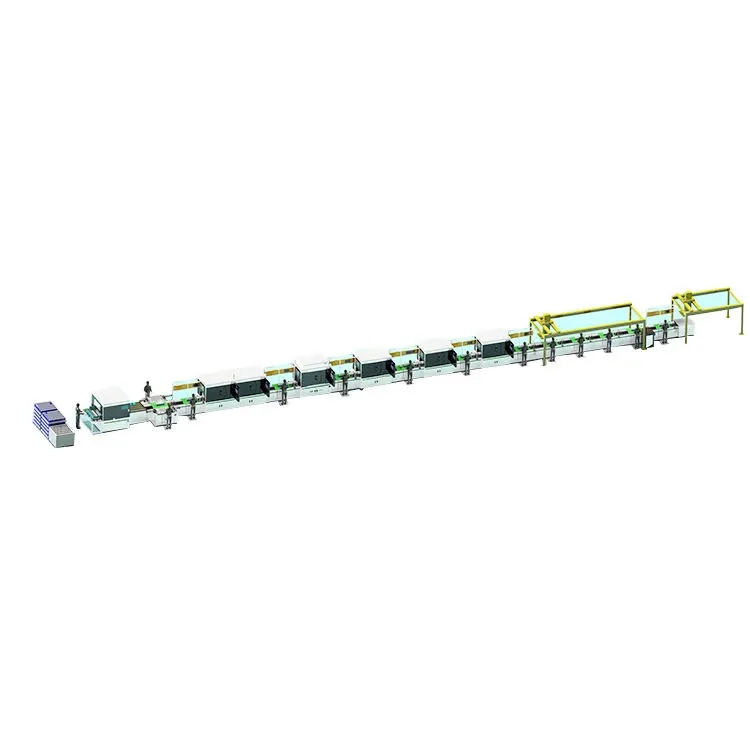

Industrial and Commercial Energy Storage Module Laser Production Line

1: Application:

Industrial and commercial energy storage systems, battery module production

2: Technical Features:

- High degree of automation, strong compatibility, high precision, and fast speed.

- Automated production, reduced manual positions, improved overall production efficiency.

- Customizable automated production line solutions according to customer needs.

- Adaptable to specific customer requirements.

3: Technical Parameters:

- Equipment Efficiency: ≥ 12PPM.

- Single Machine Qualification Rate: ≥ 99%.

- Overall Dimensions: 46000mm×4700mm×2852mm.

- Power Supply: 220V, 50Hz.

- Power: 2000W.

- Power Capacity: >80Kw.

- Air Pressure Requirement: 260L/min, 0.5-0.8MPa.

- Dimension(L*W*H) 46000mm *4700mm*2852mm.

- Voltage 220V.

- Power 2000W.

4: Introduction:

Introduction to Line Body

This automated assembly line is mainly divided into three parts:

1、 Cell sorting section: Manually use a forklift to transport the fully loaded battery cell material frame from the battery buffer area to the six axis robot loading position. The six axis robot grabs 5 battery cells for loading at once,

The equipment scans the code of the battery cells, performs OCV testing and sorting (1 OK level and 1 NG level), automatically applies and tears the adhesive at the adhesive bonding and inspection station, and applies the epoxy board at the end plate station.

2、 Module line segment: the equipment adopts a six axis robot to take materials, stack the electric cores, and the six axis robot takes materials into the binding and binding position, and then discharges them to the double speed chain; The workstations on the double speed chain include: laser engraving scanning, AI polarity detection and pole addressing, pole cleaning, manual installation of connecting pieces, laser welding, cleaning workstations, weld scar detection, installation of collection harnesses, collection harness welding, module shell insertion, DCIR detection, manual installation of cover plates, loading and unloading of swing arms, and other processes.

3、 PACK assembly section: shell online, liquid cooled plate airtightness inspection, liquid cooled plate gluing, module scanning and fixing into the box, voltage acquisition line installation, lifting into the shell, BMS installation, component installation, panel installation, power harness installation, manual scanning, BMS testing, E0L testing cover, airtightness testing, gantry crane finished product offline;

Equipment overall performance requirements:

High degree of automation, high compatibility, high accuracy, and fast speed.

5: Product technical characteristics:

A. High degree of automation, high compatibility, high accuracy, and fast speed.

B. Realize automated production, reduce the number of manual positions, and achieve high overall production efficiency. C. We can customize automated production line solutions according to customer needs.

D. Customizable according to specific customer needs.

6: Product technical parameters:

- Equipment Name: Industrial and Commercial Energy Storage Module Laser Production Line.

- Equipment efficiency square production line ≥ 12PPM.

- Single machine qualification rate ≥ 99%.

- Layout and land occupation note: Overall dimensions of the line: (approximately) Length: Front section 46000mm Width: 4700mm Height: 2852mm.

- Note: Overall dimensions of the entire line: (approximately) Length: rear section 32000mm Width: 2750mm Height: 2900mm.

- Energy demand: Power supply of 380V ± 5%, 50Hz, with a capacity greater than 80Kw. Instrument air pressure 260L/min, 0.5~0.8MPa.

7: Product Process Flow Diagram:

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

News