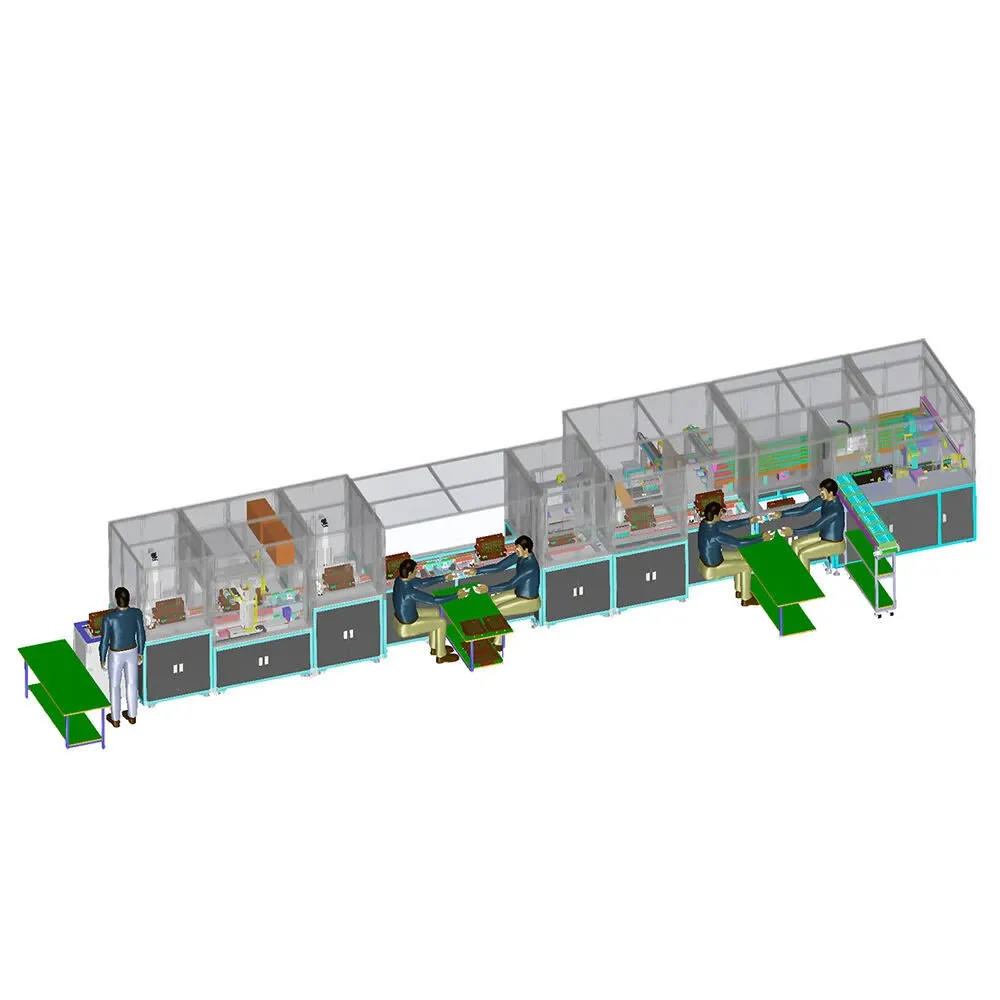

The manufacturing of an Advanced New Energy Lithium Battery PACK Automated Assembly Production Line System involves a sophisticated multi-stage process, ensuring high precision and efficiency from raw cell to finished battery pack.

Key Process Steps and Machinery Operations:

1. Cell Incoming Inspection & Sorting

Raw lithium cells (e.g., NCM, LFP chemistries, cylindrical 18650/21700, or pouch/prismatic cells) undergo automated inspection for voltage, internal resistance, physical dimensions, and surface defects. Cells are sorted into specific groups to ensure uniformity within a battery module, a critical step for pack longevity and performance.

2. Module Assembly (Cell Placement & Fixturing)

Sorted cells are precisely placed into module frames or holders. This step often utilizes high-precision robotic arms (CNC controlled) to ensure accurate alignment, minimizing stress and optimizing spacing for thermal management. Materials include engineered plastics and aluminum alloys for structural integrity.

