Advanced Lithium Cell Machinery: High-Efficiency Battery Production

Industry Trends and the Imperative for Advanced Production Equipment

The global shift towards sustainable energy solutions is catalyzing unprecedented growth in the lithium-ion battery market. Driven by the rapid expansion of electric vehicles (EVs), sophisticated energy storage systems (ESS), and advanced portable electronics, demand for high-performance, reliable, and cost-effective lithium-ion batteries is soaring. This surge has, in turn, created a critical need for cutting-edge lithium cell machinery that can deliver precision, efficiency, and scalability in manufacturing. Manufacturers are increasingly seeking fully automated production lines capable of mass-producing battery packs with stringent quality controls, reduced operational costs, and rapid time-to-market. The industry trend clearly points towards integrated, intelligent, and highly flexible manufacturing solutions that can adapt to evolving battery chemistries and pack designs.

Innovation in battery technology, from solid-state to advanced silicon anodes, necessitates production equipment that is not only robust but also highly adaptable. This is where advanced lithium ion battery production equipment plays a pivotal role. The competitive landscape demands not just speed but also the meticulous precision required for critical processes like cell sorting, welding, and module assembly, ensuring optimal battery performance and longevity. As a result, investment in sophisticated automation and digital twin technologies for predictive maintenance and real-time process optimization is becoming standard for leading battery assembly line manufacturers.

Detailed Process Flow: Advanced Lithium Battery PACK Assembly

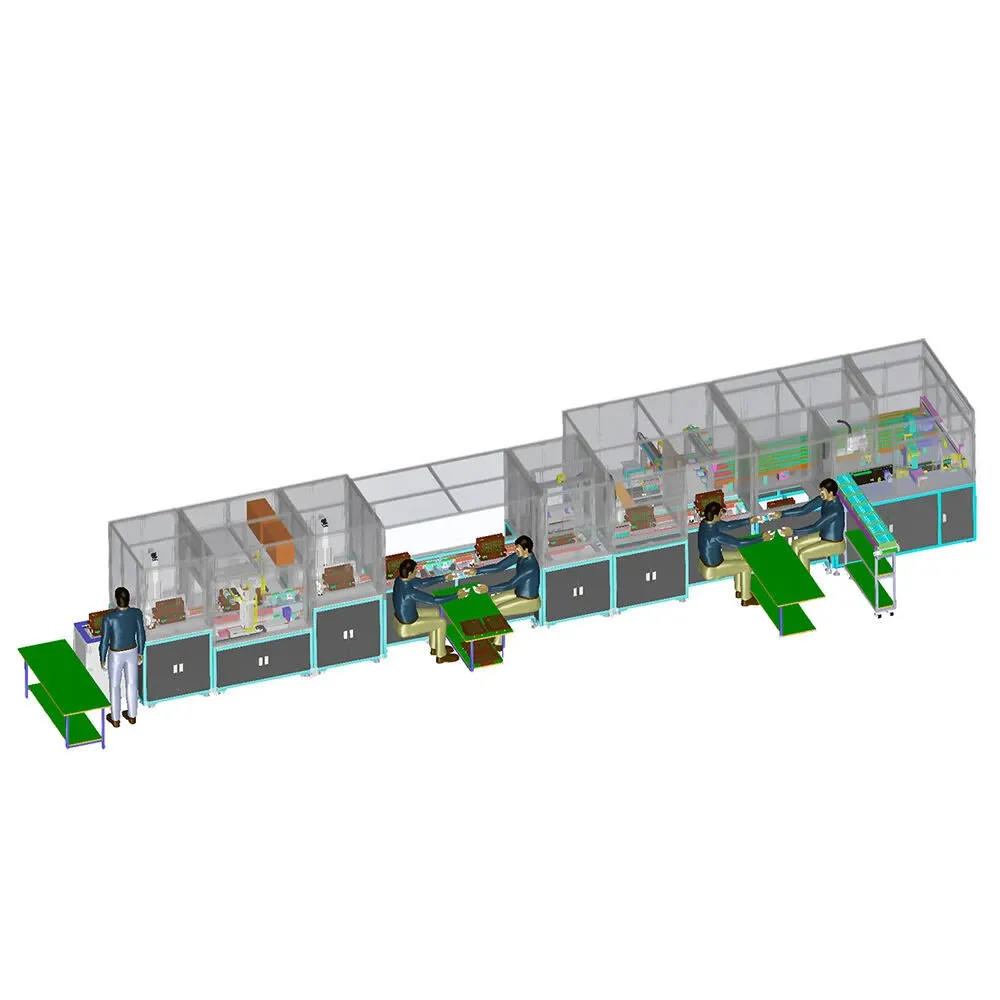

The manufacturing process for an Advanced New Energy Lithium Battery PACK Automated Assembly Production Line System is a multi-stage, highly precise operation. It transforms individual battery cells into fully functional, robust battery packs, adhering to stringent performance and safety standards. Each step is critical and requires specialized lithium cell machinery and automated systems.

