ມ.ກ. . 09 , 2025 10:40

Back to list

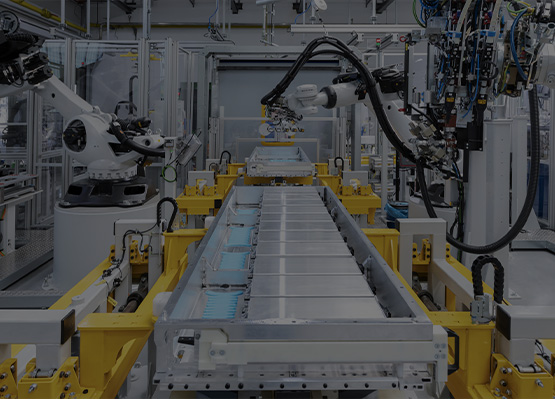

SD750-W1100-ZQFully automatic roller press slitting machine

Investing in an automatic high-speed roll-to-roll slitting machine revolutionizes industrial processes by merging precision with efficiency. Drawing from extensive industry expertise, this machine elevates production capabilities, embodying a pinnacle of technological advancement tailored for firms seeking to optimize their slitting procedures.

A significant contributor to its appeal is its customization capability. Businesses can tailor the machine’s features to their specific needs, whether requiring advanced tension control, unique slitting width, or handling different substrates. This versatility translates into unparalleled flexibility, allowing companies to venture into diverse production horizons without needing multiple machines. Navigating the maintenance landscape reveals ease and convenience, as the machine's design simplifies regular upkeep. Comprehensive support and readily available spare parts ensure that any technical hiccup is swiftly addressed, reinforcing the machine's status as a wise long-term investment. Lastly, environmental considerations are at the forefront of its design philosophy, with energy-efficient systems that reduce power consumption and assure sustainable operation. As industries shift towards greener operations, this machine aligns seamlessly with eco-friendly practices, positioning businesses as responsible leaders in their respective fields. Implementing an automatic high-speed roll-to-roll slitting machine is not merely an equipment upgrade; it's a strategic enhancement to operational prowess. Its role in refining manufacturing processes, coupled with its robust, adaptable, and sustainable nature, makes it an essential asset for businesses aiming to lead in quality and efficiency. Experts within the field endorse its efficacy, establishing it as the benchmark against which slitting excellence is measured.

A significant contributor to its appeal is its customization capability. Businesses can tailor the machine’s features to their specific needs, whether requiring advanced tension control, unique slitting width, or handling different substrates. This versatility translates into unparalleled flexibility, allowing companies to venture into diverse production horizons without needing multiple machines. Navigating the maintenance landscape reveals ease and convenience, as the machine's design simplifies regular upkeep. Comprehensive support and readily available spare parts ensure that any technical hiccup is swiftly addressed, reinforcing the machine's status as a wise long-term investment. Lastly, environmental considerations are at the forefront of its design philosophy, with energy-efficient systems that reduce power consumption and assure sustainable operation. As industries shift towards greener operations, this machine aligns seamlessly with eco-friendly practices, positioning businesses as responsible leaders in their respective fields. Implementing an automatic high-speed roll-to-roll slitting machine is not merely an equipment upgrade; it's a strategic enhancement to operational prowess. Its role in refining manufacturing processes, coupled with its robust, adaptable, and sustainable nature, makes it an essential asset for businesses aiming to lead in quality and efficiency. Experts within the field endorse its efficacy, establishing it as the benchmark against which slitting excellence is measured.

Share

Latest news

-

The Ultimate Guide to Square Files for Precision WorkNewsJun.26,2025

-

The Power of Flat FilesNewsJun.26,2025

-

Revolutionize Your Craft with High-Performance Rotary FilesNewsJun.26,2025

-

Precision and Durability with Diamond-Coated Needle FilesNewsJun.26,2025

-

Essential Tools for Precision Work: Round Metal Files and MoreNewsJun.26,2025

-

Essential Tools for Precision Sharpening: Triangular FilesNewsJun.26,2025