Square File Tool – Hardened Steel, Precision Second Cut

Square File Products: A Practical Insider’s Guide

If you’re choosing a square file tool for metal, wood, or even post-processing 3D prints, here’s the honest take from the shop floor. Origin matters, and these come from Room 1410, No. 119 Zhongxing East Street, Xiangdu District, Xingtai City, Hebei Province, China—an area that’s been making cutting tools for ages. The defining trait: four equal faces with a “second cut” tooth pattern that bites fast and leaves a controllable finish. Many customers say it’s the go-to when turning a round pilot hole into a clean square opening.

What’s Trending (and why hand files are back)

Surprisingly, hand tools are having a mini-renaissance. Fabricators use CNC for bulk removal, then reach for a square file tool to deburr, tweak tolerances, and square corners that machines avoid. DIYers love the control; maintenance techs like the portability. Sustainability plays a part too—repair and rework instead of replace.

Core Specifications (typical, real-world use may vary)

| Material | High-carbon tool steel (≈T12/W1) or Cr-V alloy for toughness |

| Hardness | HRC 60–64 after heat treatment (ISO 234-1 guidance) |

| Cut/Coarseness | Second cut (medium-fast stock removal) |

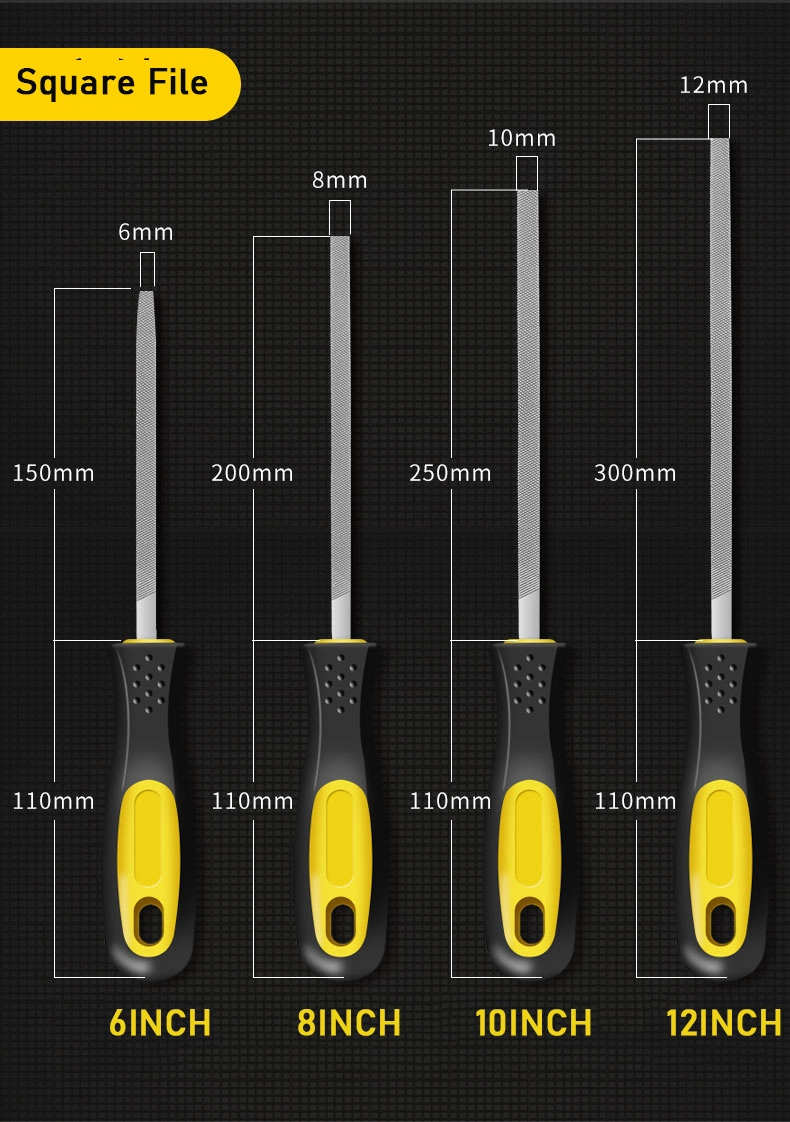

| Lengths | 100–300 mm overall (≈4–12 in) |

| Tip/Edges | True-square corners for internal corners and keyways |

| Surface Finish | Anti-rust oil, optional black oxide |

Process Flow and Quality

Materials are forged or blanked, teeth are milled or machine-cut, then hardened and tempered for the sweet spot between bite and toughness. Testing includes Rockwell hardness (HRC), tooth uniformity checks, and bend/impact sampling. Reference standards include ISO 234-1 for files and DIN 7261 geometry. Typical service life? Around 3–12 months of shop use, depending on abrasiveness of workpiece (mild steel vs. stainless), pressure, and cleaning habits (a file card helps a lot).

- Industries: metal fabrication, locksmithing, toolroom, woodworking, MRO, and prototyping.

- Methods: push strokes with even pressure; rotate faces to keep corners sharp.

- Safety: secure workpiece in a vise; add a handle to the tang—seriously, don’t skip it.

Quick Vendor Snapshot

| Vendor | Strengths | Notes |

|---|---|---|

| XT Shuoding (Hebei, China) | Stable HRC; consistent second-cut teeth; OEM customization | MOQ-friendly, ISO 9001 reported |

| Brand B (EU) | Premium finish, long wear on stainless | Higher price; limited custom sizes |

| Brand C (US/Global) | Widely available; good QC track record | Lead times vary by region |

Customization and Real-World Results

Options usually include lengths, handle type, tooth pattern, black oxide vs. polished, and private labeling. One metal shop reported a 27% faster square-hole finishing time vs. a general-purpose file; stock removal on mild steel hit ≈90–120 mm³/min with a square file tool, verified on a simple weight-loss bench test. Edge rounding stayed under 0.15 mm after 2,000 strokes—respectable for second cut.

Where it Shines

- Squaring round pilot holes for panels and keyways

- Deburring laser-cut corners and die edges

- Fitting hardware (think: square carriage bolts) and mortise clean-up in wood

- Touch-ups on 3D-printed parts where corners need definition

Users frequently mention clean bite with minimal chatter—provided they keep the square file tool clean and avoid clogging on soft alloys. Certification claims to look for: ISO 9001 quality systems, RoHS material compliance, and hardness logs traceable to batch numbers.

Final Take

Honestly, it’s not glamorous, but a good square file tool is a small investment that saves rework time. If you need consistent corners and quick stock removal, second cut is a smart default. And yes—use a handle.

Authoritative citations

- ISO 234-1:2015 — Files and rasps — Part 1: General requirements.

- DIN 7261 — Hand files, dimensions and technical conditions (commonly referenced in EU tooling).

- ANSI/ASME B94.6 — Hand Files (industry reference for geometry and performance expectations).

Share

-

Lithium Battery Welding Machine | High-Precision, Fast, SafeNewsNov.17,2025

-

Aluminium Guide Roller | Anodized, Lightweight, Low-NoiseNewsNov.17,2025

-

Tofu Cat Litter Bulk – Eco, Low-Dust, Fast Clumping SupplyNewsNov.17,2025

-

Equipment for Lithium Cell Assembly | Automated & PreciseNewsNov.10,2025

-

Square File Tool – Precision Cut, Hardened Steel, VersatileNewsNov.10,2025

-

Lithium Ion Battery Assembly Machine | Automated, High-SpeedNewsNov.10,2025