Exploring the Impact of Squaring File Production on Manufacturing Efficiency and Quality

The Impact of Squaring File Factories on Modern Manufacturing

In the realm of manufacturing, precision and efficiency are paramount. One key aspect that has significantly contributed to achieving these goals is the development and utilization of squaring file factories. These specialized production facilities focus on the creation of squaring files, which are essential tools in various industries for shaping, finishing, and polishing materials. This article delves into the significance of squaring file factories, their manufacturing processes, and their impact on modern manufacturing.

Understanding Squaring Files

Squaring files, also known as flat files, feature a flat surface with sharp edges that are used to smooth out rough edges, angles, and surfaces of materials such as metal, wood, and plastics. They come in various shapes and sizes, catering to a wide range of applications. The importance of squaring files cannot be understated; they are instrumental in the fine-tuning of parts in mechanical engineering, carpentry, and intricate crafting. Their precision enables manufacturers to achieve tight tolerances and smooth finishes, enhancing the overall quality of the final product.

The Manufacturing Process of Squaring Files

The production process of squaring files is a complex endeavor that requires precision and expertise

. It typically involves several stages1. Material Selection High-carbon steel is the most common material used due to its hardness and durability. Manufacturers must carefully select the steel grade to ensure optimal performance and longevity of the files.

2. Cutting and Shaping The raw steel is cut into the desired dimensions. This initial shaping is a crucial step; if not done correctly, it can affect the file's effectiveness.

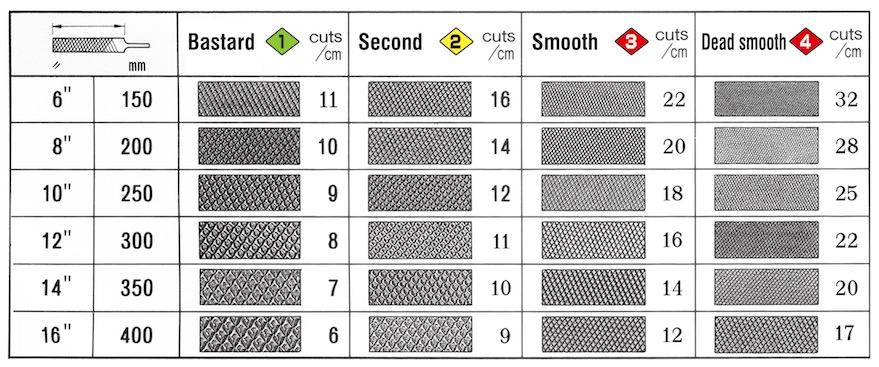

3. Toothing This process involves creating the file's characteristic teeth. The teeth are meticulously designed and arranged depending on the intended use of the file—whether for rough cutting or finishing. This step is vital for determining the file's cutting efficiency.

4. Hardening After toothing, the files undergo a hardening process where they are heated to high temperatures and then rapidly cooled. This step increases the hardness of the steel, making the files more effective at cutting and shaping materials.

squaring file factories

5. Finishing Touches Finally, the files are subjected to various finishing processes, which may include polishing and applying protective coatings to enhance durability and corrosion resistance.

The Role of Squaring File Factories in the Supply Chain

Squaring file factories play a critical role in the manufacturing supply chain. Their ability to produce high-quality files in bulk helps manufacturers maintain production efficiency. By ensuring an adequate supply of reliable tools, these factories contribute to the overall productivity of various sectors, including automotive, aerospace, and construction.

Moreover, these factories often leverage advanced manufacturing technologies. Automation and computer numerical control (CNC) machines have revolutionized the way files are produced, allowing for greater precision and consistency. With these advancements, squaring file manufacturers can meet the growing demand for specialized tools required in modern engineering applications.

Sustainability and Innovation

In recent years, there has been a growing trend in focusing on sustainability within manufacturing. Squaring file factories are also embracing this shift. Many manufacturers are exploring eco-friendly materials and processes to reduce their carbon footprint. For example, some are investigating alternatives to traditional steel that offer comparable durability with less environmental impact.

Additionally, innovation in file design continues to evolve. Manufacturers are developing files with unique tooth patterns and ergonomic handles, improving user comfort and efficiency. As industries embrace new technologies and methodologies, squaring file factories must keep pace to remain relevant and competitive.

Conclusion

Squaring file factories are an essential component of modern manufacturing, providing precision tools necessary for high-quality production. Their role in the supply chain enhances efficiency across various industries, while advances in technology and a focus on sustainability pave the way for future innovations. As the manufacturing landscape continues to evolve, the importance of these factories remains steadfast, underscoring their contribution to the quality and efficacy of products we rely on daily. The evolution of squaring files will undoubtedly play a crucial role in shaping the future of manufacturing practices, ensuring that both quality and sustainability are prioritized.

Share

-

The Best Lubricants for Aluminum Roller GuidesNewsJul.23,2025

-

Slitting Machine Applications in the Packaging IndustryNewsJul.23,2025

-

Rolling Roller Balancing Techniques for Smooth OperationNewsJul.23,2025

-

How To Optimize An EV Battery Assembly LineNewsJul.23,2025

-

Energy Efficiency in Modern Battery Formation EquipmentNewsJul.23,2025

-

Automation Trends in Pouch Cell Assembly EquipmentNewsJul.23,2025