Schematic Process Steps:

1. Cell Incoming Inspection & Sorting

(Voltage, IR, Capacity)

2. Module Assembly & Busbar Welding

(Laser/Spot Welding)

3. BMS Integration & Wiring

(Communication, Protection)

4. PACK Housing Assembly & Sealing

(Thermal Management, IP Rating)

5. End-of-Line Testing & Quality Control

(Performance, Safety, Certification)

- Product Materials & Manufacturing Processes: The production line handles various battery cell types (cylindrical, prismatic, pouch) and a range of materials including nickel-plated steel for busbars, high-strength aluminum alloys for PACK housings, and advanced polymer composites for insulation and thermal management. Manufacturing processes within the line encompass automated material feeding, robotic pick-and-place, precision laser welding (for busbar connections), ultrasonic welding, automated screwing and fastening, dispensing (thermal paste, adhesives), and vacuum sealing. The line is designed for high repeatability and accuracy, crucial for the long-term reliability of battery packs.

- Testing Standards & Quality Assurance: Our lithium cell machinery integrates comprehensive in-line and end-of-line testing. Key standards include ISO 12405 (Electric propulsion vehicles – Test specification for lithium-ion traction battery packs and systems), IEC 62619 (Secondary cells and batteries containing alkaline or other non-acid electrolytes – Safety requirements for secondary lithium cells and batteries for industrial applications), and UN/DOT 38.3 (Transport of dangerous goods). Automated vision systems check for welding defects, component placement accuracy, and foreign object detection. Electrical tests verify voltage, current, internal resistance, insulation resistance, and cell balancing functionality, ensuring compliance with specified performance parameters and international safety norms.

- Service Life & Durability: The robust construction of the lithium ion battery assembly line components ensures a long service life, typically exceeding 10-15 years with proper maintenance. Critical components like robotic arms, laser welders, and precision feeders are selected for industrial-grade durability and high MTBF (Mean Time Between Failures). Automated lubrication systems and predictive maintenance protocols further extend the lifespan and operational uptime.

- Target Industries: While the machinery's direct customers are battery manufacturers, the ultimate applications of the produced battery packs span a vast array of high-growth sectors:

- Electric Vehicles (EVs): Powering passenger cars, commercial vehicles, and electric buses.

- Energy Storage Systems (ESS): Grid-scale storage, residential and commercial backup power, and renewable energy integration.

- Industrial Applications: Robotics, AGVs (Automated Guided Vehicles), forklifts, and specialized machinery.

- Portable Electronics: High-capacity batteries for laptops, power tools, and drones.

- Marine & Aerospace: Electric propulsion and auxiliary power for specialized vessels and aircraft.

- Advantages in Typical Application Scenarios: Our advanced production line offers significant advantages such as superior energy conversion efficiency due to optimized connections, enhanced corrosion resistance through proper sealing and material selection, and increased safety via precise BMS integration and robust mechanical design. These factors contribute to extended battery pack life and reliable operation in demanding environments.

Technical Specifications & Key Parameters

Our advanced lithium ion battery assembly machine embodies state-of-the-art engineering, designed for maximum throughput, precision, and flexibility. The system integrates intelligent control, advanced robotics, and comprehensive data analytics to ensure optimal battery pack quality and operational efficiency. Below are typical specifications for our Advanced New Energy Lithium Battery PACK Automated Assembly Production Line System.

