High-Precision Pouch Cell Assembly Equipment & Solutions

Navigating the Future of Energy: Advanced Pouch Cell Manufacturing

The rapid evolution of electric vehicles (EVs), grid-scale energy storage systems (ESS), and advanced consumer electronics has significantly amplified the demand for high-performance, compact, and energy-dense battery solutions. Among various battery architectures, pouch cells have emerged as a frontrunner due to their excellent energy density, flexible form factor, and superior thermal management capabilities. Consequently, the efficiency and precision of pouch cell assembly equipment are paramount for manufacturers aiming to meet stringent market demands and achieve cost-effective production at scale. This comprehensive guide delves into the critical aspects of pouch cell manufacturing, covering industry trends, technical intricacies, application benefits, and our specialized turnkey solutions.

Pouch Cell Manufacturing Industry Trends

The global battery market is experiencing unprecedented growth, driven by ambitious decarbonization goals and technological advancements. Pouch cells, in particular, are gaining traction due to their design flexibility, which allows for maximum space utilization in complex applications. Key trends include:

- Increased Automation and AI Integration: To achieve higher throughput, superior quality control, and reduced labor costs, modern pouch cell manufacturing lines are heavily investing in robotics, automated material handling, and AI-driven process optimization. This minimizes human error and enhances production consistency.

- Emphasis on Advanced Chemistries: While LFP (Lithium Iron Phosphate) remains popular for its safety and cost-effectiveness, NMC (Nickel Manganese Cobalt) continues to evolve for higher energy density in EVs, and LTO (Lithium Titanate Oxide) is preferred for its ultra-fast charging and extended cycle life in specific industrial applications. Flexible pouch cells equipment production must accommodate these diverse material needs.

- Scalability and Modularity: Manufacturers require solutions that can scale from pilot lines to GWh-scale production without complete overhauls. Modular designs facilitate easier upgrades, maintenance, and capacity expansion, critical for meeting fluctuating market demands.

- Sustainability and Circular Economy: There's a growing focus on sustainable manufacturing practices, including energy-efficient processes, reduced waste generation, and designs that facilitate future battery recycling.

- Enhanced Quality Control and Safety: With increasing energy density, ensuring the safety and long-term reliability of pouch cells is paramount. Advanced inline inspection systems, precise defect detection, and robust safety protocols are becoming standard for all pouch cell battery assembly lines.

