Rolling Roller Manufacturer | Wear-Resistant Work Rolls

rolling roller,roller,roller manufacturer,roll supplier,roll,work rolls,rolling intermediate roll is a key solution in the new energy industry industry, specifically within Lithium battery manufacturing and Lithium battery production equipment. This article explores how XINGTAI SHUODING TRADING CO.,LTD supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- rolling roller,roller,roller manufacturer,roll supplier,roll,work rolls,rolling intermediate roll Overview

- Benefits & Use Cases of rolling roller,roller,roller manufacturer,roll supplier,roll,work rolls,rolling intermediate roll in Lithium battery production equipment

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in new energy industry

- Conclusion on rolling roller,roller,roller manufacturer,roll supplier,roll,work rolls,rolling intermediate roll from XINGTAI SHUODING TRADING CO.,LTD

rolling roller,roller,roller manufacturer,roll supplier,roll,work rolls,rolling intermediate roll Overview

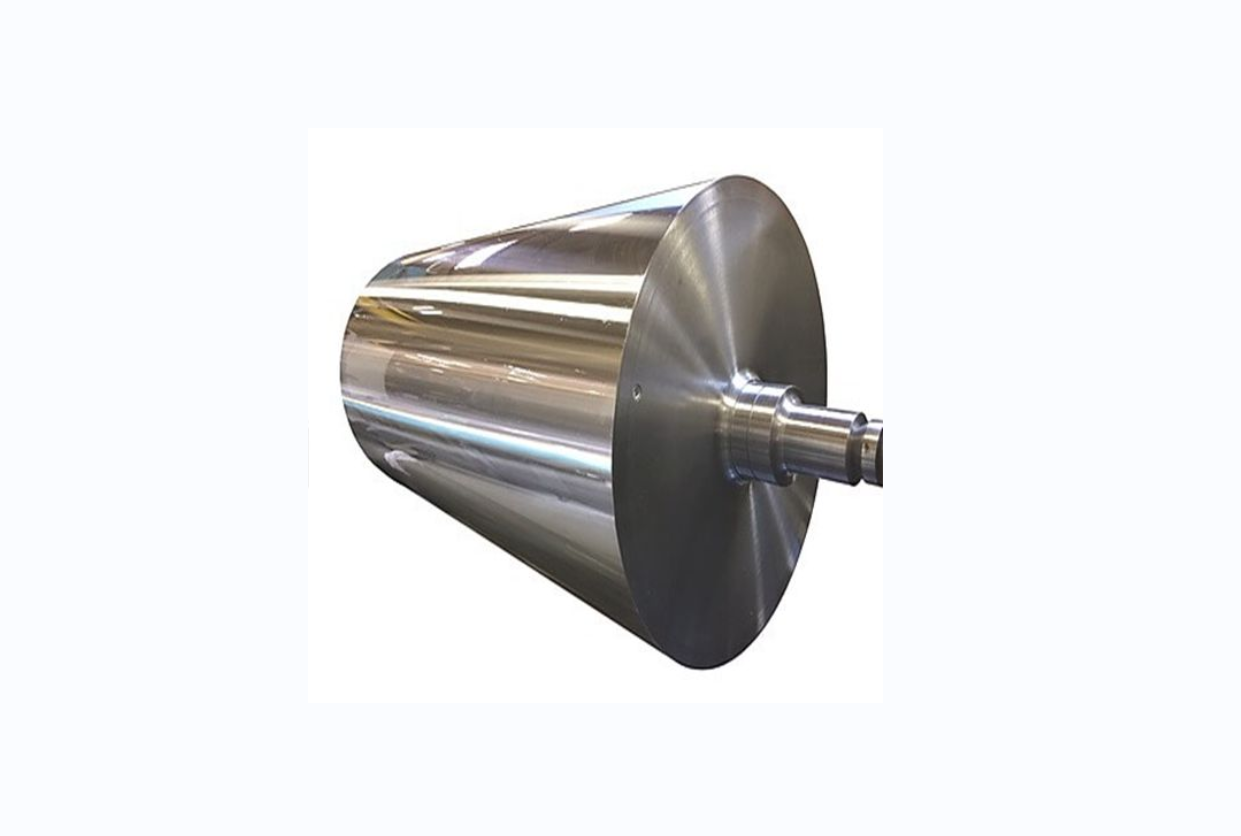

In lithium battery manufacturing, the rolling roller—often referred to as work rolls or a rolling intermediate roll within multi-high calender stands—is mission-critical to electrode calendering, foil finishing, and precision conveying. These rolls control thickness, density, and surface quality of cathode and anode sheets, directly impacting cell capacity, safety, and yield. As a specialized roller manufacturer and trusted roll supplier, XINGTAI SHUODING TRADING CO.,LTD engineers each roll for high load, high temperature, and high line-speed environments typical of modern gigafactory lines.

