Product description:

Material requirements for aluminum guide rollers. Aluminum guide rollers must be made of high-strength and wear-resistant aluminum alloy materials to ensure that they can withstand significant pressure and friction during rolling processing without deformation or damage. At the same time, aluminum guide rollers also require good thermal conductivity to facilitate timely heat dissipation and avoid affecting processing quality due to high temperatures.

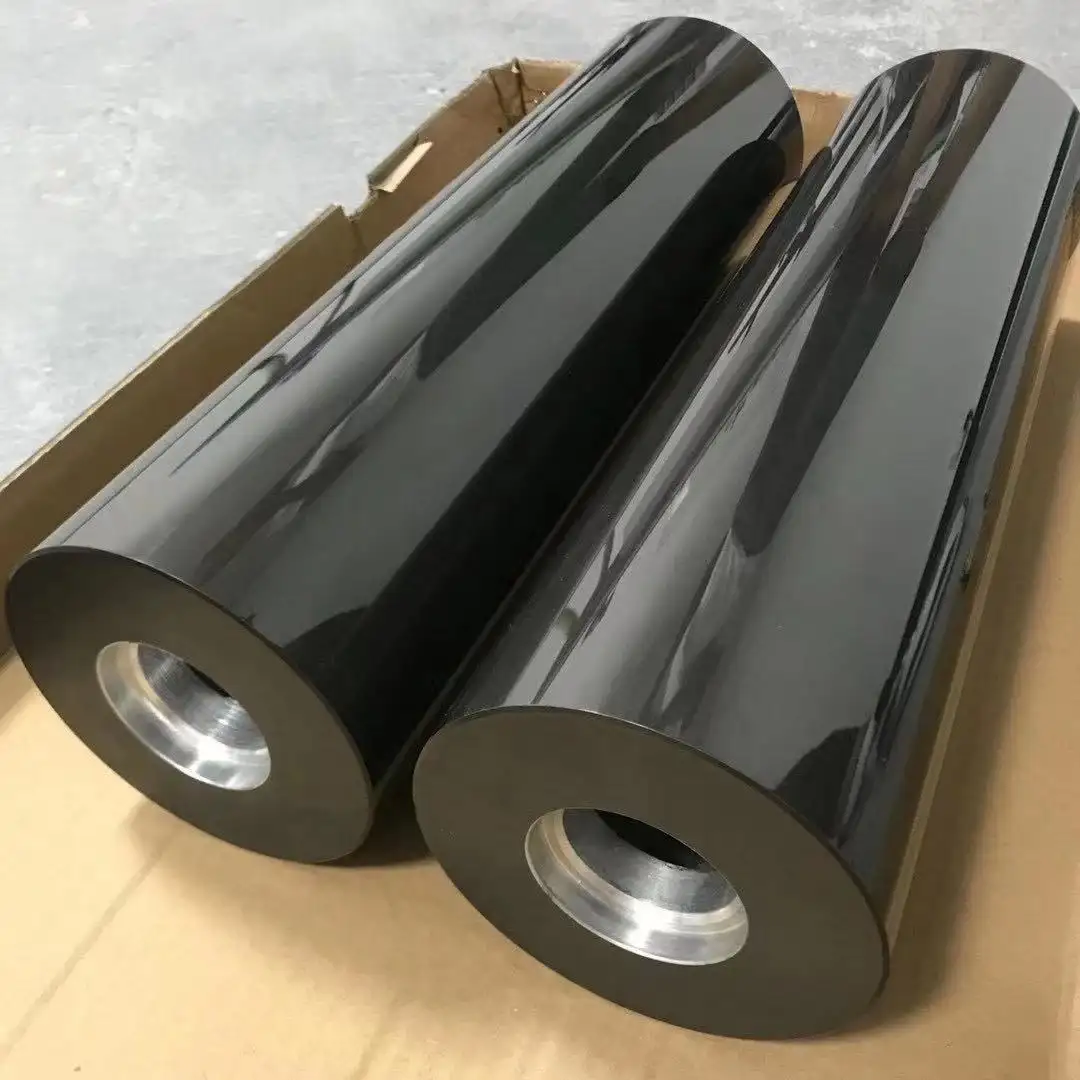

Aluminum guide rollers are also called aluminum alloy guide rollers. They are made of high-quality aluminum alloy materials (6063-T5) and are suitable for industries such as lithium battery production line, printing, packaging, plastics, and so on.