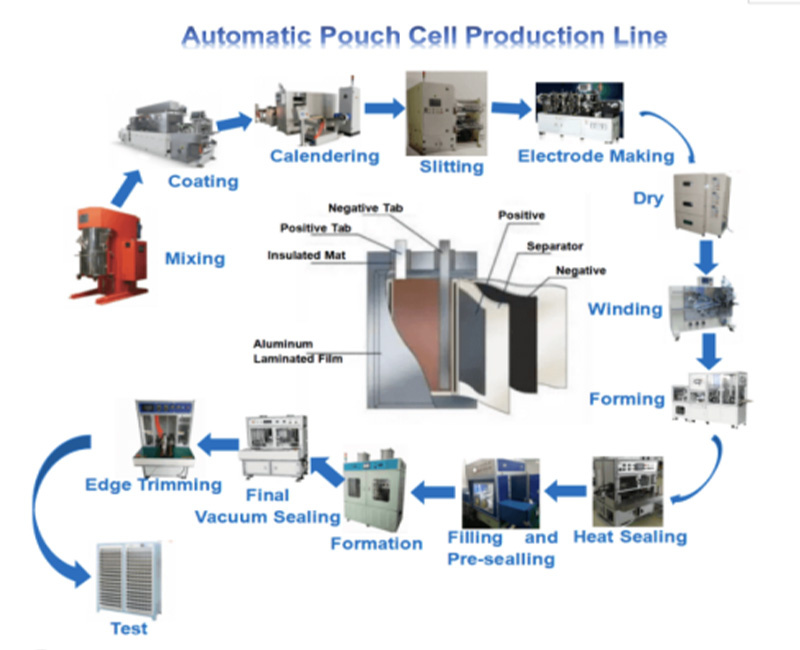

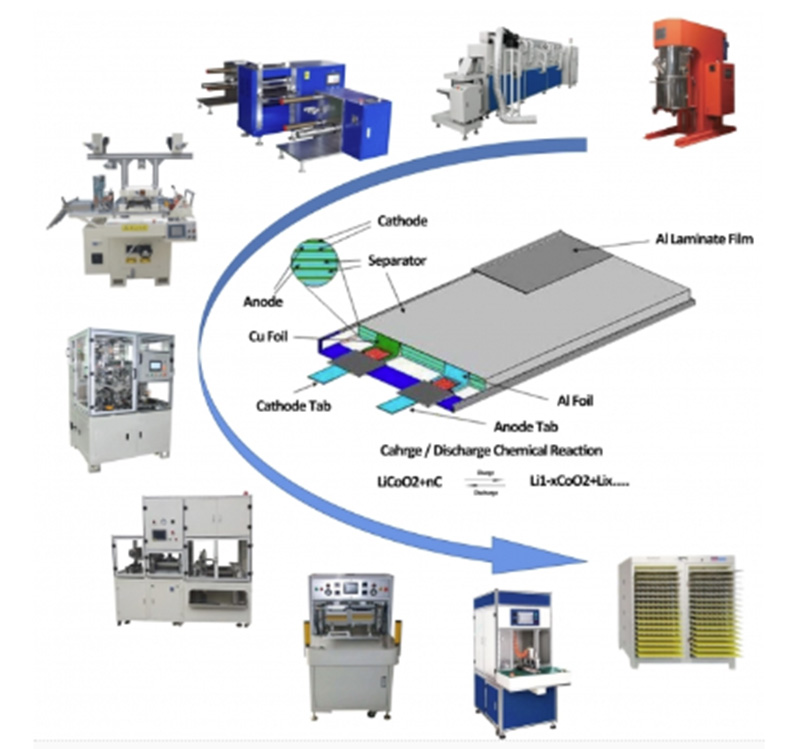

Detailed Pouch Cell Manufacturing Process Flow

The production of pouch cells involves a sophisticated sequence of highly precise steps, each critical for the final battery's performance and safety. Our 100MWH/1GWh LFP/NMC/LTO Turnkey Pouch Cell Manufacturing Line integrates advanced pouch cells equipment production to ensure optimal efficiency and quality. The process typically includes:

1. Electrode Preparation

- Slurry Mixing: Active materials (LFP, NMC, LTO), conductive additives, and binders are precisely mixed with solvents to create a homogeneous slurry. This step demands high-shear mixers and vacuum degassers.

- Coating: The slurry is precisely coated onto thin metal foils (aluminum for cathode, copper for anode) using precision coating machines (e.g., doctor blade or slot die coater). Uniformity is critical.

- Drying: Coated foils pass through multi-zone ovens for solvent evaporation, leaving behind a porous electrode material.

- Calendering: Dried electrodes are compressed by calendering machines to achieve desired thickness and porosity, enhancing energy density and adhesion.

- Slitting: Large electrode rolls are slit into narrower strips of precise width, ready for cell assembly.

2. Cell Assembly (Dry Room Environment)

- Notching: Precision laser or mechanical notching machines cut the current collector tabs into the electrode sheets. This process requires high accuracy, often using CNC machining for tool fabrication and precise material handling.

- Stacking/Winding: This is a core part of pouch cell battery assembly. In stacking, individual cathode, separator, and anode sheets are precisely stacked alternately. For winding, continuous sheets are wound together. Advanced stacking machines ensure alignment accuracy within ±50µm.

- Tab Welding: Ultrasonic welding is typically used to weld multiple current collector tabs together and then to the external lead tabs, ensuring low resistance connections.

- Packaging/Sealing: The stacked/wound cell is inserted into an aluminum-plastic laminated film (pouch film). The edges are heat-sealed, typically leaving one side open for electrolyte filling. Precision heat sealing machines prevent leaks and ensure mechanical integrity.

3. Electrolyte Filling & Formation

- Vacuum Electrolyte Filling: The electrolyte is injected into the pouch cell under vacuum conditions to ensure complete impregnation of the electrodes and separator, eliminating air bubbles.

- Pre-Sealing & Degassing: After a brief soaking period, the pouch cell is partially sealed, leaving a small opening. During initial charging (formation), gases are produced, which are then vented out (degassing) before final sealing.

- Formation & Aging: Cells undergo a controlled charge-discharge cycle (formation) to form the Solid Electrolyte Interphase (SEI) layer, critical for long-term performance. This is followed by an aging period to stabilize the cell chemistry.

4. Testing & Finishing

- Open Circuit Voltage (OCV) & Internal Resistance (IR) Testing: Cells are tested for their electrical characteristics to ensure they meet specifications.

- Sorting: Based on OCV, IR, and capacity, cells are sorted into different grades.

- Final Inspection: Visual inspection and X-ray imaging can be employed for final quality assurance.

