Lithium Cell Machinery: Automated, High-Precision, Turnkey

Lithium Cell Machinery is a key solution in the manufacturing industry, specifically within Special Equipment Manufacturing Industry and Manufacturing of specialized electronic and electrical machinery equipment. This article explores how XINGTAI SHUODING TRADING CO.,LTD supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Lithium Cell Machinery Overview

- Benefits & Use Cases of Lithium Cell Machinery in Manufacturing of specialized electronic and electrical machinery equipment

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Lithium Cell Machinery from XINGTAI SHUODING TRADING CO.,LTD

Lithium Cell Machinery Overview

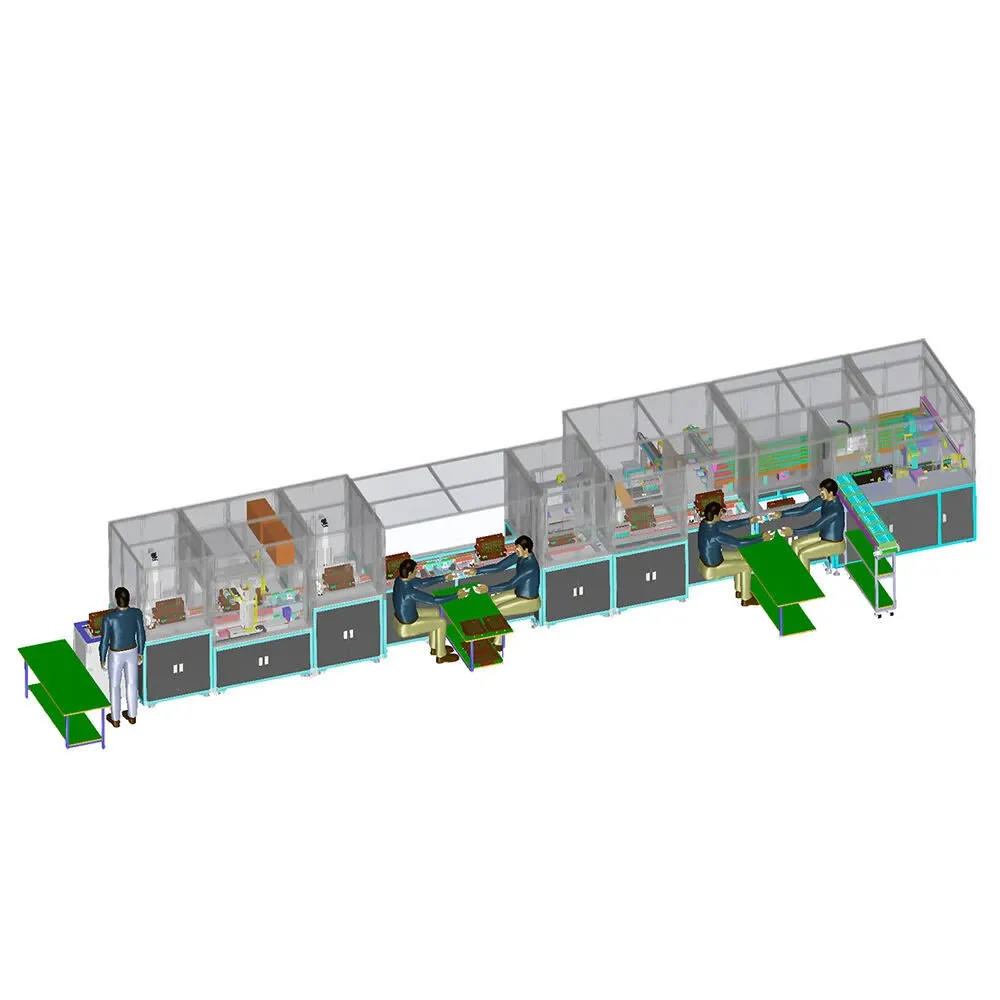

Lithium Cell Machinery refers to integrated automation systems that handle cell sorting, tab welding, stacking/winding, electrolyte filling, sealing, formation/aging, and end-of-line testing for lithium-ion cells and packs. In the Special Equipment Manufacturing Industry—especially within Manufacturing of specialized electronic and electrical machinery equipment—these systems convert manual, variable processes into stable, high-throughput operations. Modern lines combine precision motion control, machine vision, and MES/SCADA connectivity to deliver consistent quality and full traceability from incoming cells to finished battery packs.

Technical highlights typically include micron-level positioning for ultrasonic or laser welding, OCV/IR testing, automated cell grading, and closed-loop SPC. Modular stations support common formats such as 18650, 21700, prismatic, and pouch cells, while quick-change tooling reduces downtime. A representative setup from XINGTAI SHUODING TRADING CO.,LTD integrates high-speed conveyors, smart jigs/fixtures, and safety interlocks for reliable pack assembly. With robust architecture and industrial components, these lines are engineered to maintain high OEE and repeatability across multi-shift production—key for battery assembly line manufacturers serving EVs, ESS, and power tools markets. XINGTAI SHUODING TRADING CO.,LTD provides proven lithium ion battery production equipment that aligns with B2B expectations for scalability and compliance.