3. Interconnect Welding (Busbar Connection)

Cells are connected in series/parallel configurations using high-conductivity busbars (typically nickel-plated copper or aluminum). Automated laser welding or ultrasonic spot welding machines perform these critical connections with high precision, ensuring minimal resistance and maximum current transfer. Welding parameters are rigorously controlled for robustness and consistency, adhering to standards like AWS D17.1.

4. BMS Installation & Wiring

The Battery Management System (BMS) is integrated, responsible for monitoring cell voltage, temperature, current, and balancing. This step involves precise soldering and wiring of sensor leads to the BMS board. Automated wiring robots ensure accurate and robust connections.

5. Module & Pack Encapsulation

Modules are assembled into the final pack enclosure. This involves applying thermal conductive materials (e.g., silicone pads, gap fillers) for heat dissipation and sealing the pack against environmental ingress. Advanced sealing techniques like robotic dispensing and automated screw fastening are employed. Materials used are often aluminum, steel, or composites, chosen for strength, weight, and thermal properties.

6. End-of-Line (EOL) Testing & Certification

The finished battery pack undergoes comprehensive EOL testing, including capacity testing, internal resistance, insulation resistance, short-circuit protection, overcharge/discharge protection, and communication protocol validation. These tests ensure compliance with safety standards such as ISO 12405, UL 2580, and UN 38.3. This stage also includes burn-in tests and detailed performance validation over specified cycles.

Target Industries and Advantages:

The advanced lithium cell machinery systems are designed for high-volume manufacturing environments, primarily serving the new energy sector. Target industries include: electric vehicle manufacturing (passenger cars, commercial vehicles), grid-scale energy storage systems (ESS), portable power solutions, and industrial robotics. The machinery's robust design ensures a service life typically exceeding 10 years with proper maintenance.

Typical Application Scenario Advantages: In an EV battery production facility, our automated lines demonstrate significant advantages: achieving energy saving through optimized processing (e.g., efficient welding power consumption), enhanced corrosion resistance in components via material selection (e.g., stainless steel frames for cleanroom environments), and superior throughput compared to manual or semi-automated lines. A typical line can achieve 10-20% energy savings per pack and 99.8% process yield, dramatically reducing operational costs and material waste.

Technical Specifications and Parameters

Our Advanced New Energy Lithium Battery PACK Automated Assembly Production Line System embodies cutting-edge engineering. Below is a detailed overview of typical technical parameters:

Product Specification Table: Advanced Lithium Battery PACK Assembly Line

| Parameter | Specification |

|---|---|

| Production Capacity | Up to 50,000 battery packs/year (scalable), or 80-120 packs/hour for typical EV modules (e.g., 8-12 kWh). |

| Applicable Cell Types | Cylindrical (18650, 21700, 46800), Prismatic, Pouch cells (adaptable through modular fixtures). |

| Assembly Precision | ±0.05 mm (Cell placement), ±0.02 mm (Welding spot accuracy). |

| Welding Technology | High-speed Laser Welding (fiber laser 1000W-6000W) and/or Ultrasonic Spot Welding. |

| Automation Level | Fully Automated (robotics, AGVs, intelligent control systems) with minimal human intervention. |

| Vision Inspection Systems | Integrated high-resolution cameras for defect detection, position verification, and quality control at each stage. |

| BMS Communication | CAN, LIN, Ethernet for real-time data exchange and control. |

| Safety Standards | CE, ISO 13849 (functional safety), IEC 60204 (electrical safety). |

| Yield Rate | ≥ 99.8% (process yield), ≥ 98% (equipment uptime). |

| Power Consumption | Optimized for energy efficiency, typically 150-300 kW for a full line (peak). |

Application Scenarios and Technical Advantages

Our lithium ion battery production equipment is designed to meet the rigorous demands of various high-stakes applications.

- Electric Vehicle (EV) Battery Manufacturing: From compact city cars to heavy-duty commercial vehicles, our lines produce battery packs for diverse EV platforms. The precision and speed are crucial for meeting ambitious production targets and maintaining the highest safety standards for automotive applications.

- Grid-Scale Energy Storage Systems (ESS): For utility companies and renewable energy integrators, our machinery builds large-format battery packs capable of stabilizing grids, storing excess solar/wind energy, and providing backup power. Robust welding and thermal management integration are key advantages.

- Industrial & Robotic Applications: High-power, long-life battery packs for automated guided vehicles (AGVs), industrial robots, and heavy-duty electric tools benefit from the consistent quality and durability ensured by our assembly lines.