Our equipment adheres to stringent testing standards such as ISO 9001 for quality management and relevant ANSI/UL standards for safety where applicable. Component materials for our equipment are selected for superior corrosion resistance and durability, contributing to an expected service life of 10-15 years with proper maintenance. These manufacturing lines are pivotal for target industries including automotive (EV batteries), renewable energy (grid-scale ESS), and consumer electronics (portable devices).

Technical Specifications and Advantages of Our Turnkey Line

Our 100MWH/1GWh LFP/NMC/LTO Turnkey Pouch Cell Manufacturing Line is engineered for high-volume, high-precision production of advanced pouch cells. This integrated solution embodies state-of-the-art pouch lithium ion cells equipment production, designed for optimal performance across various chemistries.

Product Specification Table: 100MWH/1GWh Turnkey Pouch Cell Manufacturing Line

| Parameter | Specification | Description |

|---|---|---|

| Production Capacity | 100 MWh to 1 GWh/year | Scalable production for small to large scale requirements. |

| Supported Cell Chemistries | LFP, NMC, LTO | Versatile for various battery types and applications. |

| Cell Size Range | Customizable (e.g., 50x80mm to 200x300mm) | Accommodates a broad spectrum of pouch cell dimensions. |

| Stacking Precision | ±50 µm | High accuracy for consistent cell quality and performance. |

| Automation Level | Fully Automated to Semi-Automated options | Reduces labor costs and human error, increases throughput. |

| Yield Rate | >95% (with optimal operation) | Minimizes material waste and maximizes output. |

| Energy Consumption | Optimized for efficiency | Designed to reduce operational costs, enhancing sustainability. |

| Dry Room Requirements | Dew Point < -60°C | Ensures optimal conditions for hygroscopic electrolyte and materials. |

| Compliance | ISO 9001, CE Certified Equipment | Adherence to international quality and safety standards. |

Technical Advantages:

- High Precision and Accuracy: Utilizing advanced sensor technology, machine vision, and robotic control, our pouch cell assembly equipment ensures sub-millimeter precision in electrode stacking, tab welding, and sealing, crucial for cell longevity and safety.

- Exceptional Throughput and Yield: Optimized cycle times and robust process control contribute to industry-leading throughput and consistently high yield rates, directly impacting profitability.

- Modular and Flexible Design: The modular architecture allows for easy customization, capacity upgrades, and adaptation to new cell formats or chemistries without extensive retooling, future-proofing your investment.

- Integrated Quality Control: Every critical step includes inline inspection and feedback loops, ensuring defects are detected and addressed immediately, minimizing scrap and enhancing product reliability.

- Energy Efficiency: Components are selected for energy optimization, such as high-efficiency motors and precise temperature control systems for ovens and dry rooms, leading to significant energy savings in operational expenditures. This is particularly beneficial in industries like petrochemical and metallurgy where energy costs are substantial.

- Enhanced Safety Features: Comprehensive safety interlocks, emergency stop systems, and robust design prevent operational hazards, protecting personnel and infrastructure.

Application Scenarios and Exemplary Advantages

The versatility of pouch cells makes them ideal for a multitude of applications. Our pouch cell manufacturing process equipment is designed to serve diverse industries requiring high-performance battery solutions.

Electric Vehicles (EVs):

Pouch cells are favored in EVs for their excellent gravimetric and volumetric energy density, enabling longer driving ranges and efficient packaging within tight vehicle architectures. Our equipment ensures precise, high-volume production of automotive-grade cells with consistent quality, critical for battery pack reliability and safety. The ability to produce various cell sizes and chemistries (NMC for performance, LFP for cost-effectiveness) allows EV manufacturers to diversify their offerings.

- Advantage: Energy Saving. Our efficient drying ovens and optimized formation cycles reduce energy consumption per cell, driving down overall production costs for high-volume EV battery manufacturers.

Grid-Scale Energy Storage Systems (ESS):

For stationary energy storage, pouch cells offer robust performance, high cycle life, and scalability. They are vital for integrating renewable energy sources and stabilizing grids. The modular design of our pouch cell assembly equipment facilitates rapid deployment and expansion of battery production to meet the burgeoning demand for ESS, particularly with LFP chemistry for its safety and longevity.

- Advantage: Corrosion Resistance. Equipment components exposed to harsh environments or chemicals, such as electrolyte filling nozzles and sealing components, are built with corrosion-resistant materials, ensuring durability and consistent performance in demanding production environments, reflecting advantages seen in petrochemical and water supply & drainage sectors for other equipment.

Consumer Electronics:

Smartphones, laptops, and wearables benefit immensely from the flexible form factor and high energy density of pouch cells, allowing for sleek designs and extended battery life. Our equipment's precision ensures consistent production of miniature, high-performance cells, meeting the strict quality and size requirements of the consumer electronics market.

