electrical rubber sealing strip

Understanding Electrical Rubber Sealing Strips A Comprehensive Overview

In the world of electrical engineering and manufacturing, maintaining the integrity of electrical connections and components is crucial. One of the key components facilitating this integrity is the electrical rubber sealing strip. These strips are essential in protecting electrical systems from environmental factors and ensuring reliable operation.

What Are Electrical Rubber Sealing Strips?

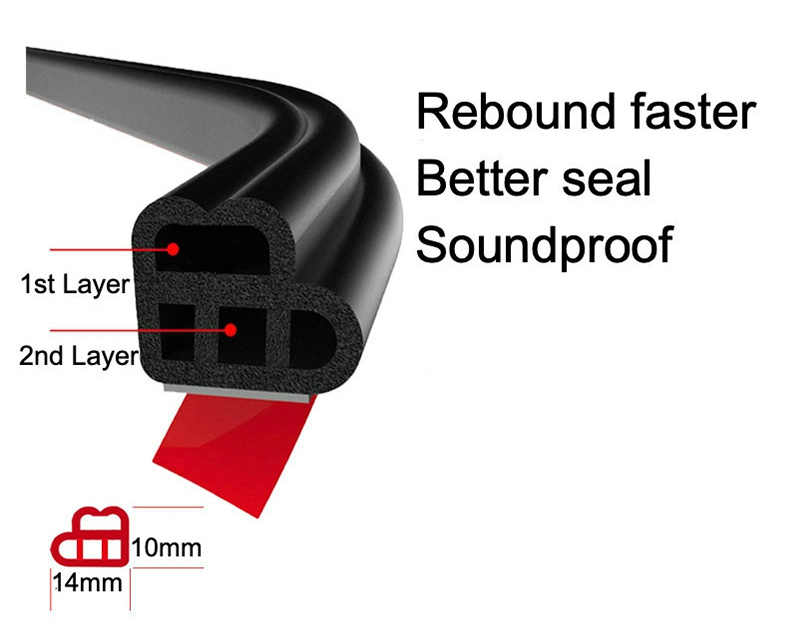

Electrical rubber sealing strips are flexible, durable materials made from various types of rubber, including silicone, EPDM (ethylene propylene diene monomer), and neoprene. They are specifically designed to form a barrier against moisture, dust, and other external elements. Their primary function is to seal joints, gaps, and connections in electrical enclosures, ensuring that sensitive components are protected from the outside environment.

Importance in Electrical Applications

The importance of these sealing strips cannot be overstated. In many electrical applications, exposure to water, dust, and other contaminants can lead to malfunctions, corrosion, and eventual failure of the components. Electrical rubber sealing strips act as a first line of defense, keeping the internal environment of electrical devices safe and secure. This becomes particularly critical in sectors such as automotive, aerospace, telecommunications, and consumer electronics, where equipment is often exposed to harsh environments.

Key Features

1. Weather Resistance Electrical rubber sealing strips are designed to withstand extreme weather conditions, including high temperatures, UV radiation, and harsh chemicals. This makes them suitable for outdoor electrical installations, such as streetlights and utility boxes.

2. Flexibility These strips are incredibly flexible, allowing them to conform to various shapes and sizes. This adaptability is crucial when sealing irregular or non-uniform surfaces.

3. Durability Made from high-quality rubber materials, these sealing strips offer excellent durability and longevity. They can maintain their sealing properties over extended periods, reducing the need for frequent replacements.

electrical rubber sealing strip

4. Electrical Insulation Certain rubber materials used in these sealing strips provide excellent electrical insulation, further protecting electrical components from short circuits and other electrical failures.

Types of Electrical Rubber Sealing Strips

Several types of electrical rubber sealing strips are available in the market, each designed for specific applications

- Self-Adhesive Strips These strips come with an adhesive backing, making them easy to apply without the need for additional adhesives. They are ideal for quick installations and repairs.

- Extruded Profiles Many sealing strips are extruded into specific shapes and sizes, allowing for a tailored fit in various applications, such as cable entries and mounting plates.

- Molded Seals For applications requiring precision, molded seals provide a custom fit and are often used in high-performance environments.

Installation and Maintenance

Proper installation and maintenance of electrical rubber sealing strips are vital for their effectiveness. When installing, it’s essential to ensure that the surfaces are clean and free of debris, as contaminants can impede the sealing performance. Additionally, regular inspections should be conducted to check for wear and tear, as damaged or degraded sealing strips may need replacement to maintain protection.

Conclusion

Electrical rubber sealing strips play a critical role in safeguarding electrical systems from environmental threats. Their unique properties—such as weather resistance, flexibility, and electrical insulation—make them indispensable in a wide variety of applications. Understanding the importance of these sealing strips and ensuring their proper installation and maintenance can significantly enhance the reliability and longevity of electrical components. As technology continues to advance and environments become more demanding, the role of electrical rubber sealing strips will only become more significant, ensuring that we can depend on our electrical systems to function safely and efficiently.

Share

-

The Best Lubricants for Aluminum Roller GuidesNewsJul.23,2025

-

Slitting Machine Applications in the Packaging IndustryNewsJul.23,2025

-

Rolling Roller Balancing Techniques for Smooth OperationNewsJul.23,2025

-

How To Optimize An EV Battery Assembly LineNewsJul.23,2025

-

Energy Efficiency in Modern Battery Formation EquipmentNewsJul.23,2025

-

Automation Trends in Pouch Cell Assembly EquipmentNewsJul.23,2025