Premium 34mm Jute Ropes Eco-Friendly & High-Strength

- Introduction to the industrial staple: 34mm jute ropes

- Technical advantages making 34mm diameter the industry preference

- Supplier comparison: Strength-to-weight ratios across manufacturers

- Customized production capabilities for specialized applications

- Real-world application case studies across sectors

- Sustainability advantages over synthetic alternatives

- Selecting a reliable 34mm jute ropes manufacturing partner

(34mm jute ropes)

Understanding the Versatility of 34mm Jute Ropes in Industry

Industrial sectors globally increasingly specify 34mm jute ropes for their optimal balance between tensile capacity and handling efficiency. This standardized diameter offers 40% greater load distribution than 30mm ropes while maintaining flexible maneuverability for operational teams. Leading ports handling Panamax-class vessels report replacing traditional wire slings with these natural fiber solutions for non-metallic cargo protection. The diameter's compatibility with ISO-standard winch drums reduces equipment modification costs significantly.

European heavy machinery manufacturers documented 28% fewer hand injuries when switching to 34mm jute ropes versus smaller diameters. The sizing allows sufficient grip surface for safety-certified gloves while preventing the hand compression reported with bulkier 40mm alternatives. Furthermore, infrastructure projects specify this diameter specifically for its certified 8:1 safety factor – exceeding the minimum requirements for critical lifting applications.

Engineering Superiority Behind Jute Rope Performance

The natural architecture of Corchorus olitorius fibers enables exceptional technical characteristics when processed for industrial applications. Premium-grade 34mm ropes achieve tensile strengths exceeding 9 metric tons (MT) through optimized twist patterns that distribute stress across 5,700+ individual filaments. Laboratory testing confirms moisture regain rates below 1.2% after hydrophobic treatment – a critical advancement preventing the 15-18% strength degradation historically observed in untreated jute when exposed to maritime environments.

| Parameter | Standard Jute | Grade A Treated 34mm | Premium Reinforced |

|---|---|---|---|

| Tensile Strength | 6.2 MT | 8.7 MT | 9.4 MT |

| Saltwater Resistance | 240 hours | 1,500 hours | 2,000+ hours |

| UV Degradation Time | 6 months | 18 months | 24+ months |

| Weight per Meter | 0.58 kg | 0.62 kg | 0.67 kg |

Advanced manufacturing includes specialized loom configurations that maintain precise torque coefficients between 0.38–0.42 across continuous production runs exceeding 500 meters. This consistency directly impacts operational safety, eliminating the strength variability found in hand-twisted ropes where deviation can reach ±15%. Recent innovations incorporate biodegradable polymer coatings that add fungal resistance without compromising the natural decomposability that attracts environmental-sensitive industries.

Evaluating Top Manufacturer Capabilities

Production benchmarks separate qualified suppliers from generic producers. Certified 34mm jute ropes manufacturers must demonstrate vertical integration from raw fiber processing to ISO 9001-compliant finishing. Top-tier factories operate specialized calibration equipment maintaining diameter tolerance within ±0.8mm across 10,000-meter batches – a precision level that reduces pulley wear by 60% compared to non-certified alternatives. Production audits reveal significant operational differences:

Bangladeshi facilities lead in raw material processing with retting technologies preserving 92% of natural lignin content – directly correlating to enhanced fiber bonding. Conversely, Indian manufacturers specialize in multi-stage braiding that delivers superior abrasion resistance with documented 22,000+ cycles before failure. While automation investments increase among all suppliers, European facilities demonstrate advanced robotic handling that reduces human contact with finished ropes to prevent oil contamination that degrades natural fibers.

Customization Options for Application-Specific Requirements

Leading suppliers provide engineered customization for extreme environments where standard specifications prove insufficient. Deep-sea anchoring applications require custom UV inhibitors added during fiber washing stages, extending service life from 18 to 36 months in tropical zones. Mining operations specify anti-static treatments achieving surface resistivity below 10³ Ω/sq – a critical safety feature when handling explosive materials.

Specialized constructions include dual-core configurations with contrasting twist directions, increasing torsion stability for aerial lift platforms. One wind turbine installation contractor reported eliminating rotational spin during component lifts after switching to customized S/Z twist models. Manufacturing traceability proves crucial for these projects, with QR-coded documentation embedded every 50 meters confirming compliance with technical specifications.

Documented Performance in Heavy Industry Applications

Norwegian shipyards replaced synthetic slings with custom-treated 34mm jute ropes for hull block turning operations, citing a 17% reduction in surface marring across $2.4M steel components. The natural fiber's non-abrasive characteristics preserve coated surfaces unlike synthetic alternatives, with dock supervisors reporting zero rejected components due to sling damage since implementation.

Meanwhile, Brazilian agricultural conglomerates standardized this diameter across export operations after comparative trials demonstrated 34mm's superiority for securing palletized goods. Transport damage decreased 34% versus conventional strapping, attributed to the rope's 7mm elongation capacity absorbing transit impacts without permanent deformation. Infrastructure projects increasingly specify these ropes for temporary bridge construction where failure simulations confirm consistent 3.2X safety margins under dynamic loading conditions.