- Advantage: Precision & Miniaturization. The high accuracy of our stacking and notching equipment allows for the creation of ultra-thin and small pouch cells, critical for compact electronic devices.

Vendor Comparison: Why Choose Our Pouch Cell Assembly Equipment?

When investing in a turnkey pouch cell manufacturing line, distinguishing between vendors is critical. Our offerings stand apart by focusing on integrated solutions, unparalleled support, and proven performance.

Pouch Cell Assembly Equipment Vendor Comparison Factors

| Feature/Factor | Our Solution | Typical Competitor |

|---|---|---|

| Integration Level | Full Turnkey (100MWH-1GWh), single-vendor accountability, seamless integration. | Often component-based, requiring multiple vendors and integration efforts by client. |

| Chemistry Flexibility | LFP, NMC, LTO compatible without major retooling. | May be specialized for one chemistry or require significant modifications. |

| Customization & Scalability | Highly customizable, modular design for future upgrades and capacity expansion. | Limited customization, costly to scale or adapt to new requirements. |

| After-Sales Support | Global, rapid-response technical support, comprehensive training, local service partners. | Region-specific support, potentially slower response times, limited spare parts availability. |

| Technology Innovation | Continuous R&D, integration of AI/ML for predictive maintenance and process optimization. | Standard technology, slower adoption of advanced features. |

| Total Cost of Ownership (TCO) | Lower TCO due to high efficiency, reliability, minimal downtime, and longer service life. | Potentially higher TCO due to frequent maintenance, lower yield, and energy inefficiencies. |

Our expertise in developing robust pouch cell manufacturing solutions, backed by years of service and numerous successful deployments, positions us as a trusted partner. We hold certifications such as ISO 9001, demonstrating our commitment to quality across design, manufacturing, and support.

Customized Solutions

Recognizing that no two manufacturing operations are identical, we offer highly customized pouch cell assembly equipment solutions. Our engineering team collaborates closely with clients to design a manufacturing line that precisely fits their unique requirements:

- Capacity Scaling: From pilot lines for R&D to full GWh-scale mass production, we can tailor the line's output capacity.

- Chemistry Adaptation: Specific process adjustments and material handling for LFP, NMC, LTO, or even emerging battery chemistries.

- Space Optimization: Layout designs optimized for existing factory footprints, including multi-story or compact configurations.

- Automation Levels: Customizable automation levels, from semi-automated processes for specific stages to fully robotic end-to-end lines.

- Integration with Existing Systems: Seamless integration with current factory MES (Manufacturing Execution Systems) and ERP (Enterprise Resource Planning) platforms for centralized control and data management.

Our consultative approach ensures that every aspect of the project, from initial concept to commissioning, is aligned with your strategic objectives and operational excellence goals.

Application Case Studies

Case Study 1: High-Volume EV Battery Manufacturer

A major EV battery producer sought to establish a new GWh-scale facility to meet rising demand for their NMC pouch cells. They required a fully automated, high-precision manufacturing line. We provided a complete turnkey solution, from electrode preparation to final cell testing, integrating advanced robotic stacking and a bespoke electrolyte filling system.

- Result: The client achieved an impressive 96% yield rate and a 25% reduction in production time compared to their previous semi-automated lines, significantly increasing their capacity and reducing cost per cell. Our solution allowed them to ramp up production to 800 MWh/year within 18 months.

Case Study 2: Renewable Energy Storage Provider

A European energy storage company needed a robust and scalable pouch lithium ion cells equipment production line for LFP cells used in grid-scale ESS. Key requirements included high safety standards, long cycle life capability, and energy-efficient operations. We supplied a modular line with enhanced thermal management during formation and dedicated safety monitoring systems.

- Result: The client successfully deployed a 500 MWh/year facility, producing cells that consistently exceeded their specified cycle life targets by 15%. The energy-efficient design of our equipment also contributed to a 10% reduction in their overall operational electricity costs.

Frequently Asked Questions (FAQ)

Q1: What types of pouch cells can your equipment produce?

A1: Our turnkey pouch cell assembly equipment is designed to produce various types of pouch cells, including those based on LFP (Lithium Iron Phosphate), NMC (Nickel Manganese Cobalt), and LTO (Lithium Titanate Oxide) chemistries, with customizable cell dimensions.

Q2: What is the typical lead time for a 100MWh/1GWh manufacturing line?

A2: The lead time for a complete 100MWh/1GWh turnkey line typically ranges from 12 to 18 months, depending on the level of customization and specific equipment configurations. This includes design, manufacturing, factory acceptance testing (FAT), shipping, installation, and site acceptance testing (SAT).

