Rubber Seals for Roll-Up Doors from Leading Manufacturers and Suppliers

The Importance of Roll-Up Door Rubber Seals An Overview of Factories and Their Innovations

Roll-up doors are a crucial component in various industries, including warehouses, garages, and emergency service facilities. Offering convenience and security, these doors require reliable sealing solutions to maintain efficiency and ensure safety. One of the most essential parts of a roll-up door is its rubber seal, which serves not only to enhance thermal insulation but also to protect against dust, debris, and pests. The factories producing these rubber seals play a pivotal role in the functionality and longevity of roll-up doors.

Understanding Rubber Seals in Roll-Up Doors

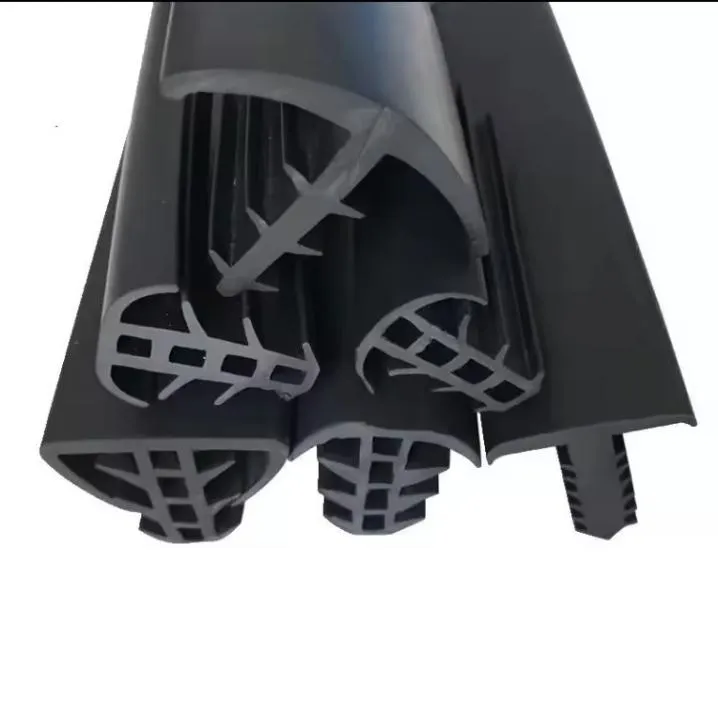

Rubber seals for roll-up doors are designed to provide a tight barrier between the door and the floor or surrounding frame. This ensures that no gaps are left that can compromise the environment's integrity. High-quality rubber seals are vital in preventing wind, rain, and snow from entering the premises, which can be especially important for temperature-sensitive goods stored in warehouses. Additionally, these seals often contribute to energy efficiency by minimizing heating and cooling costs.

Production Processes in Rubber Seal Factories

Factories specializing in the manufacturing of rubber seals employ advanced technologies and processes to produce durable and effective products. The production begins with the selection of high-grade rubber materials, which can include EPDM (ethylene propylene diene monomer), neoprene, or silicone-based compounds. These materials are chosen for their resilience to environmental stressors, including UV light and extreme temperatures.

Once the raw materials are sourced, they undergo a process of mixing and formulation. This is critical because the properties of rubber can be altered by the addition of various chemical compounds, enhancing attributes like flexibility and longevity. The next step involves molding the rubber into specific shapes that match the dimensions and requirements of different roll-up door designs.

Cutting-edge factories often utilize computer numerically controlled (CNC) machines for precision cutting and shaping of the rubber seals. This technology allows for minimal wastage and maximizes consistency across products. Quality control is meticulously maintained at various stages of production, with inspections featuring dimensional checks, flexibility tests, and assessments of resistance to environmental factors.

roll up door rubber seal factories

Innovations in Rubber Seal Technology

With the increasing demand for resilience and adaptability in industrial applications, rubber seal manufacturers are constantly innovating. One notable development is the use of advanced rubber compounds that include additives to enhance fire resistance and chemical stability. Such innovations are crucial for industries where safety and product protection are paramount.

Additionally, smart technology is beginning to influence the production of roll-up door rubber seals. Factories are exploring ways to incorporate sensors within rubber seals that monitor door performance and alert facility managers about maintenance requirements. This predictive approach can significantly reduce downtime and enhance overall operational efficiency.

Market Demand and Global Reach

The market for roll-up door rubber seals is witnessing substantial growth, driven by the expansion of logistics, construction, and manufacturing sectors. As businesses prioritize efficiency and security, the need for high-quality sealing solutions continues to rise. Major manufacturers are not only catering to local markets but are increasingly expanding their reach globally, ensuring that industries around the world benefit from advanced sealing technologies.

Countries like the United States, China, and Germany are leading producers of rubber seals, supported by a robust infrastructure and a commitment to research and development. The competition among manufacturers also incentivizes continual improvement in product quality and customer service, leading to better outcomes for end-users.

Conclusion

The role of roll-up door rubber seal factories is integral to the functionality of roll-up doors across various sectors. Through the use of high-quality materials, innovative manufacturing processes, and the adoption of new technologies, these factories ensure that rubber seals meet the demands of modern industries. As market needs evolve and technology advances, we can expect to see even more breakthroughs in the design and performance of rubber seals, reinforcing their importance in maintaining secure, efficient, and environmentally friendly operations. As businesses look to the future, investing in quality seals will continue to be paramount for operational success and sustainability.

Share

-

The Best Lubricants for Aluminum Roller GuidesNewsJul.23,2025

-

Slitting Machine Applications in the Packaging IndustryNewsJul.23,2025

-

Rolling Roller Balancing Techniques for Smooth OperationNewsJul.23,2025

-

How To Optimize An EV Battery Assembly LineNewsJul.23,2025

-

Energy Efficiency in Modern Battery Formation EquipmentNewsJul.23,2025

-

Automation Trends in Pouch Cell Assembly EquipmentNewsJul.23,2025