French Door Rubber Seal—Weatherproof, Easy Install?

The Quiet Power of a Good Seal: Field Notes on the E‑Type French Door Gasket

When contractors whisper about the quickest energy win on a renovation, they’re usually talking about the humble french door rubber seal. Not glamorous, sure, but it’s the difference between a cozy room and a drafty frustration. I’ve walked enough job sites to know: the profile and compound matter more than the marketing.

What’s Trending (and why E‑type is having a moment)

A few currents are shaping specs right now: higher door tolerances (blame bigger glass and slimmer frames), stricter energy codes, and—surprisingly—sound control in multi-family builds. The E-type geometry compresses predictably, so you get reliable closure pressure without slamming. In practice, a french door rubber seal in E-profile often wins on air-tightness per mm of deflection.

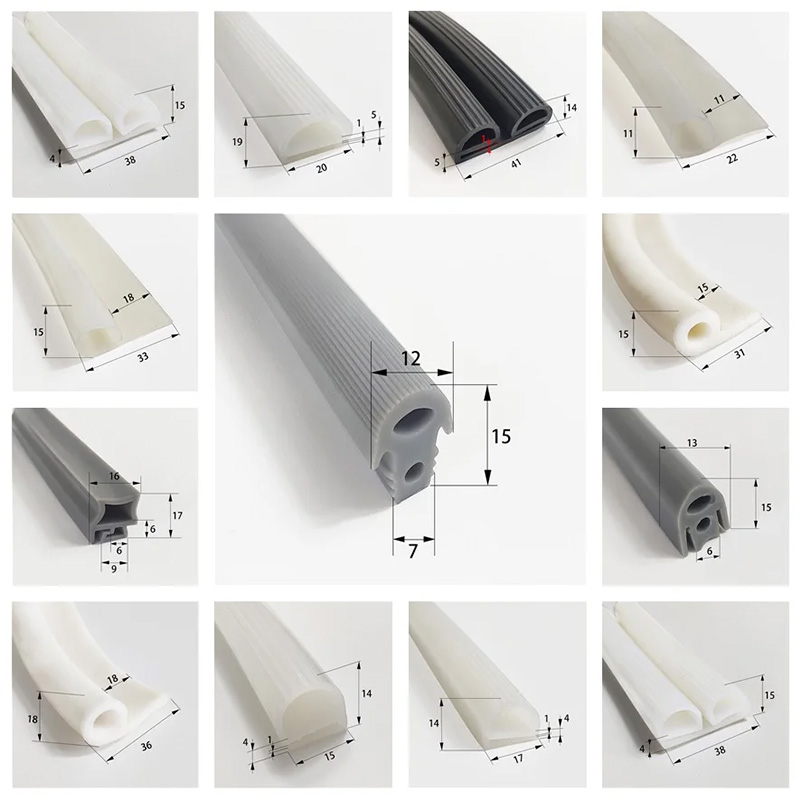

Core Specs (real-world ranges)

Product: Silicone E‑type sealing strip; made in Room 1410, No. 119 Zhongxing East Street, Xiangdu District, Xingtai City, Hebei, China.

| Parameter | Typical value (≈) | Notes |

|---|---|---|

| Material options | NR/EPDM/NBR/SBR/FKM/PP/PVC/TPR/TPE/TPU/TPV/Silicone | EPDM and Silicone are most common for doors |

| Shore A hardness | 50–75 | ISO 7619-1; pick softer for light-closing doors |

| Temperature range | EPDM: −40 to +120°C; Silicone: −50 to +200°C | Coastal and sauna doors love Silicone |

| Compression set (22h @70°C) | ≤25% (EPDM/Silicone) | ISO 815-1 / ASTM D395 |

| Tensile strength | 7–10 MPa | ISO 37; real-world use may vary |

| Color | Black or custom | UV-stable blacks favored |

| Adhesive option | 3M-type acrylic tape | Peel-and-stick retrofit |

| Profile & size | E‑type; by mold to drawing | Custom width/height; coils for fast install |

How it’s made (quick tour)

Materials are selected per climate and code (EPDM for ozone/UV, Silicone for high heat). The strip is extruded (often co-extruded if a soft bulb meets a firmer spine), vulcanized in continuous lines (microwave/hot-air), optionally post-cured for Silicone, then adhesive-laminated and talc-dusted for feedability. QC includes hardness (ISO 7619), tensile (ISO 37), compression set (ISO 815-1), and ozone resistance (ASTM D1149). Service life? In temperate installs, EPDM runs ≈8–12 years; Silicone often stretches to ≈15+ with basic care.

Where it works best

- Residential French doors: better winter tightness, softer close.

- Coastal villas: EPDM/Silicone resist salt and UV; less chalking.

- Hotels and clinics: quieter latching; noticeable sound damping.

- Data rooms and labs: helps with pressure and particulate control.

Many installers tell me a quality french door rubber seal cuts gap leakage by ≈20–30% versus no seal in A/B smoke tests (not scientific, but consistent). Formal performance can be referenced against EN 12365-1 and BS 6375-1 for weather tightness targets.

Vendor snapshot (apples-to-apples, roughly)

| Vendor | Materials | Certs/support | Lead time | MOQ | Custom tooling |

|---|---|---|---|---|---|

| XT ShuoDing (E‑type) | EPDM, Silicone, TPE | RoHS/REACH on request | ≈2–4 weeks | Flexible | Yes, by drawing/mold |

| EU Brand B | EPDM, TPV | CE documentation | ≈3–6 weeks | Medium | Limited profiles |

| Local Fab C | TPE/TPV | Basic material COAs | ≈1–2 weeks | Low | Quick prototypes |

Real installs (short, honest stories)

• Boutique hotel, Vancouver: swapped aging D‑profiles for E‑type Silicone; guest complaints about door slam noise dropped sharply within a week. Maintenance liked the peel-and-stick backing—fast turnover.

• Window/door fabricator, NRW Germany: EPDM 60A with low compression set; passed internal EN 12365-1 air/water tests with ≈10–15% better margins than prior stock, according to their QA notes.

Buying checklist

- Match hardness to hinge/lock effort; softer isn’t always better.

- Verify compression set and ozone test data (ISO 815-1 / ASTM D1149).

- Ask for gaskets to be sized to your door gap range (avoid over-compression).

- Request compliance notes where needed: REACH/RoHS; AAMA 701/702 references for weatherstrips.

If you need a custom french door rubber seal, send a simple drawing with gap, target deflection (≈30–40%), and any temperature extremes. Tooling for E‑type is straightforward and, frankly, cost-effective.

Citations

- ASTM D2000: Classification System for Rubber Products

- ISO 37: Rubber — Determination of tensile stress-strain

- ISO 815-1: Rubber — Determination of compression set

- EN 12365-1: Building hardware — Gasket performance

- BS 6375-1: Weather tightness of windows and doors

- AAMA 701/702: Weatherstripping Specifications

Share

-

Lithium Battery Welding Machine | High-Precision, Fast, SafeNewsNov.17,2025

-

Aluminium Guide Roller | Anodized, Lightweight, Low-NoiseNewsNov.17,2025

-

Tofu Cat Litter Bulk – Eco, Low-Dust, Fast Clumping SupplyNewsNov.17,2025

-

Equipment for Lithium Cell Assembly | Automated & PreciseNewsNov.10,2025

-

Square File Tool – Precision Cut, Hardened Steel, VersatileNewsNov.10,2025

-

Lithium Ion Battery Assembly Machine | Automated, High-SpeedNewsNov.10,2025