Benefits & Use Cases of Lithium Cell Machinery in Manufacturing of specialized electronic and electrical machinery equipment

Across EV battery pack lines, stationary energy storage, consumer electronics, e-bikes/scooters, telecom backup, and industrial AGVs/AMRs, Lithium Cell Machinery standardizes production and guarantees repeatable welds, precise cell placement, and reliable electrical testing. As a lithium ion battery assembly line scales, automation reduces labor intensity, mitigates ergonomic risks, and enhances first-pass yield through automated inspection and recipe-controlled processes. Integration with ERP/MES systems enables component traceability, lot genealogy, and real-time dashboards for quality and throughput.

Competitive advantages include modular cell-to-pack configurations, compatibility with pouch/prismatic/cylindrical formats, high-precision ultrasonic/laser welding, and configurable fixtures for different pack geometries. Vision-guided placement, barcode/RFID tracking, and parameter interlocks improve quality assurance. XINGTAI SHUODING TRADING CO.,LTD specializes in turnkey lithium ion battery assembly machines and lithium ion battery production equipment, delivering balanced lines from incoming cell preparation to EOL validation. For B2B decision makers evaluating battery assembly line manufacturers, SHUODING’s solutions provide a pragmatic combination of throughput, flexibility, and lifecycle support, helping operations meet aggressive launch schedules without sacrificing reliability.

Cost, Maintenance & User Experience

Total cost of ownership for Lithium Cell Machinery spans CAPEX, utilities, consumables, planned maintenance, and operator training. The business case hinges on throughput, yield, uptime, and changeover efficiency. Durable frames, standardized spare parts, and energy-efficient drives reduce lifecycle costs. Predictive maintenance—enabled by vibration/temperature sensors and cycle counters—helps organizations plan interventions, protect critical components, and maintain stable takt times. For many operations, ROI is driven by scrap reduction, fewer reworks, and optimized labor allocation as lines scale.

Customers in the Special Equipment Manufacturing Industry report smoother SOP adoption when HMIs are intuitive, alarms are contextual, and documentation is comprehensive. XINGTAI SHUODING TRADING CO.,LTD focuses on user-centric design, remote diagnostics, and on-site commissioning to minimize ramp-up time. Their maintenance approach includes training packages, recommended spare kits, and clear PM intervals to sustain performance. B2B users value that the lithium ion battery assembly line can adapt as product portfolios evolve—supporting new cell formats, additional safety checks, or upgraded test modules without wholesale redesign.

Sustainability & Market Trends in manufacturing

Global electrification, grid-scale storage, and tightening regulations are accelerating investments in advanced lithium ion battery assembly lines. Trends include deeper digitalization (IIoT data streams, AI-driven inspection), closed-loop process control for uniform quality, and rigorous traceability from raw materials to finished packs. Regulatory frameworks increasingly emphasize product carbon footprint transparency, responsible sourcing, and end-of-life considerations. Production lines that capture detailed process data and enable efficient rework or recycling pathways better support these requirements and customer audits.

XINGTAI SHUODING TRADING CO.,LTD designs Lithium Cell Machinery with sustainability in mind: energy-conscious motion systems, waste-minimizing fixturing, and process settings that strive to reduce scrap. Cleanroom-ready modules, fume extraction interfaces, and solvent-handling safeguards support safe, compliant operations. By enabling high first-pass yield and comprehensive traceability, SHUODING’s solutions help manufacturers align with market expectations for greener, more responsible lithium ion battery production equipment—without compromising productivity or flexibility.

Conclusion on Lithium Cell Machinery from XINGTAI SHUODING TRADING CO.,LTD

For manufacturers in the Special Equipment Manufacturing Industry, Lithium Cell Machinery delivers scalable throughput, robust quality control, and end-to-end traceability. By combining modular hardware with smart software and ergonomic design, XINGTAI SHUODING TRADING CO.,LTD equips B2B operations to meet demand across EV, ESS, and industrial applications. Their expertise as battery assembly line manufacturers ensures a reliable partner for launch, ramp, and continuous improvement. Contact us: email: sdtrading0927@126.com — Visit our website: https://www.xtshuoding.com

Share

-

Lithium Battery Welding Machine | High-Precision, Fast, SafeNewsNov.17,2025

-

Aluminium Guide Roller | Anodized, Lightweight, Low-NoiseNewsNov.17,2025

-

Tofu Cat Litter Bulk – Eco, Low-Dust, Fast Clumping SupplyNewsNov.17,2025

-

Equipment for Lithium Cell Assembly | Automated & PreciseNewsNov.10,2025

-

Square File Tool – Precision Cut, Hardened Steel, VersatileNewsNov.10,2025

-

Lithium Ion Battery Assembly Machine | Automated, High-SpeedNewsNov.10,2025