Product Specification Table: Advanced Lithium Battery PACK Assembly Line

| Parameter | Specification | Notes |

|---|---|---|

| Production Capacity | Up to 200,000 PACKs/year (configurable) | Based on 60kWh PACK, 2 shifts/day |

| Cell Compatibility | Cylindrical (18650, 21700, 4680), Prismatic, Pouch | Flexible jigging and tooling |

| Automation Level | Semi-automated to Full Automation (L4) | Robotics, AGVs, MES integration |

| Welding Technology | High-speed Laser Welding / Spot Welding | Real-time weld quality monitoring |

| Precision & Accuracy | ±0.05 mm (component placement) | Vision-guided robotics |

| Yield Rate | ≥ 99.5% | Achievable with optimal cell quality & maintenance |

| Traceability | Full cradle-to-grave cell-level traceability | MES integration with QR/barcode scanning |

| Safety Features | Emergency stops, interlocking doors, fire suppression, gas detection | Designed to ISO 13849 PL-d, CE certified |

| Operating Environment | Temperature: 10-30°C, Humidity: 40-70% RH | Controlled environment recommended |

Application Scenarios for Lithium Battery PACK Production Lines

The versatility and high-performance capabilities of our automated lithium cell machinery allow for its deployment across a broad spectrum of critical applications. The demand for robust, reliable, and energy-dense battery packs transcends various industries, each presenting unique challenges and requirements that our production lines are engineered to meet.

- Electric Vehicle (EV) Manufacturing: This is arguably the largest and most demanding application. Our battery assembly lines are instrumental in producing high-voltage, high-capacity battery packs for all types of EVs, including passenger cars, electric buses, trucks, and specialty vehicles. The machinery ensures consistent cell balancing, precise welding of busbars, robust thermal management system integration, and seamless Battery Management System (BMS) wiring, all critical for vehicle range, safety, and longevity.

- Energy Storage Systems (ESS): From utility-scale grid stabilization and peak shaving to residential solar energy storage, ESS requires large-format, modular battery packs. Our lithium cell machinery is designed to handle varying cell configurations and achieve high energy density while maintaining strict safety protocols for long-duration cycling and extreme operating conditions. Integration with power conversion systems (PCS) and grid infrastructure demands highly reliable and certified battery solutions.

- Consumer Electronics & Power Tools: While typically smaller in scale, high-volume production for laptops, drones, and high-performance power tools requires speed, compact design capabilities, and cost-effectiveness. Our specialized lithium ion battery assembly machine configurations cater to these specific needs, ensuring rapid assembly of smaller form-factor packs with exceptional quality control to prevent issues like swelling or premature degradation.

- Industrial Robotics & AGVs: The rise of automation in manufacturing and logistics hinges on dependable mobile power. Battery packs for Autonomous Guided Vehicles (AGVs) and industrial robots must endure high charge/discharge cycles, offer quick charging capabilities, and operate reliably in harsh industrial environments. Our production lines ensure the durability and performance necessary for these continuous operation applications.

- Medical Devices: Precision and unwavering reliability are paramount in medical applications. Our production lines can be tailored to meet the strict quality and traceability requirements for battery packs used in portable medical equipment, ensuring patient safety and device functionality.

Technical Advantages of Our Advanced Production Lines

Our Advanced New Energy Lithium Battery PACK Automated Assembly Production Line System offers distinct technical advantages that set it apart in a competitive market, ensuring superior product quality, operational efficiency, and long-term value for battery assembly line manufacturers.

- Unparalleled Automation & Robotics Integration: Our lines feature advanced collaborative robots (cobots) and industrial robotic arms for high-precision tasks such as cell handling, busbar welding, and complex component assembly. This significantly reduces manual labor, minimizes human error, and ensures consistent quality at high throughput rates. Full automation allows for 24/7 operation with minimal supervision.

- Superior Welding Precision and Quality: Employing state-of-the-art laser welding and resistance spot welding technologies, our systems achieve exceptionally strong, low-resistance connections between cells and busbars. Integrated real-time weld monitoring and quality verification systems ensure that every connection meets stringent electrical and mechanical specifications, preventing hot spots and maximizing battery lifespan.

- Comprehensive Digitalization & Traceability: Every cell and component's journey through the production process is meticulously recorded and traceable. Our Manufacturing Execution System (MES) integrates with ERP, capturing data on cell parameters, assembly steps, test results, and operator actions. This full "digital twin" of the battery pack ensures absolute traceability, crucial for warranty, safety recalls, and continuous process improvement.

- Modular and Flexible Design: The modular architecture of our lithium cell machinery allows for rapid configuration changes and scalability. This flexibility enables manufacturers to adapt to different cell formats (cylindrical, prismatic, pouch), varying pack designs, and evolving production volumes without extensive re-tooling or significant downtime.

- Integrated Quality Control & Testing: Beyond end-of-line testing, our lines incorporate in-line vision inspection, electrical testing (OCV, IR, insulation), and leak detection at multiple stages. This proactive approach identifies and rectifies potential defects early in the process, minimizing scrap rates and improving overall yield.

