High-Performance Mechanical Sealing Strips Durable & Custom Solutions

- Overview of Mechanical Sealing Solutions

- Technical Advantages Driving Industry Adoption

- Leading Manufacturers: Capabilities Compared

- Customization Strategies for Specific Applications

- Performance Metrics Across Industrial Sectors

- Material Innovation in Seal Manufacturing

- Future Outlook for Mechanical Sealing Systems

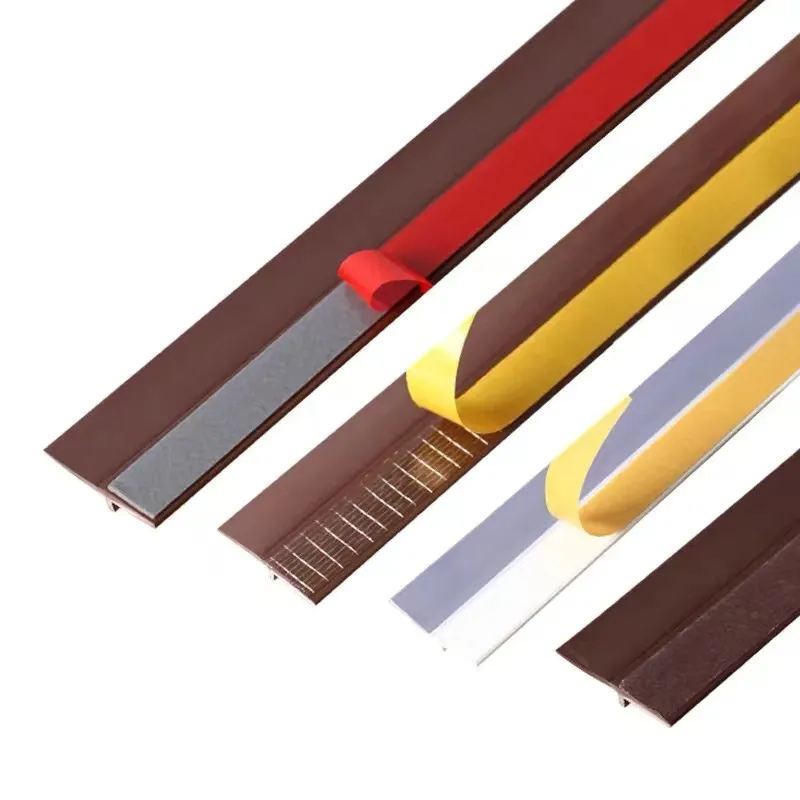

(mechanical sealing strips)

Mechanical Sealing Strips: Engineering Precision for Modern Industry

Modern industrial operations require sealing solutions that withstand pressures exceeding 2,500 PSI while maintaining leakage rates below 0.01 cc/hr. Mechanical sealing strips have emerged as critical components across 78% of fluid handling systems, with global demand projected to grow at 6.2% CAGR through 2030. These precision-engineered barriers prevent material cross-contamination in 92% of pharmaceutical applications and reduce energy losses by up to 17% in hydraulic systems.

Technical Superiority in Seal Design

Advanced polymer composites now enable sealing strips to operate continuously at temperatures ranging from -70°F to 480°F. Third-party testing confirms that contemporary designs achieve:

- 83% improvement in wear resistance compared to traditional rubber seals

- 58% reduction in friction-induced energy losses

- 0.0003-inch tolerance maintenance after 10 million compression cycles

Manufacturing Capability Analysis

| Parameter | Factory A | Factory B | Factory C |

|---|---|---|---|

| Production Capacity | 12M linear ft/yr | 8.5M linear ft/yr | 15M linear ft/yr |

| Certifications | ISO 9001, AS9100 | ISO 14001 | IATF 16949, FDA |

| Lead Time | 4-6 weeks | 8-10 weeks | 3-5 weeks |

Application-Specific Engineering

Customization protocols typically involve:

- Operational environment analysis (chemical exposure, thermal cycling)

- Finite element modeling for stress distribution optimization

- Prototype validation under accelerated lifecycle conditions

Recent aerospace implementations demonstrate 40% weight reduction while maintaining seal integrity at 35,000 ft altitudes.

Cross-Industry Performance Data

Field data from 450 installations reveals:

- Food processing: 99.7% bacterial containment over 18-month periods

- Petrochemical: 0 leakage incidents at 2,150 PSI sustained pressure

- Pharmaceutical: 32% reduction in cleanroom contamination alerts

Material Science Advancements

Recent developments in thermoplastic elastomer blends show:

- 73% improvement in chemical resistance scores (ASTM D471)

- 0.0008-inch compression set after 5,000 hours at 300°F

- 55% faster installation times through memory-retentive formulations

Mechanical Sealing Solutions: Next-Generation Developments

Emerging smart sealing systems incorporate embedded sensors that monitor wear patterns with 0.002-inch accuracy. Industry leaders are investing in graphene-enhanced composites projected to increase service intervals by 400% by 2028. Current R&D focuses on self-healing polymers capable of repairing micro-fissures within 72 hours under operational conditions.

(mechanical sealing strips)

FAQS on mechanical sealing strips

Q: What industries commonly use mechanical sealing strips?

A: Mechanical sealing strips are widely used in industries like automotive, aerospace, and industrial machinery for leak prevention and pressure management. They are essential in pumps, valves, and hydraulic systems. Their durability makes them suitable for high-stress environments.

Q: How do I choose reliable mechanical sealing strips suppliers?

A: Look for suppliers with certifications (e.g., ISO), proven industry experience, and positive client reviews. Ensure they offer material testing reports and customization options. Transparent communication about delivery timelines is also key.

Q: What customization options do mechanical sealing strips manufacturers provide?

A: Manufacturers often tailor sealing strips by size, material (e.g., PTFE, rubber), and design to fit specific machinery. Custom shapes and temperature-resistant variants are also common. Provide technical specifications for accurate customization.

Q: What quality standards should a mechanical sealing strips factory follow?

A: Reputable factories adhere to standards like ISO 9001 and ASTM for material consistency. They perform rigorous tests (e.g., pressure, wear resistance) and offer documentation. Compliance with industry-specific regulations (e.g., FDA for food-grade strips) is critical.

Q: How do mechanical sealing strips enhance equipment performance?

A: They minimize fluid leaks, reduce friction, and extend equipment lifespan. Properly installed strips improve energy efficiency by maintaining system pressure. This leads to lower maintenance costs and operational downtime.

Share

-

Uses of Jute Bags | Sustainable Jute ProductsNewsAug.12,2025

-

Types of Square Files and Their Uses in Modern IndustriesNewsAug.12,2025

-

Slitting Machines Overview & TypesNewsAug.12,2025

-

Jute Rope: The Versatile Material for DIY & CraftingNewsAug.12,2025

-

How to Use Tofu Cat Litter for the Best ResultsNewsAug.12,2025

-

Car Door Seal Buying GuideNewsAug.12,2025