Need Pouch Cell Assembly Equipment for Faster, Higher Yield?

Inside the Modern Pouch Cell Line: What Really Matters in 2025

If you're weighing up pouch cell assembly equipment for a new line or a scale-up, you’ve probably noticed how quickly the goalposts move. In fact, a few years ago, 80% OEE felt ambitious; now buyers are casually asking about high-90s and MES-native traceability. To be honest, it’s exciting—and a little exhausting. Here’s a practical look at the 100MWH/1GWh LFP/NMC/LTO Turnkey Pouch Cell Manufacturing Line (Model SD-PCPL) coming out of Room 1410, No. 119 Zhongxing East Street, Xiangdu District, Xingtai City, Hebei, China—plus how it stacks up in the real world.

Industry trends I’m seeing on the shop floor

- Rapid ramp: pilot-to-0.5GWh in under 6 months is no longer rare.

- Cross-chemistry flexibility: LFP for ESS, NMC for EV, LTO for high-C power tools.

- Dry-room discipline: ISO 7/8 with dew point around ≤ −40°C is table stakes.

- Inline metrology: vision + laser thickness, OCV/ACIR at multiple gates.

- Traceability-by-design: native MES, barcode/QR genealogy, and SPC dashboards.

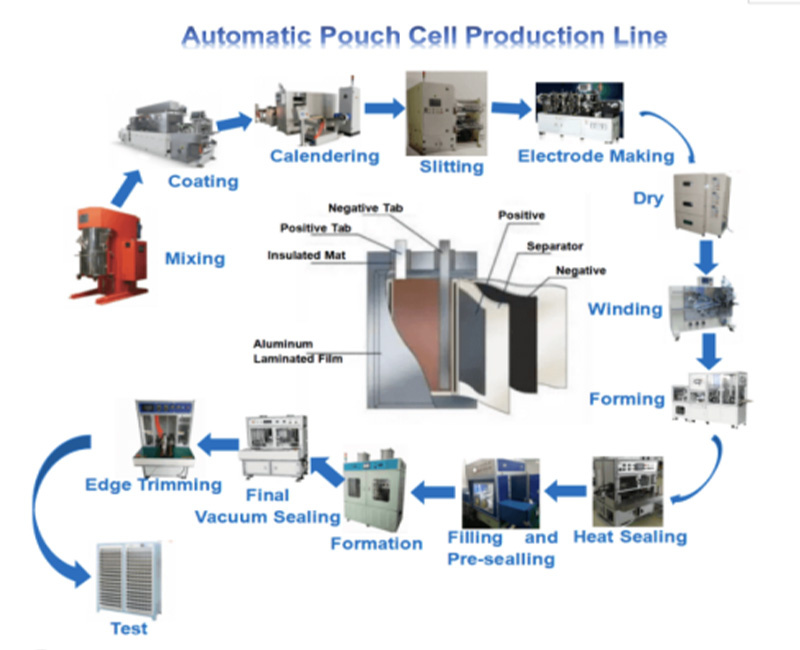

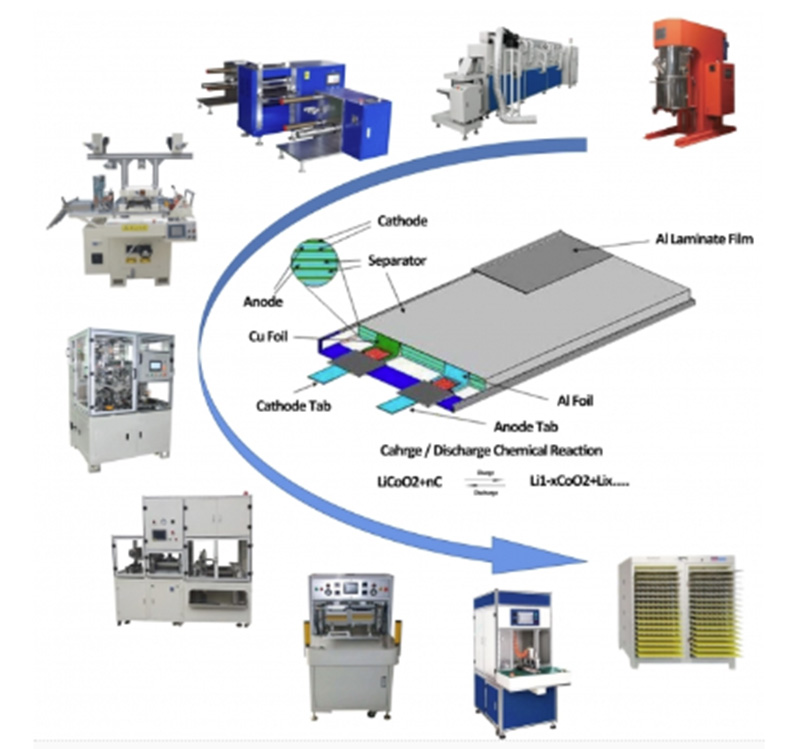

Process flow, materials, and methods (short version)