- Portable Power Solutions & Consumer Electronics: While our primary focus is large-scale, the core technologies can be adapted for high-density, reliable packs in professional-grade portable power stations or specialized consumer devices requiring superior performance and safety.

Key Technical Advantages:

- Superior Welding Integrity: Our laser welding stations ensure minimal heat-affected zones, high pull strength, and consistent electrical connections, extending the battery pack's cycle life and enhancing safety. This surpasses traditional resistance welding methods in quality and repeatability.

- Advanced Thermal Management Integration: The design incorporates precise application of thermal interface materials and integrates coolant pathways, critical for maintaining optimal operating temperatures and preventing thermal runaway.

- Modular & Scalable Architecture: The production line is designed with modular components, allowing for easy expansion, reconfiguration, and integration of new technologies as battery chemistries and form factors evolve.

- Intelligent Control & Diagnostics: A sophisticated PLC/SCADA system with integrated AI ensures real-time process monitoring, predictive maintenance, and comprehensive data logging. This leads to higher uptime and proactive problem-solving.

- High Throughput & Yield: Through optimized cycle times and minimized material handling, our lithium cell machinery achieves industry-leading production rates and reduces waste, directly impacting the total cost of ownership.

Vendor Comparison and Customized Solutions

Choosing the right battery assembly line manufacturers is a strategic decision that impacts long-term operational efficiency and product quality. A thorough vendor comparison goes beyond initial cost and delves into critical aspects of capability, support, and innovation.

Vendor Comparison Framework:

| Feature/Attribute | Our Solution (Example) | Typical Competitor (General) |

|---|---|---|

| Automation & Robotics | Integrated 6-axis robots, AGVs, machine vision. Full automation. | Semi-automated or less integrated robotic solutions. |

| Welding Technology | High-power Fiber Laser (up to 6kW) with real-time weld monitoring. | Lower power laser or resistance welding, less precise control. |

| Software & Control | Proprietary MES/SCADA integration, AI-driven predictive maintenance. | Basic PLC control, limited data logging, less intelligent. |

| Adaptability (Cell Types) | Modular fixturing for cylindrical, prismatic, pouch cells with quick changeover. | Dedicated lines for specific cell types, longer changeover times. |

| After-Sales Support | Global 24/7 remote support, local service engineers, comprehensive training. | Limited regional support, less extensive training, slower response times. |

| Certifications | ISO 9001, CE, TUV, adherence to UL, IEC, UN standards. | May have basic CE, but fewer comprehensive industrial certifications. |

Customized Solutions:

Recognizing that no two battery manufacturing facilities are identical, we specialize in providing highly customized lithium ion battery assembly line solutions. Our engineering team works closely with clients to:

- Tailor Production Capacity: From pilot lines for R&D to giga-factory scale, our systems are designed to match precise output requirements.

- Integrate Specific Cell Chemistries & Form Factors: Adaptable tooling and software ensure compatibility with emerging battery technologies and custom cell designs.

- Optimize Factory Layout: Our solutions seamlessly integrate into existing or planned facility layouts, optimizing space utilization and material flow.

- Develop Bespoke Testing Regimes: Beyond standard EOL tests, we can implement specialized testing protocols to meet unique product performance or safety criteria.

- Ensure Regulatory Compliance: We configure systems to meet specific regional and industry safety, environmental, and quality standards (e.g., FDA for medical, aerospace specific).

Application Case Studies

Our advanced lithium cell machinery has consistently delivered measurable improvements for leading battery manufacturers across the globe.

Case Study 1: High-Volume EV Battery Production

A major automotive Tier 1 supplier needed to scale up their EV battery pack production by 300% within two years to meet new vehicle model launches. We implemented a fully automated lithium ion battery assembly machine line capable of handling 21700 cylindrical cells. The solution integrated robotic cell sorting, high-speed laser welding with in-situ quality verification, and an automated BMS installation module. The client achieved:

- Production Throughput: Increased from 30 packs/hour to 100 packs/hour, exceeding the target.

- Quality Enhancement: Weld defect rate reduced by 85%, leading to an overall pack rejection rate of less than 0.05%.

- Operational Efficiency: Labor requirements for assembly reduced by 70%, reallocating skilled personnel to quality control and R&D.

