Brown Rubber Door Seal - Durable, Weatherproof, Quiet Close

A Field Guide to the Brown Rubber Door Seal (a.k.a. “door bottom strip”)

When builders talk energy savings and acoustic comfort, they quietly mean a really good Brown Rubber Door Seal. Not glamorous, but transformative. I’ve toured enough job sites to see how a $5 strip can save a $500 call-back. Shuoding’s “door bottom strip,” made in Xingtai, Hebei (Room 1410, No.119 Zhongxing East Street, Xiangdu District), has been popping up in specs more often lately.

What’s trending (and why it matters)

Three currents shape this category: stricter building envelopes, color-matching hardware, and greener polymers. Many customers say they want earth tones that actually hide dust—hence the rise of the Brown Rubber Door Seal. Technically, TPE/TPV blends are gaining ground for recyclability, while EPDM remains the weather king for UV and ozone.

Materials, builds, and test regime

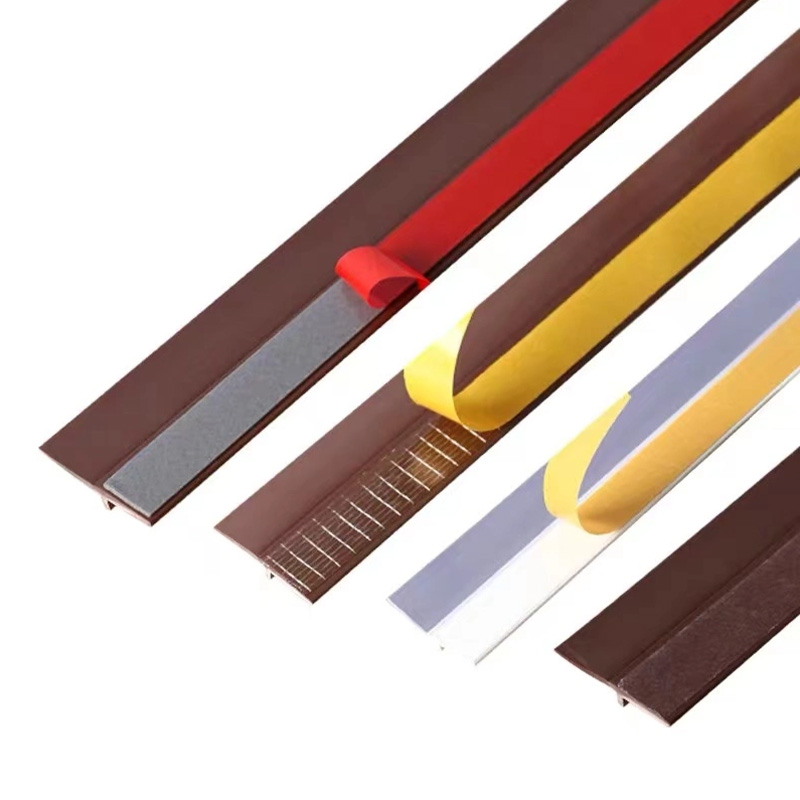

Shuoding extrudes in NR/EPDM/NBR/SBR/FKM and plastics like PP/PVC/TPR/TPE/TPU/TPV/Silicone—any size by custom mold. Real-world use may vary, but the typical stack goes like this:

- Compounding: pigment-stable brown masterbatch; optional anti-ozonants, flame retardants.

