Door Trim Rubber Seal | Weatherproof, Soundproof, Easy Fit

Door Trim Rubber Seal is a key solution in the manufacturing industry, specifically within automobile manufacturing industry and Manufacturing of automotive parts and accessories. This article explores how XINGTAI SHUODING TRADING CO.,LTD supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Door Trim Rubber Seal Overview

- Benefits & Use Cases of Door Trim Rubber Seal in Manufacturing of automotive parts and accessories

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Door Trim Rubber Seal from XINGTAI SHUODING TRADING CO.,LTD

Door Trim Rubber Seal Overview

A door trim rubber seal is a co-extruded profile fitted around the vehicle door aperture and window channels to close gaps, prevent water and dust ingress, and reduce NVH. In the Manufacturing of automotive parts and accessories, it is fundamental to door closing feel, cabin comfort, and warranty performance. Typical constructions combine a push-on U-channel (with metal carrier) and a compressible bulb or lip. XINGTAI SHUODING TRADING CO.,LTD engineers seals using EPDM sponge/solid, TPV/TPE, or hybrid compounds to meet diverse OEM specs for hardness, compression set, and environmental resistance.

Technical snapshots for buyers and engineers: - Material: EPDM (UV/ozone resistant) or TPV/TPE options; Shore A 50–75 for solid sections - Temperature range: -40°C to 120°C (material-dependent) - Geometry: bulb diameters typically 10–20 mm; co-extruded skin; optional flocking for glass run - Attachment: metal-reinforced U-channel, pre-applied acrylic foam adhesive (e.g., 3M class) or clip-in - Standards: produced under ISO 9001 and IATF 16949 quality systems; PPAP/APQP support available

As a reliable manufacturer and exporter, XINGTAI SHUODING TRADING CO.,LTD pairs in-house compounding with precise die design to deliver consistent sealing force and fit across model variants, ensuring a repeatable “solid close” impression that OEMs demand.

Benefits & Use Cases of Door Trim Rubber Seal in Manufacturing of automotive parts and accessories

In automotive programs, door trim rubber seals are applied on door apertures, glass run channels, beltline interfaces, tailgates, and even panoramic roof surrounds. For EVs and luxury segments, optimized bulb geometry and skin friction management reduce wind noise and squeak/chatter. In commercial vehicles, robust profiles offer stable sealing over high door cycle counts and rough usage. XINGTAI SHUODING TRADING CO.,LTD supports both new model launches and value engineering for facelifts, offering tailor-made cross-sections to balance pull-in force, slam effort, and water management.

Key advantages: - Co-extruded EPDM/TPV blends for durable, low compression set performance - Pre-applied adhesive options for faster line installs and consistent placement - Anti-stretch cords and corner radius control for dimensional stability - Low-odor, low-VOC compounds to meet cabin air quality targets - Customizable to industry-adjacent needs such as door window rubber seal strips, flat rubber seal strip profiles, or specifications related to double door rubber seal, double glazed door rubber seals, and even fire door rubber seal requirements in non-automotive contexts

With deep tooling expertise and rapid sampling, XINGTAI SHUODING TRADING CO.,LTD helps Tier-1s and OEMs compress development timelines while maintaining robust sealing performance and a premium tactile close.