Case Study 2: Modular Energy Storage System (ESS) Line

An emerging ESS provider required a flexible production line for modular battery units (100 kWh to 1 MWh) utilizing prismatic LFP cells. The challenge was to accommodate varying module sizes and integrate a proprietary cooling system. Our customized solution provided:

- Flexibility: Quick-change tooling fixtures allowed seamless transitions between different module configurations within 30 minutes.

- Integration: Seamless integration of the client's unique liquid cooling plate assembly into the automated process.

- Yield Improvement: Achieved a first-pass yield of 99.5% for assembled modules, a 15% improvement over their previous semi-manual process.

Trustworthiness and Support

At the core of our offering is a commitment to trustworthiness, backed by robust support mechanisms and transparent processes.

Frequently Asked Questions (FAQ)

Q: What is the typical lead time for a custom lithium cell machinery line?

A: Lead times vary based on complexity and customization. Standard configurations typically range from 6-8 months from order confirmation to factory acceptance test (FAT). Highly customized or large-scale lines may extend to 10-14 months.

Q: What kind of warranty is offered with your lithium ion battery production equipment?

A: We provide a standard 12-month warranty on all mechanical and electrical components from the date of final acceptance. Extended warranty options are available upon request, covering critical components and preventative maintenance services.

Q: What post-sales support is available?

A: Our comprehensive after-sales support includes 24/7 remote technical assistance, on-site engineer deployment, spare parts management, and scheduled preventative maintenance programs. We also offer advanced operator training and process optimization consulting.

Q: How do you ensure compliance with international safety standards?

A: All our machinery is designed and built to meet rigorous international safety standards, including CE, ISO 13849 (functional safety), and relevant industry-specific norms like UL for battery pack production. We provide comprehensive documentation and certification support.

Lead Time and Fulfillment

Our project management methodology ensures transparent communication and adherence to agreed-upon timelines. From initial consultation and design to manufacturing, installation, and commissioning, every phase is meticulously planned and executed. We maintain strong supply chain relationships to ensure timely procurement of high-quality components, minimizing delays and ensuring predictable delivery schedules.

Warranty Commitments

We stand behind the quality and performance of our lithium cell machinery. Our warranty policy covers defects in materials and workmanship, providing peace of mind and protecting your investment. Details are clearly outlined in our contract agreements, with options for extended coverage to suit long-term operational strategies.

Customer Support Information

Our dedicated customer support team is available globally. Clients receive a dedicated project manager and access to our technical support portal, ensuring prompt assistance with operational queries, troubleshooting, and maintenance guidance. Training programs are tailored to equip your staff with the necessary skills for optimal system operation and first-level maintenance.

Conclusion

The advancements in lithium cell machinery are pivotal in accelerating the global energy transition. By providing highly automated, precise, and reliable lithium ion battery assembly line systems, manufacturers can achieve unprecedented levels of efficiency, quality, and scalability. Our commitment to innovation, adherence to stringent quality standards, and comprehensive customer support positions us as a trusted partner for leaders in the new energy sector. As the demand for high-performance lithium-ion batteries continues to soar, investing in cutting-edge production equipment is not just an operational necessity but a strategic imperative for future success.

References

- International Electrotechnical Commission (IEC) Standards for Secondary Cells and Batteries containing Alkaline or other Non-acid Electrolytes.

- Underwriters Laboratories (UL) Standard for Safety for Batteries for Use in Electric Vehicles (UL 2580).

- International Organization for Standardization (ISO) 9001:2015 - Quality Management Systems – Requirements.

- American Welding Society (AWS) D17.1 - Specification for Fusion Welding for Aerospace Applications.

- United Nations (UN) Manual of Tests and Criteria, Section 38.3 - Lithium Metal and Lithium Ion Batteries.

Share

-

Lithium Battery Welding Machine | High-Precision, Fast, SafeNewsNov.17,2025

-

Aluminium Guide Roller | Anodized, Lightweight, Low-NoiseNewsNov.17,2025

-

Tofu Cat Litter Bulk – Eco, Low-Dust, Fast Clumping SupplyNewsNov.17,2025

-

Equipment for Lithium Cell Assembly | Automated & PreciseNewsNov.10,2025

-

Square File Tool – Precision Cut, Hardened Steel, VersatileNewsNov.10,2025

-

Lithium Ion Battery Assembly Machine | Automated, High-SpeedNewsNov.10,2025