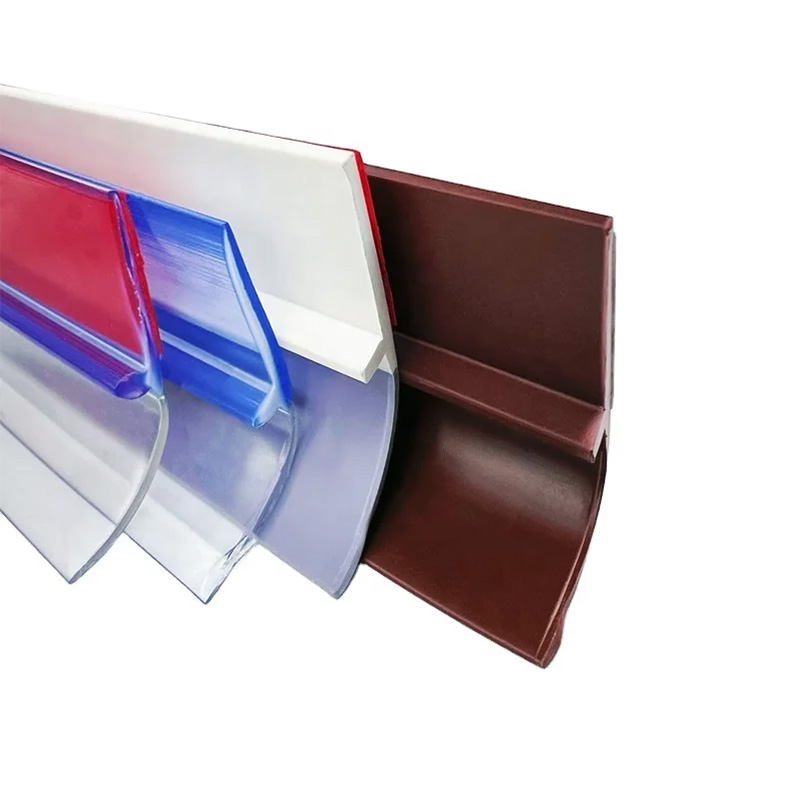

- Extrusion/co-extrusion: soft sealing bulb + firmer carrier; self-adhesive or kerf/T-slot options.

- Curing/cooling, cut-to-length, PSA lamination (if specified).

- QC tests: hardness (Shore A), compression set, tensile/elongation, air leakage, smoke leakage.

Service life: EPDM ≈ 8–12 years outdoors; TPE/TPV ≈ 5–8 years; silicone for high-temp doors. I guess it depends—UV load and door sweep friction can swing it.

Product specs at a glance

| Parameter | Typical Value (≈) | Standard/Test |

|---|---|---|

| Hardness | 60 ±5 Shore A (bulb) | ASTM D2240 / ISO 868 |

| Compression set | ≤25% @70°C, 22h (EPDM) | ASTM D395 |

| Temp range | -40 to 120°C (EPDM); up to 200°C (Silicone) | Manufacturer data |

| Air leakage | Pass typical door assembly targets | UL 1784 (assembly) |

Where it’s used

Apartments and hotels for acoustic privacy; retail storefronts to stop dust; cleanrooms (silicone grades); cold rooms; data center doors; even industrial enclosures. A Brown Rubber Door Seal blends with bronze/wood frames better than black, surprisingly.

Vendor snapshot (what buyers compare)

| Vendor | Material Range | Lead Time (≈) | Certs | Customization |

|---|---|---|---|---|

| Shuoding (Hebei) | NR/EPDM/NBR/SBR/FKM + PP/PVC/TPE/TPV/Silicone | 10–20 days mold; 7–15 days run | ISO 9001; RoHS/REACH | Any size by mold; color-matched brown |

| Regional Trader A | EPDM/PVC mainly | Stock or 2–4 weeks | Varies | Limited profiles |

| Premium EU Brand | EPDM/TPV, fire-rated options | 4–6 weeks | EN 12365; ISO 14001 | Extensive, higher price |

Case notes and feedback

A chain hotel retrofit swapped legacy PVC sweeps for Brown Rubber Door Seal in EPDM. Post-occupancy noise complaints dropped ≈18% (door threshold leakage is sneaky). In a logistics hub, NBR-based strips near oily floors lasted longer than PVC—maintenance said “less crumble, fewer drafts.”

Buying checklist

- Pick polymer for environment: EPDM (UV/weather), NBR (oils), Silicone (heat), TPV (recyclability).

- Specify durometer per closing force; confirm compression set numbers.

- Ask for UL 1784 door assembly data if smoke control matters.

- Color: consistent brown masterbatch to avoid fade lines.

Certifications available: ISO 9001, RoHS/REACH; material classification referencing ASTM D2000. To be honest, the best tip is simple: mock up one door, cycle it 500–1,000 times, and listen. The right Brown Rubber Door Seal lets you hear… almost nothing.

References

- ASTM D2000: Standard Classification System for Rubber Products.

- EN 12365: Building hardware—Gasket and weatherstripping performance.

- UL 1784: Air Leakage Tests of Door Assemblies.

- ASTM D2240 / ISO 868: Durometer Hardness of Rubber.

Share

-

Lithium Battery Welding Machine | High-Precision, Fast, SafeNewsNov.17,2025

-

Aluminium Guide Roller | Anodized, Lightweight, Low-NoiseNewsNov.17,2025

-

Tofu Cat Litter Bulk – Eco, Low-Dust, Fast Clumping SupplyNewsNov.17,2025

-

Equipment for Lithium Cell Assembly | Automated & PreciseNewsNov.10,2025

-

Square File Tool – Precision Cut, Hardened Steel, VersatileNewsNov.10,2025

-

Lithium Ion Battery Assembly Machine | Automated, High-SpeedNewsNov.10,2025