2月 . 02 , 2025 03:13

Back to list

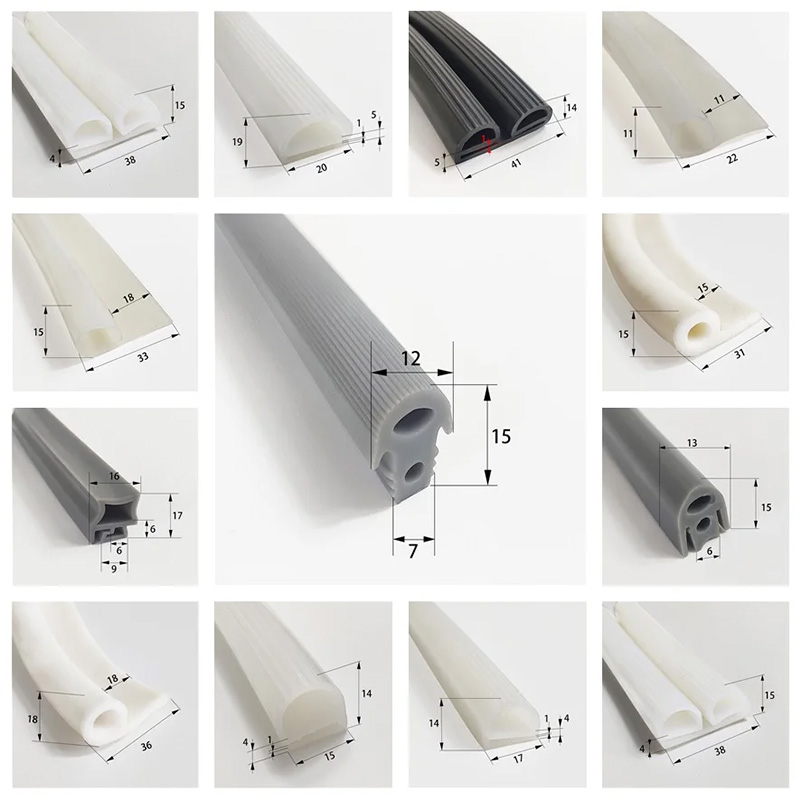

hangar door rubber seals

Industrial rubber door seals, a critical component in various sectors, ensure optimal performance by preventing unwanted air and moisture infiltration. The importance of these seals stretches across multiple industries, including automotive, construction, and manufacturing, each demanding robust and reliable sealing solutions.

Furthermore, the continual innovation in seal technology reflects the authoritative expertise of industry leaders dedicated to meeting the evolving needs of their clientele. Manufacturers invest significantly in R&D to enhance seal performance, embracing cutting-edge technologies like 3D modeling and advanced composite material development. This commitment to innovation not only enhances the durability and functionality of rubber door seals but also aligns with the growing emphasis on sustainability, as manufacturers strive to minimize environmental impact. Establishing trustworthiness remains paramount in the industrial rubber door seal industry. Leading manufacturers offer comprehensive warranties, underlining their confidence in product longevity and performance. Certifications, such as ISO standards, further assure customers of the product's quality and reliability. These certifications are a testament to the rigorous testing and quality control processes that the seals undergo before reaching the market. For customers seeking to purchase industrial rubber door seals, making informed decisions necessitates attention to these pivotal factors. Ensuring the compatibility of the rubber material with the intended environmental conditions is crucial. Collaborating with reputable manufacturers who disclose detailed product specifications and performance data can safeguard against inferior products that may lead to costly repairs or replacements. In conclusion, industrial rubber door seals stand as essential components across various industries. Their role in enhancing energy efficiency, providing environmental protection, and sustaining operational stability cannot be overstated. Through continuous innovation, stringent quality control, and a commitment to addressing customer needs, the industry exemplifies the highest standards of expertise and trustworthiness, ensuring that these unobtrusive yet vital elements continue to support our modern industrial framework effectively.

Furthermore, the continual innovation in seal technology reflects the authoritative expertise of industry leaders dedicated to meeting the evolving needs of their clientele. Manufacturers invest significantly in R&D to enhance seal performance, embracing cutting-edge technologies like 3D modeling and advanced composite material development. This commitment to innovation not only enhances the durability and functionality of rubber door seals but also aligns with the growing emphasis on sustainability, as manufacturers strive to minimize environmental impact. Establishing trustworthiness remains paramount in the industrial rubber door seal industry. Leading manufacturers offer comprehensive warranties, underlining their confidence in product longevity and performance. Certifications, such as ISO standards, further assure customers of the product's quality and reliability. These certifications are a testament to the rigorous testing and quality control processes that the seals undergo before reaching the market. For customers seeking to purchase industrial rubber door seals, making informed decisions necessitates attention to these pivotal factors. Ensuring the compatibility of the rubber material with the intended environmental conditions is crucial. Collaborating with reputable manufacturers who disclose detailed product specifications and performance data can safeguard against inferior products that may lead to costly repairs or replacements. In conclusion, industrial rubber door seals stand as essential components across various industries. Their role in enhancing energy efficiency, providing environmental protection, and sustaining operational stability cannot be overstated. Through continuous innovation, stringent quality control, and a commitment to addressing customer needs, the industry exemplifies the highest standards of expertise and trustworthiness, ensuring that these unobtrusive yet vital elements continue to support our modern industrial framework effectively.

Share

Previous:

Next:

Latest news

-

The Ultimate Guide to Square Files for Precision WorkNewsJun.26,2025

-

The Power of Flat FilesNewsJun.26,2025

-

Revolutionize Your Craft with High-Performance Rotary FilesNewsJun.26,2025

-

Precision and Durability with Diamond-Coated Needle FilesNewsJun.26,2025

-

Essential Tools for Precision Work: Round Metal Files and MoreNewsJun.26,2025

-

Essential Tools for Precision Sharpening: Triangular FilesNewsJun.26,2025