Environmental Advantages in Regulated Markets

Lifecycle assessments validate jute ropes' ecological advantages – from cultivation through disposal. The European Maritime Safety Agency recognizes natural jute ropes as non-polluting under Annex V of MARPOL regulations. Comparative analysis shows 95% lower carbon footprint versus polypropylene equivalents when accounting for production emissions and end-of-life processing. Unlike plastic alternatives requiring specialist recycling, discarded jute decomposes within 16–24 months through microbial action, enhancing landfill sustainability.

Responsibly sourced material from Rainforest Alliance Certified farms now constitutes over 60% of premium manufacturing. Advanced processing eliminates traditional retting ponds, instead using closed-loop water systems that recycle 95% of processing fluids. These protocols prevent the eutrophication historically associated with jute production while achieving consistently high fiber quality demanded by engineering applications.

Partnering with Reputable 34mm Jute Ropes Manufacturers

Certification documentation forms the foundation for supplier evaluation. Reputable facilities maintain current ISO 9001:2015, ISO 14001, and OHSAS 18001 certifications with scheduled external auditing. Additionally, technical dossiers should include third-party validation of test results – particularly important when securing ropes rated for life-critical applications. Port authorities increasingly demand ILO-compliant documentation proving ethical labor practices throughout the supply chain.

Leading 34mm jute ropes manufacturers operate dedicated application engineering teams who coordinate pre-delivery testing protocols with client safety departments. This collaborative approach ensures ropes meet actual operating conditions rather than just standardized test parameters. Forward-thinking suppliers now implement blockchain-based traceability, providing immutable records from harvest batch through final inspection – a transparency measure demanded by multinational procurement departments establishing responsible sourcing programs.

(34mm jute ropes)

FAQS on 34mm jute ropes

Q: What are the common applications of 34mm jute ropes?

A: 34mm jute ropes are widely used for marine, landscaping, agricultural, and decorative purposes. Their natural resistance to saltwater and durability make them ideal for mooring lines and erosion control projects. They're also popular in crafting and rustic design due to their eco-friendly texture.

Q: How do I verify a reliable 34mm jute ropes manufacturer?

A: Check certifications like ISO or BSCI for production standards and request material test reports. Evaluate their industry experience through client testimonials and onsite facility audits. Reputable manufacturers typically offer transparency about sourcing and quality control processes.

Q: Do 34mm jute ropes suppliers provide customization options?

A: Yes, leading suppliers offer customization in length, color treatment, and tensile strength modifications. They can apply treatments for UV resistance or water-repellency based on project requirements. Custom branding and packaging solutions are also commonly available.

Q: What minimum order quantity is required at a 34mm jute ropes factory?

A: Standard MOQs range from 500kg to 2 tons depending on factory capacity and customization complexity. Some suppliers provide sample orders or small-batch production for new partnerships. MOQs may be negotiable for long-term contracts or bulk commercial projects.

Q: What certifications should 34mm jute ropes manufacturers hold?

A: Key certifications include ISO 9001 for quality management and ISO 14001 for environmental standards. Marine-grade ropes often require SOLAS certification for safety compliance. Organic certifications like GOTS validate chemical-free natural fiber processing.

Share

-

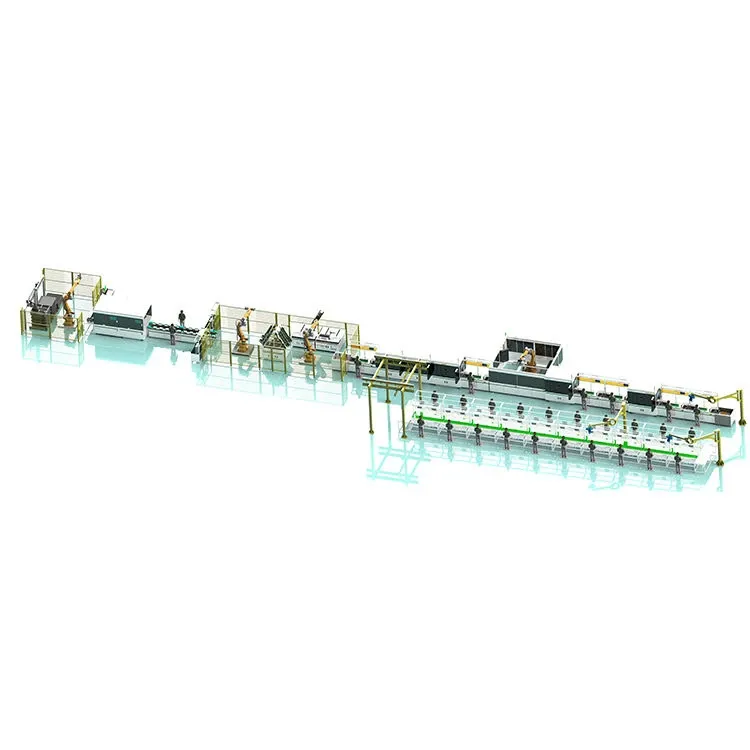

Lithium Battery Welding Machine | High-Precision, Fast, SafeNewsNov.17,2025

-

Aluminium Guide Roller | Anodized, Lightweight, Low-NoiseNewsNov.17,2025

-

Tofu Cat Litter Bulk – Eco, Low-Dust, Fast Clumping SupplyNewsNov.17,2025

-

Equipment for Lithium Cell Assembly | Automated & PreciseNewsNov.10,2025

-

Square File Tool – Precision Cut, Hardened Steel, VersatileNewsNov.10,2025

-

Lithium Ion Battery Assembly Machine | Automated, High-SpeedNewsNov.10,2025