Coating (cathode/anode for LFP/NMC/LTO) → Drying → Calendering → Slitting → Z‑fold stacking or lamination → Pouch forming → Tab welding (Al/Cu; ultrasonic/laser) → Vacuum electrolyte filling (EC/EMC/DEC systems; typical dosing accuracy ±0.01–0.02 g) → Pre-seal → Formation (CC/CV, temperature‑controlled) → Aging/rest → Degassing → Final seal → EOL testing (OCV, ACIR, leak, capacity grading). Service life targets: LFP ≈ 3000+ cycles @ 80% DoD (real-world may vary), NMC ≈ 1000–2000, LTO can exceed 5000 with excellent power density.

Product snapshot: SD-PCPL Turnkey Line

| Parameter | Spec (≈, may vary) |

|---|---|

| Capacity window | 100 MWh–1 GWh per year |

| Chemistry | LFP / NMC / LTO |

| Stacking speed | Up to ≈ 0.6–1.0 s/layer (cell size dependent) |

| Yield (ramp target) | ≥ 95% after stabilization |

| Electrolyte dosing | ±0.01–0.02 g, vacuum fill |

| Environment | ISO 7/8 dry room, dew point ≤ −40°C |

| Traceability | MES-ready, full genealogy |

| Compliance | CE Certified; supports IEC 62133, UN 38.3 EOL tests |

| Model / Warranty | SD-PCPL / One-year limited, lifetime support |

| Origin / Port | Hebei, China / TIANJIN Port |

Example FAT test data (recent project): OCV repeatability ±2 mV, ACIR CV ≈ 1.5%, pouch leak rate ≤ 1×10⁻³ mbar·L/s, sample capacity variation ≤ 2.0% after formation. Customers tell me the SPC charts calm auditors—surprisingly, that matters more than marketing slides.

Vendor comparison (quick, honest take)

| Item | Shuoding SD‑PCPL | Generic Import Line | In‑house Retrofit |

|---|---|---|---|

| Capacity | 100 MWh–1 GWh | ≈ 50–300 MWh | Varies |

| CE / Standards | CE; IEC/UN test gates | Partial | Depends |

| MES integration | Native APIs | Add‑on | Custom dev |

| Lead time | Around 12–20 weeks | 20–32 weeks | Uncertain |

| Commissioning | 4–8 weeks | 8–12 weeks | Variable |

Applications, customization, and feedback

- Use cases: EV modules, stationary ESS, telecom backup, wearables (thin cells).

- Customization: die sets for pouch sizes, Z‑fold head options, ultrasonic/laser tab welders, electrolyte recipes, inline X‑ray or leak-test upgrades.

- Many customers say the inline grading + MES genealogy cuts RMA headaches by half—anecdotal, but consistent.

Case study (EU ESS maker): ramped to 0.2 GWh/year in 120 days; yield rose from 94.1% to 97.8% after DOE tweaks to calender pressure and fill vacuum. Not perfect, but solid.

Why this pouch cell assembly equipment is compelling

The mix of CE certification, lifetime support, and pragmatic throughput—plus shipping via TIANJIN Port—makes it a realistic choice for teams that need to scale without burning a year on debug. And yes, the address is in Hebei, but spares logistics have been surprisingly responsive. If you’re building against IEC 62133, UN 38.3, and aiming at IATF 16949 discipline, it hits the right notes.

Citations

- IEC 62133-2: Secondary cells and batteries containing alkaline or other non-acid electrolytes. https://webstore.iec.ch

- UN Manual of Tests and Criteria, Section 38.3 (UN 38.3). https://unece.org

- IEC 62660 series: Secondary lithium-ion cells for EV. https://webstore.iec.ch

- ISO 14644 Cleanrooms and associated controlled environments. https://www.iso.org

- IATF 16949: Automotive Quality Management. https://www.iatfglobaloversight.org

Share

-

Lithium Battery Welding Machine | High-Precision, Fast, SafeNewsNov.17,2025

-

Aluminium Guide Roller | Anodized, Lightweight, Low-NoiseNewsNov.17,2025

-

Tofu Cat Litter Bulk – Eco, Low-Dust, Fast Clumping SupplyNewsNov.17,2025

-

Equipment for Lithium Cell Assembly | Automated & PreciseNewsNov.10,2025

-

Square File Tool – Precision Cut, Hardened Steel, VersatileNewsNov.10,2025

-

Lithium Ion Battery Assembly Machine | Automated, High-SpeedNewsNov.10,2025