Cost, Maintenance & User Experience

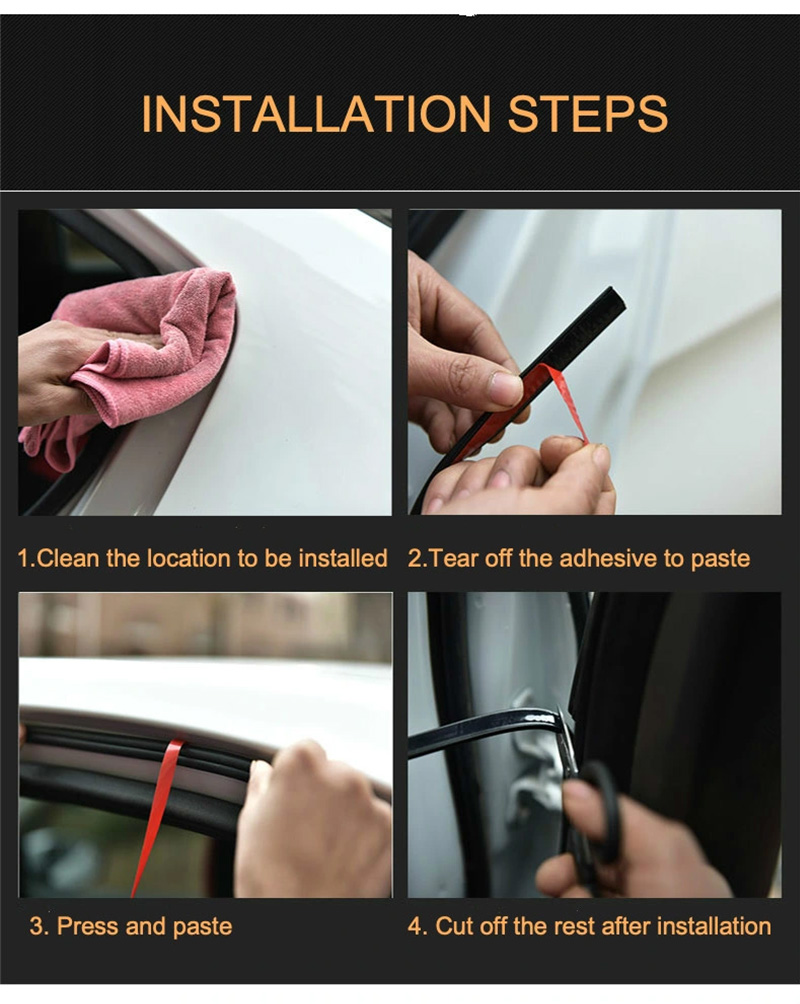

Total cost of ownership for a door trim rubber seal depends on profile design, material selection, installation method, and lifecycle durability. By using co-extruded EPDM or TPV with stable compression set, the seals maintain door flushness and closing effort over years of use, which can help reduce water leak claims, wind-noise complaints, and rework. Pre-taped, peel-and-stick solutions may cut assembly time and hardware costs (fewer clips/studs), improving takt time and reducing line variability—benefits that typically outweigh marginal material cost differences in B2B programs.

From field feedback, manufacturers report a more consistent “thunk,” better NVH at highway speeds, and fewer service interventions when seals are properly specified and installed. Maintenance is minimal: periodic cleaning with mild soap to remove dust/road film preserves elasticity and surface finish; avoid solvent wipes that can prematurely age elastomers. For adhesive-backed variants, advise 24-hour cure before exposure to pressure washing. XINGTAI SHUODING TRADING CO.,LTD provides application guides, handling instructions, and packaging that reduces coil set, further lowering scrap and supporting predictable ROI across vehicle lifecycles.

Sustainability & Market Trends in manufacturing

Global trends impacting seals include stricter pass-by noise targets, enhanced water management for BEVs (battery protection), and compliance with REACH, RoHS, and ELV. OEMs are also emphasizing lower VOC interiors and recyclability. TPV/TPE alternatives, refined curing systems, and optimized profiles help reduce mass and energy usage in both production and vehicle operation. Seals designed for durability extend service life, indirectly minimizing waste and resource consumption over the vehicle’s total mileage.

XINGTAI SHUODING TRADING CO.,LTD is aligning with these priorities by offering low-odor formulations, halogen-free materials, and options that support material recovery programs where feasible. The company’s process controls and quality systems help minimize scrap, while collaborative engineering avoids over-designing sections—achieving target sealing force with less material. For customers seeking multi-industry harmonization, insights from architectural sealing (e.g., double glazed door rubber seals, fire door rubber seal) are applied prudently to automotive-grade requirements, creating efficient, future-ready solutions.

Conclusion on Door Trim Rubber Seal from XINGTAI SHUODING TRADING CO.,LTD

A well-engineered Door Trim Rubber Seal is integral to water tightness, NVH, door closing feel, and long-term reliability in the automobile manufacturing industry. XINGTAI SHUODING TRADING CO.,LTD combines robust materials, precise tooling, and automotive quality systems to deliver consistent, cost-effective performance for OEM and Tier-1 programs. Whether you need classic profiles, door window rubber seal strips, or flat rubber seal strip adaptations, the team can customize to your platform targets. Contact us: email: sdtrading0927@126.com — Visit our website: https://www.xtshuoding.com

Share

-

Lithium Battery Welding Machine | High-Precision, Fast, SafeNewsNov.17,2025

-

Aluminium Guide Roller | Anodized, Lightweight, Low-NoiseNewsNov.17,2025

-

Tofu Cat Litter Bulk – Eco, Low-Dust, Fast Clumping SupplyNewsNov.17,2025

-

Equipment for Lithium Cell Assembly | Automated & PreciseNewsNov.10,2025

-

Square File Tool – Precision Cut, Hardened Steel, VersatileNewsNov.10,2025

-

Lithium Ion Battery Assembly Machine | Automated, High-SpeedNewsNov.10,2025