- Enhanced Safety Protocols: Given the inherent risks associated with lithium-ion battery production, our systems prioritize safety. Features include integrated fire suppression, hazardous gas detection, robust electrical isolation, and advanced interlocking safety gates conforming to international safety standards (e.g., ISO 13849).

- Energy Efficiency & Sustainability: Designed with energy-saving components and optimized process flows, our production lines minimize energy consumption. Furthermore, reduced material waste through precision manufacturing contributes to a more sustainable production footprint.

Vendor Comparison: Choosing Your Lithium Battery Assembly Partner

When evaluating providers of lithium cell machinery, B2B decision-makers face a critical choice. While many vendors offer baseline equipment, distinguishing factors lie in innovation, customization capabilities, comprehensive support, and proven track record. Our approach prioritizes a holistic solution, emphasizing long-term partnership over a transactional sale. Below is a comparative overview of key differentiating factors:

Lithium Ion Battery Production Equipment Comparison Factors

| Feature/Criterion | Standard Vendor Offerings | Our Advanced Solutions (Example) |

|---|---|---|

| Customization & Flexibility | Limited standard configurations, fixed cell types | Highly modular, supports multiple cell types and pack designs, future-proof for new chemistries |

| Automation Level | Basic automation for individual stations | Integrated full automation with advanced robotics, AGVs, MES Level 4 integration |

| Data Management & Traceability | Basic logging, limited component-level tracking | Full cell-to-pack traceability, real-time data analytics, cloud integration for predictive maintenance |

| After-Sales Support & Service | Standard warranty, reactive support, limited spare parts access | Proactive remote diagnostics, 24/7 technical support, comprehensive spare parts inventory, local service teams |

| System Integration | Proprietary interfaces, manual data transfer | Open architecture, OPC UA, seamless integration with existing factory systems (ERP, SCADA) |

| Safety & Compliance | Meets minimum local safety regulations | Global compliance (CE, UL, ISO), advanced risk mitigation, comprehensive safety features |

Our differentiation stems from a deep understanding of the battery manufacturing ecosystem and a commitment to providing solutions that not only meet today's demands but also anticipate future market shifts. We focus on engineering excellence, robust integration, and a customer-centric approach to support your production goals.

Customized Solutions and Engineering Expertise

Recognizing that no two battery manufacturers have identical requirements, our strength lies in providing highly customized lithium ion battery assembly line solutions. Our team of expert engineers collaborates closely with clients from initial concept to full deployment, ensuring that every aspect of the lithium cell machinery is optimized for their specific needs.

- Tailored to Your Specifications: Whether it's unique cell formats, specialized pack designs, specific throughput targets, or integration with existing factory infrastructure, we design and build production lines that precisely match your operational parameters. This includes custom jigging, robotic end-effectors, and software configurations.

- Scalability and Future-Proofing: Our modular design philosophy ensures that your investment can grow and adapt. Lines can be expanded with additional modules, updated with new technologies, or reconfigured to handle future battery chemistries and designs, protecting your capital expenditure.

- Turnkey Project Management: We offer end-to-end project management, encompassing design, manufacturing, installation, commissioning, and staff training. Our dedicated project managers ensure seamless execution, on-time delivery, and adherence to budget, minimizing disruption to your operations.

- Process Optimization Consultancy: Leveraging years of industry experience, our engineers provide valuable insights into optimizing your battery manufacturing processes, from material flow and quality control strategies to energy efficiency and lean manufacturing principles. This consultancy ensures that you gain maximum value from your automated system.

Application Case Studies & Client Success

Our commitment to delivering high-performance lithium cell machinery is validated by the success of our clients globally. We have partnered with leading manufacturers across various sectors to elevate their battery production capabilities.

- Case Study 1: Large-Scale EV Battery Manufacturer

A prominent global EV battery producer required a high-throughput, fully automated assembly line for their new generation of prismatic cells. Our solution provided an integrated line capable of producing 10 GWh/year of battery packs, significantly exceeding their previous semi-automated output by 300%. The implementation included advanced laser welding with 100% in-line quality inspection, resulting in a yield rate of 99.8% and a 40% reduction in labor costs for the PACK assembly segment. The client achieved ISO 9001 and IATF 16949 certification for the new production module within six months of commissioning.

- Case Study 2: Residential ESS Provider

A fast-growing residential energy storage company needed a flexible production line to handle multiple battery pack configurations for their diverse product portfolio. We designed a modular lithium ion battery assembly machine with quick-change tooling, enabling them to switch between different pack formats in under 30 minutes. The system's precise adhesive dispensing and sealing stations enhanced the IP rating of their battery enclosures, improving product durability and customer satisfaction. The client reported a 25% decrease in time-to-market for new ESS models.

