Suppliers for Battery Production Line and Assembly Solutions

Battery Assembly Line Suppliers A Key to Advancing Energy Solutions

In recent years, the global demand for batteries—especially lithium-ion batteries—has skyrocketed due to the proliferation of electric vehicles (EVs), renewable energy systems, and portable electronic devices. As this demand continues to grow, so too does the importance of reliable and efficient battery assembly line suppliers. These suppliers play a crucial role in shaping the future of energy solutions, ensuring the production of high-quality batteries that meet the ever-increasing needs of consumers and industries alike.

The Importance of Battery Assembly Lines

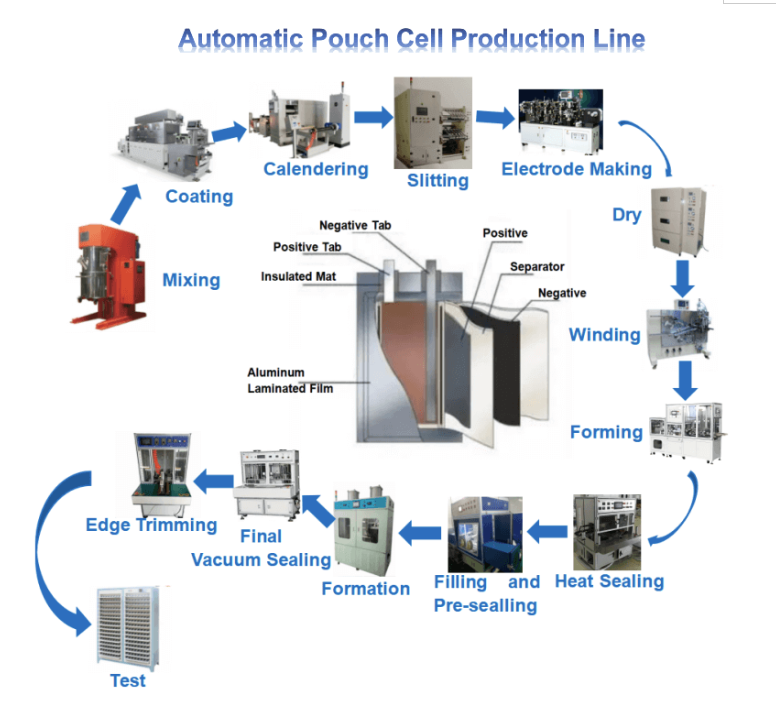

Battery assembly lines are specialized manufacturing setups designed to produce batteries efficiently and at scale. The complexity of battery technology, combined with the need for precision in assembly, makes the role of these lines indispensable. An effective assembly line streamlines various stages of production, from cell formation to packaging, ensuring that batteries are not only produced quickly but also adhere to stringent quality standards.

Key Suppliers and Their Solutions

Several key players in the market specialize in battery assembly line solutions. Companies like Siemens, KUKA, and ASM Pacific Technology offer advanced automation technologies that enhance production efficiency while minimizing human error. These suppliers provide a range of equipment, including robotic arms for handling delicate components, conveyor systems for rapid transport of materials, and software for monitoring and optimizing the assembly process.

1. Siemens Known for its innovative automation solutions, Siemens provides comprehensive assembly line setups that integrate advanced robotics and digital monitoring systems. Their assembly lines are designed to increase throughput while maintaining quality control, which is vital in the competitive battery market.

2. KUKA This German company is a leader in industrial robotics and automation technology. KUKA's robotic solutions are particularly suited for battery assembly, offering flexibility and precision. Their systems can be programmed to handle various battery sizes and configurations, making them an attractive choice for suppliers looking to scale production.

3. ASM Pacific Technology Specializing in semiconductor manufacturing, ASM has extended its expertise into the battery sector. Their solutions focus on precision handling and assembly, with an emphasis on cleanroom technologies essential for maintaining battery integrity.

battery assembly line suppliers

Advancements in Technology

The landscape of battery assembly is rapidly evolving, propelled by advancements in technology. Artificial intelligence (AI) and machine learning are beginning to play a significant role in optimizing manufacturing processes. Through predictive analytics, suppliers can foresee equipment failures before they occur, reducing downtime and increasing efficiency. Additionally, the implementation of the Internet of Things (IoT) allows for real-time data collection and analysis, enabling manufacturers to fine-tune their operations continually.

Moreover, sustainable practices are becoming increasingly important. Suppliers are now focusing on environmentally friendly materials and production methods. This shift not only addresses regulatory pressures but also aligns with the growing consumer demand for sustainable products. Innovative recycling solutions for battery components are being developed, ensuring that production processes are as sustainable as possible.

Challenges Faced by Battery Assembly Line Suppliers

Despite the advancements, battery assembly line suppliers face several challenges. The rapid evolution of battery technology means that assembly lines must continually adapt to accommodate new chemistries and configurations. Furthermore, the supply chain disruptions caused by global events, such as the COVID-19 pandemic, have highlighted vulnerabilities in sourcing raw materials, particularly for lithium and cobalt.

The competition is also intensifying as more companies enter the battery manufacturing space. This makes it imperative for assembly line suppliers to offer not only innovative solutions but also competitive pricing and exceptional customer service to retain their market position.

Conclusion

As the world shifts towards renewable energy and electric mobility, the role of battery assembly line suppliers becomes increasingly vital. They are the backbone of battery production, ensuring that high-quality and efficient solutions reach the market. By embracing technological advancements and sustainable practices, these suppliers can navigate the challenges ahead and contribute to a greener future. As the industry continues to grow, the partnership between battery manufacturers and assembly line suppliers will be crucial in driving innovation and meeting the demands of a rapidly changing world. The future of energy appears bright, and much of that light shines from the batteries we depend on every day.

Share

-

The Best Lubricants for Aluminum Roller GuidesNewsJul.23,2025

-

Slitting Machine Applications in the Packaging IndustryNewsJul.23,2025

-

Rolling Roller Balancing Techniques for Smooth OperationNewsJul.23,2025

-

How To Optimize An EV Battery Assembly LineNewsJul.23,2025

-

Energy Efficiency in Modern Battery Formation EquipmentNewsJul.23,2025

-

Automation Trends in Pouch Cell Assembly EquipmentNewsJul.23,2025