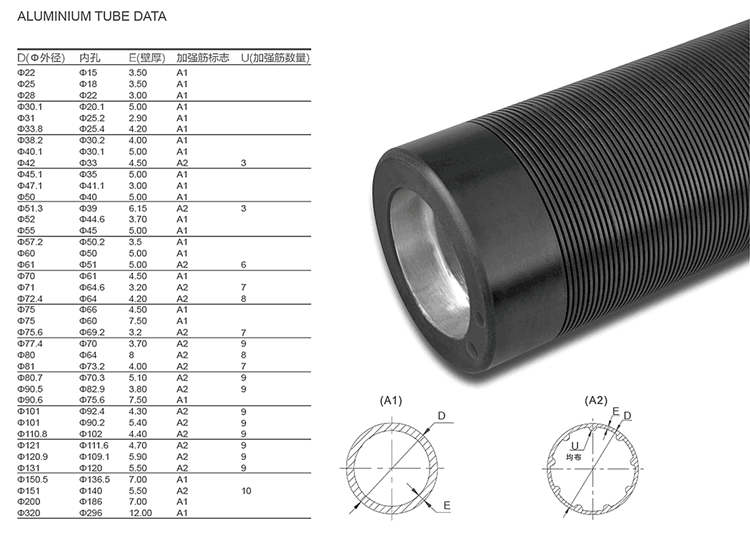

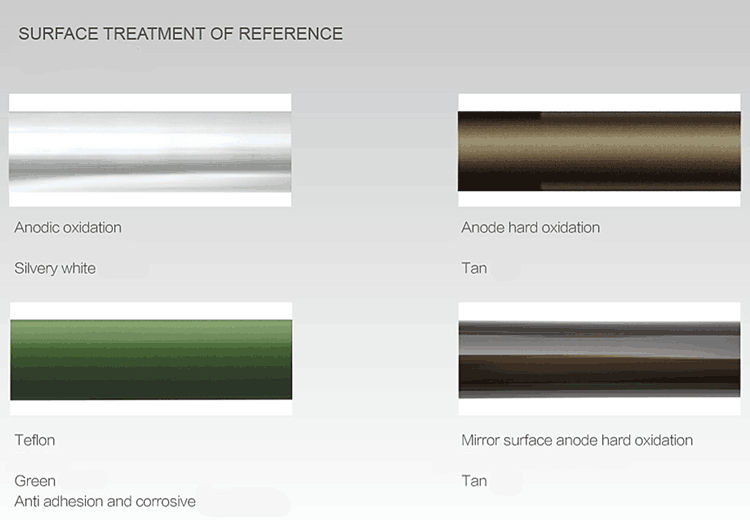

It is formed into a tube shape (from 30mm to 220mm in outer diameter) through a variety of specifications, with a rib structure inside, and high strength. And use precision equipment and special tools to finish the surface to make the surface smooth, the coaxiality reaches 0.02mm, the entire shaft is processed by computer balance correction within 2g, and the special technology of the shaft end and the imported bearings can be used under high-speed operation. Operate with ease. According to the different needs of the industry, the surface can also be specially treated: sand blasting, netting, Teflon and special hardening HV700 to make it have good scratch resistance and wear resistance.

Advantages:

- There is a rib structure in the aluminum guide roller, which makes it very strong.

- We use precision equipment and special tools to finish the surface to make the surface smooth and the concentricity reaches 0.02mm.

- Dynamic balance accuracy within 2g

In the production process, through the hot set matching process and the appearance of the CNC lathe, the aluminum guide roller can obtain high bonding strength and precision, good linearity and concentricity, and a high-speed dynamic balancing system can ensure static balance With high-speed dynamic balancing performance, it can ensure that aluminum guide rollers run on the machine at high speed without vibration.

- Low resistance, light weight, flexible rotation, no rust, wear resistance and corrosion resistance

5.We can customize according to the customer's requirements.

News