- Case Study 3: Industrial Robotics & AGV Specialist

An innovator in industrial automation sought to insource battery pack production to gain better control over quality and supply chain. We delivered a compact yet highly efficient automated line for producing high-cycle-life battery packs for their AGVs. The system's integrated diagnostic tools allowed for granular performance tracking of each produced pack, enhancing their product reliability and reducing field service incidents by 15%. This strategic move also provided them with greater intellectual property protection for their proprietary battery designs.

Commitment to Expertise, Authoritativeness, and Trustworthiness ()

Our dedication to providing advanced lithium cell machinery is underpinned by a steadfast commitment to the highest industry standards, ensuring expertise, authoritativeness, and trustworthiness in every solution we deliver.

- Certifications and Partnerships: Our manufacturing processes and products are certified to international standards such as ISO 9001 for quality management and CE marking for European safety compliance. We actively participate in industry consortia and maintain strategic partnerships with leading component suppliers and research institutions, reinforcing our position as an authoritative voice in battery assembly technology.

- Years of Service & Client Trust: With over 15 years of specialized experience in automated manufacturing solutions, we have successfully delivered numerous complex projects for a global clientele, including many Fortune 500 companies in the new energy sector. This extensive track record demonstrates our profound experience and reliability.

- Data-Driven Validation: All performance claims are backed by rigorous internal testing, comprehensive factory acceptance tests (FAT), and site acceptance tests (SAT). We provide detailed test reports, throughput analyses, and yield rate data to ensure transparency and build client confidence.

Frequently Asked Questions (FAQ)

Q: What is the typical lead time for a full production line?

A: Lead times vary based on customization and complexity, typically ranging from 6 to 12 months from order confirmation to final commissioning. Project timelines are mutually agreed upon during the proposal phase.

Q: What kind of warranty do you offer on your equipment?

A: We offer a standard one-year warranty on parts and labor, extendable through service contracts. Our comprehensive warranty covers manufacturing defects and ensures operational integrity post-installation.

Q: How do you handle after-sales support and maintenance?

A: Our global support network provides 24/7 remote diagnostics, on-site technical assistance, and a readily available spare parts inventory. We also offer preventive maintenance programs and advanced training for your operational and maintenance staff.

Q: Can your lines integrate with our existing MES/ERP systems?

A: Yes, our systems are designed with open communication protocols (e.g., OPC UA, Modbus TCP) to ensure seamless integration with most standard MES and ERP platforms, providing real-time data exchange and control.

Conclusion

The future of energy is undeniably electric, and at the heart of this transformation is the advanced manufacturing of lithium-ion batteries. Our Advanced New Energy Lithium Battery PACK Automated Assembly Production Line System represents the pinnacle of lithium cell machinery, engineered to meet the escalating demands for efficiency, precision, and scalability. By combining cutting-edge automation, rigorous quality control, and a commitment to customized client solutions, we empower battery manufacturers to achieve unprecedented production targets and maintain a competitive edge in a rapidly evolving market. Investing in our technology means investing in a robust, reliable, and future-proof production partner.

References

- International Electrotechnical Commission (IEC) Standard 62619: Secondary cells and batteries containing alkaline or other non-acid electrolytes – Safety requirements for secondary lithium cells and batteries for industrial applications.

- International Organization for Standardization (ISO) Standard 12405: Electric propulsion vehicles – Test specification for lithium-ion traction battery packs and systems.

- United Nations Recommendations on the Transport of Dangerous Goods, Manual of Tests and Criteria (UN/DOT 38.3).

- International Organization for Standardization (ISO) Standard 9001: Quality management systems – Requirements.

- International Automotive Task Force (IATF) Standard 16949: Quality management system for automotive production and relevant service parts organizations.

Share

-

Lithium Battery Welding Machine | High-Precision, Fast, SafeNewsNov.17,2025

-

Aluminium Guide Roller | Anodized, Lightweight, Low-NoiseNewsNov.17,2025

-

Tofu Cat Litter Bulk – Eco, Low-Dust, Fast Clumping SupplyNewsNov.17,2025

-

Equipment for Lithium Cell Assembly | Automated & PreciseNewsNov.10,2025

-

Square File Tool – Precision Cut, Hardened Steel, VersatileNewsNov.10,2025

-

Lithium Ion Battery Assembly Machine | Automated, High-SpeedNewsNov.10,2025