Technical highlights commonly requested by battery OEMs include mirror-grade surfaces (low Ra to stabilize coating morphology), ultra-low TIR for uniform nip pressure, robust core materials (alloy/forged steel or carbide solutions), hardened surfaces for wear resistance, and internal channel designs for efficient thermal regulation. For calendering mills, matched sets of work rolls and rolling intermediate rolls ensure crown control and stable shape under dynamic loads, minimizing edge waviness and local over-densification. Backed by rigorous grinding and balancing processes, XINGTAI SHUODING’s roll portfolio supports consistent electrode density and improved coating adhesion, helping production teams hit tighter spec windows with fewer changeovers.

Benefits & Use Cases of rolling roller,roller,roller manufacturer,roll supplier,roll,work rolls,rolling intermediate roll in Lithium battery production equipment

Across the lithium battery production line, the right roller selection delivers measurable gains. In electrode calendering, precision work rolls stabilize porosity and calender gap, boosting energy density and cycle life. In coating and drying sections, guide and transfer rolls with anti-stick surface treatments reduce picking and streaking. On slitting and rewinding, balanced rolls protect edge quality and prevent telescoping. For 4-Hi/6-Hi stacks, the rolling intermediate roll manages load distribution, extending the life of the work rolls and preserving profile accuracy at higher line speeds.

XINGTAI SHUODING TRADING CO.,LTD differentiates as both a roller manufacturer and a responsive roll supplier with customization capabilities: tailored diameters/face lengths, selectable surface hardness and finishes, chrome or specialty coatings, oil/water thermal channels, and ISO-class dynamic balancing. These features translate into cleaner surfaces, reduced scrap, and stable uptime under aggressive solvent- or water-based chemistries. Whether you need a primary calender roll, a precision roll for separator lines, or replacement rolls for an existing mill, SHUODING’s engineering support ensures the roll is optimized for your substrate, binder system, and throughput targets.

Cost, Maintenance & User Experience

Total cost of ownership for a roll hinges on durability, surface stability, and serviceability. SHUODING’s approach extends roll life through high-grade materials, deep-case hardening options, and precision finishing that resists micro-scratches and corrosion. Lower wear keeps roughness stable, maintaining electrode uniformity longer and reducing regrind frequency. Users often see value through higher first-pass yield, fewer unplanned stops, and shortened recipe changeovers—key drivers for ROI in high-throughput gigafactory environments.

From a maintenance perspective, best practices include scheduled TIR and surface checks, clean-room compatible handling, solvent-safe cleaning protocols, and planned regrinding to restore mirror finish. XINGTAI SHUODING TRADING CO.,LTD supports service cycles with inspection guidance, quick-turn refurbishment, and fast replacement of critical work rolls and rolling intermediate rolls to minimize downtime. Customer feedback highlights consistent nip stability, smooth web transport, and improved coating fidelity, especially when upgrading from generic rollers to purpose-built calender rolls sourced from a specialist roller manufacturer.

Sustainability & Market Trends in new energy industry

EV and ESS demand are pushing electrode lines to run faster, thinner, and more precisely—while meeting increasingly stringent ESG targets. High-quality rolls directly support sustainability by reducing scrap, extending tool life, and improving energy efficiency via optimized thermal management and lower drag. As regulations and OEM scorecards emphasize safer solvents, water-based binders, and recyclability, roller design must resist chemical attack and maintain finish across a wider process window.

XINGTAI SHUODING TRADING CO.,LTD aligns with these trends through longer-life roll designs, regrind/refurbish programs that cut material waste, and traceable supply practices. Looking ahead, the transition to advanced electrode architectures—including high-loading cathodes, silicon-rich anodes, and pilot-scale dry electrode processes—will demand even tighter control of nip pressure and surface finish. By partnering with a forward-looking roll supplier capable of rapid customization and rigorous QA, manufacturers can future-proof their lines while meeting sustainability commitments.

Conclusion on rolling roller,roller,roller manufacturer,roll supplier,roll,work rolls,rolling intermediate roll from XINGTAI SHUODING TRADING CO.,LTD

For lithium battery production equipment, selecting the right rolling roller—whether as work rolls in calender mills or a rolling intermediate roll for shape control—is essential to yield, consistency, and cost. As an experienced roller manufacturer and dependable roll supplier, XINGTAI SHUODING TRADING CO.,LTD delivers precision, durability, and rapid service that B2B decision makers can trust. Contact us: email: sdtrading0927@126.com. Visit our website: https://www.xtshuoding.com

Share

-

Lithium Battery Welding Machine | High-Precision, Fast, SafeNewsNov.17,2025

-

Aluminium Guide Roller | Anodized, Lightweight, Low-NoiseNewsNov.17,2025

-

Tofu Cat Litter Bulk – Eco, Low-Dust, Fast Clumping SupplyNewsNov.17,2025

-

Equipment for Lithium Cell Assembly | Automated & PreciseNewsNov.10,2025

-

Square File Tool – Precision Cut, Hardened Steel, VersatileNewsNov.10,2025

-

Lithium Ion Battery Assembly Machine | Automated, High-SpeedNewsNov.10,2025