Laser Welding Machine for Energy Storage Battery, Electric Motorcycle Battery

1: Application:

This equipment is suitable for ultrasonic semi-automatic welding for stacking/winding cells of soft package power battery, with cell tab pre-welding, prewelding fixed-length cutting, Tab main welding, welding surface burr pressing and vacuuming, welding surface sticking protective tape,cell flat pressing shortcircuit test of pre-weiding/post-welding , manual loading and unloading and manual transfer function, etc. It is used to

1: Cylindrical Cell Production Line;

2: Cylindrical Cell Lab Machine;

3: Pouch Cell Production Line;

4: Pouch Cell Laboratory Machine;

6: 18650 26650 21700 32650 Cylindrical Cell Laboratory;

7:1GWh EV Car Battery LFP/NMC/LTO 30Ah 50Ah 100Ah 200Ah Prismatic Cell Aluminium;

Why Choose Xingtai shuoding trading Co., Ltd?

- **Innovative Technology**: Our production lines incorporate the latest technological advancements to ensure optimal performance and reliability.

- **Customization**: We understand that each business has unique requirements. Our team can customize solutions to meet your specific production needs.

- **Support & Maintenance**: We provide comprehensive support and maintenance services to ensure your production lines operate smoothly.

- **Cost-Effectiveness**: Our solutions are designed to deliver maximum value while keeping your investments optimal.

- **Sustainability**: Our lithium battery production lines emphasize sustainability, helping you reduce your carbon footprint and contribute to a greener planet.

2: Features:

1 Fixtures are configured in the process of manually transferring the cells to prevent the dislocation of the electrode sheets.

2 Negative pressure vacuuming function is equipped during pre-welding, cutting, main welding and burr pressing of tabs.

3 Ultrasonic welding is firm, no virtual welding, no vibration powder, no damage to the diaphragm, no melting insulating glue, no shock cracking foil.

4 It is replaceable and compatible with multi-type battery tab welding, compatible with cells with same side/different side tabs.

5 A variety of taping way on the welding surface can be chosen according to customer needs (flat taping, L-type taping, Z-type taping).

6 It is flexible to simplify or enrich configuration in order to minimize cost.

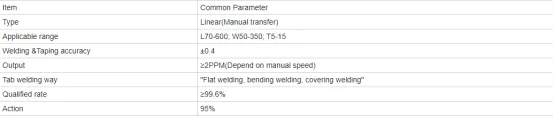

3: Parameters:

ニュース