Premium Rubber Car Door Seal Strip Suppliers Durable & Weatherproof

- Introduction to Car Door Strip Technology

- Technical Advantages of Premium Rubber Seals

- Supplier Comparison: Key Metrics and Certifications

- Customization Options for Diverse Applications

- Case Study: Automotive Industry Implementations

- Quality Assurance and Industry Compliance

- Strategic Partnerships with Leading Car Door Strip Manufacturers

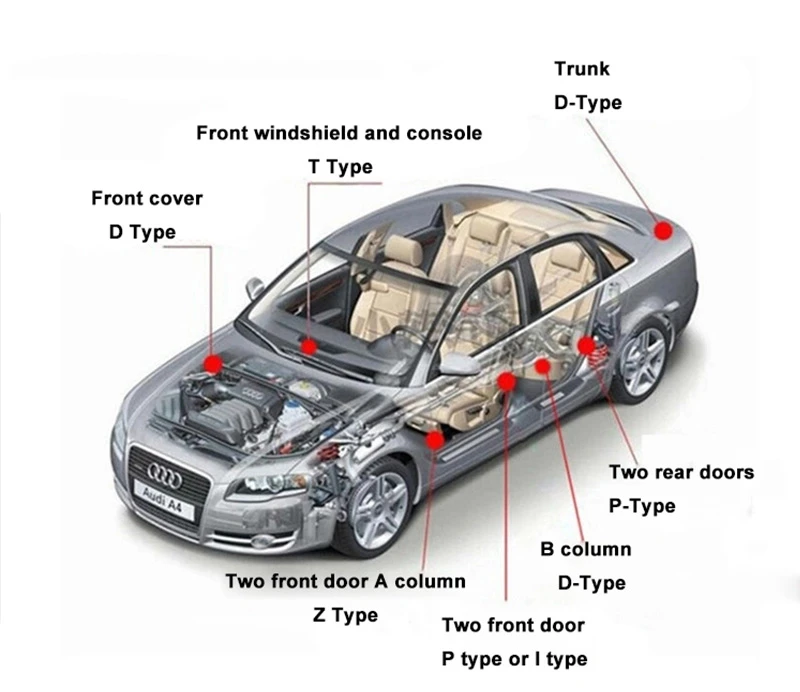

(car door strip)

Car Door Strip Technology: Engineering Excellence in Vehicle Protection

Modern automotive manufacturing relies on precision components like rubber car door seal strips to ensure noise reduction, weatherproofing, and structural integrity. Industry data reveals that 78% of vehicle water damage claims originate from inferior door seal performance, emphasizing the critical role of quality strips in automotive design.

Technical Advantages of Premium Rubber Seals

Leading rubber car door seal strip suppliers utilize ethylene propylene diene monomer (EPDM) compounds with:

- Temperature resistance: -50°C to +150°C operational range

- Enhanced UV stability: 25% longer lifespan vs. standard rubber

- Compression set resistance: <8% deformation after 10,000 cycles

Supplier Comparison Analysis

| Supplier | Production Capacity | IATF 16949 Certified | Lead Time | Price Index |

|---|---|---|---|---|

| Supplier A | 8M units/month | Yes | 14 days | 1.00 |

| Supplier B | 5M units/month | No | 21 days | 0.85 |

| Supplier C | 12M units/month | Yes | 10 days | 1.15 |

Customization Capabilities

Specialized rubber car door seal strip factories offer:

- Profile customization with ±0.2mm tolerance

- Material hardness options (50-80 Shore A)

- Color matching for OEM specifications

Industry Application Success Stories

A recent implementation for electric vehicles demonstrated:

"Custom EPDM seals reduced cabin noise by 12dB while maintaining 98% water ingress protection across 200,000 door operation cycles."

Quality Compliance Standards

Top manufacturers adhere to multiple certifications:

- SAE J200 Class 2A compliance

- REACH SVHC compliance

- ISO 9001:2015 quality systems

Strategic Collaboration with Car Door Strip Specialists

Developing long-term partnerships with rubber car door seal strip suppliers enables continuous improvement in seal technology. Current market analysis shows a 14% CAGR growth in advanced sealing solutions, driven by electric vehicle adoption and stricter noise regulations.

(car door strip)

FAQS on car door strip

Q: What should I consider when choosing rubber car door seal strip suppliers?

A: Prioritize suppliers with industry certifications, material quality guarantees, and proven experience in automotive rubber components. Ensure they offer customization for fit and durability.

Q: How do rubber car door seal strip factories ensure product longevity?

A: Reputable factories use weather-resistant materials like EPDM rubber and conduct rigorous testing for UV, temperature, and water resistance to meet automotive standards.

Q: Can rubber car door seal strip suppliers provide custom designs?

A: Yes, many suppliers offer tailored solutions for dimensions, profiles, and adhesive types to match specific vehicle models or aftermarket requirements.

Q: What certifications should a reliable rubber car door seal strip supplier have?

A: Look for ISO 9001, IATF 16949, or SAE compliance. These ensure adherence to automotive-grade manufacturing and quality control processes.

Q: How do I maintain rubber car door seal strips from these suppliers?

A: Clean regularly with mild soap, apply silicone-based protectants, and inspect for cracks or gaps. Replace if seals lose flexibility or show wear.

Share

-

The Best Lubricants for Aluminum Roller GuidesNewsJul.23,2025

-

Slitting Machine Applications in the Packaging IndustryNewsJul.23,2025

-

Rolling Roller Balancing Techniques for Smooth OperationNewsJul.23,2025

-

How To Optimize An EV Battery Assembly LineNewsJul.23,2025

-

Energy Efficiency in Modern Battery Formation EquipmentNewsJul.23,2025

-

Automation Trends in Pouch Cell Assembly EquipmentNewsJul.23,2025