Q3: What warranty and after-sales support do you offer?

A3: We provide a standard 12-month warranty on all our pouch cell manufacturing equipment, extendable upon request. Our comprehensive after-sales support includes 24/7 technical assistance, remote diagnostics, on-site service by expert engineers, spare parts supply, and continuous training programs for your operational staff.

Q4: How do you ensure the quality and safety of the produced cells?

A4: Our lines incorporate multiple inline quality control checkpoints, including machine vision inspection for electrode defects, precise stacking alignment verification, leak detection after sealing, and comprehensive OCV/IR testing. All equipment is designed to comply with international safety standards, minimizing risks throughout the pouch cell manufacturing process.

Lead Time & Fulfillment Details

Our project management methodology is designed for transparency and efficiency. Upon project initiation, a detailed timeline is provided, covering all phases from engineering design and component procurement (which involves processes like casting, forging, and precise CNC machining for critical parts), through manufacturing, assembly, and rigorous factory acceptance testing (FAT). The typical fulfillment timeframe for a turnkey 100MWh to 1GWh pouch cell assembly equipment line ranges from 12 to 18 months. This includes:

- Phase 1: Design & Engineering (2-4 months) - Customization, detailed layout, and process flow finalization.

- Phase 2: Manufacturing & Assembly (6-10 months) - Fabrication of equipment, sub-assembly, and system integration.

- Phase 3: Factory Acceptance Testing (FAT) (1 month) - Comprehensive testing at our facility before shipment.

- Phase 4: Shipping & Installation (2-3 months) - Logistics, on-site installation, and utility connections.

- Phase 5: Site Acceptance Testing (SAT) & Training (1 month) - Commissioning, performance validation, and operator training.

Warranty Commitments & Customer Support

Our commitment to our clients extends far beyond delivery. We offer a robust support framework to ensure the long-term, reliable operation of your pouch cell manufacturing line.

- Warranty: All new pouch cells equipment production comes with a standard 12-month warranty covering parts and labor against manufacturing defects. Extended warranty options are available.

- Global Technical Support: Our team of highly skilled engineers provides 24/7 multi-channel support, including phone, email, and remote diagnostics to address any operational issues promptly.

- On-Site Service: For complex issues or scheduled maintenance, our field service engineers are available for on-site visits to ensure minimal downtime.

- Spare Parts Availability: We maintain a comprehensive inventory of genuine spare parts, ensuring quick dispatch and reducing potential delays in your production schedule.

- Training Programs: We provide detailed training for your operators and maintenance personnel, empowering your team with the knowledge to efficiently run and maintain the production line.

- Performance Monitoring: Optional integration with cloud-based monitoring systems allows for real-time performance tracking, predictive maintenance, and optimized operational efficiency.

Conclusion

The future of energy is undeniably linked to advanced battery technologies, with pouch cells playing a pivotal role across electric mobility and stationary storage. Investing in cutting-edge pouch cell assembly equipment is not just an expenditure but a strategic imperative for manufacturers seeking to thrive in this dynamic landscape. Our 100MWH/1GWh LFP/NMC/LTO Turnkey Pouch Cell Manufacturing Line offers a robust, scalable, and highly efficient solution designed to meet the rigorous demands of modern battery production. By leveraging our expertise, comprehensive support, and customized engineering, partners can achieve unparalleled quality, yield, and cost-effectiveness, paving the way for sustainable and profitable growth in the global battery market.

References

- Electrochemical Society. "Journal of The Electrochemical Society." Peer-reviewed academic journal covering battery technology.

- ScienceDirect. "Energy Storage Materials." A leading journal for materials science related to energy storage.

- National Renewable Energy Laboratory (NREL). Research papers and reports on battery manufacturing and energy storage.

- IEEE Xplore Digital Library. Technical papers and conference proceedings on power electronics and battery systems.

- MDPI Batteries. Open access journal on all aspects of battery science and technology.

Share

-

Lithium Battery Welding Machine | High-Precision, Fast, SafeNewsNov.17,2025

-

Aluminium Guide Roller | Anodized, Lightweight, Low-NoiseNewsNov.17,2025

-

Tofu Cat Litter Bulk – Eco, Low-Dust, Fast Clumping SupplyNewsNov.17,2025

-

Equipment for Lithium Cell Assembly | Automated & PreciseNewsNov.10,2025

-

Square File Tool – Precision Cut, Hardened Steel, VersatileNewsNov.10,2025

-

Lithium Ion Battery Assembly Machine | Automated, High-SpeedNewsNov.10,2025