Lithium Ion Battery Assembly Machine | High-Speed, Precise

A Field Note on the Lithium Battery Boom and the Machines Behind It

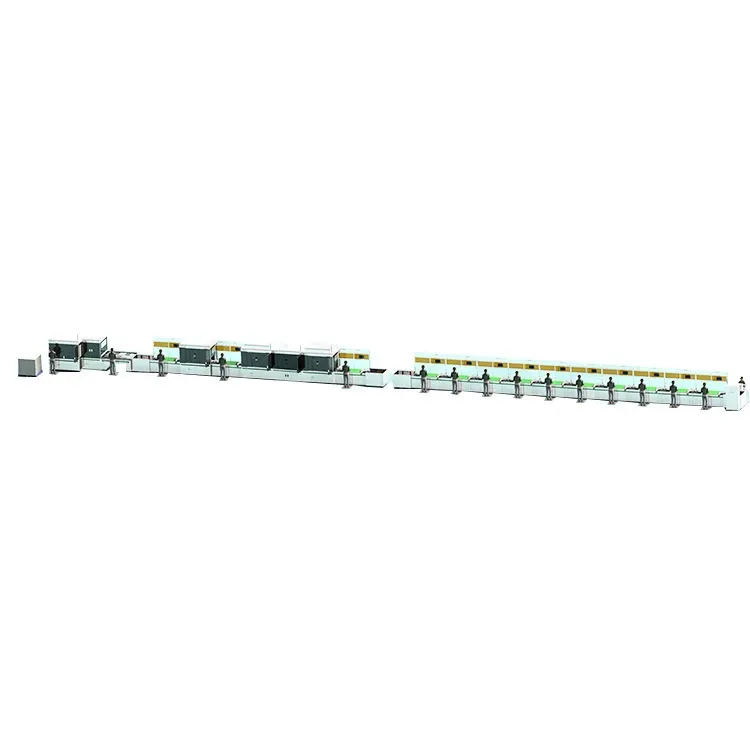

If you’ve toured a modern pack factory lately, you know the heartbeat is the Lithium Ion Battery Assembly Machine. I’ve walked a few of these lines; the rhythm is oddly calming—cells shuttling in, lasers stitching tabs in bright pinpoints, MES screens quietly logging each weld. And yes, the small details decide everything.

Industry pulse and what’s actually changing

Demand is shifting from just EV packs to LEVs, home storage, power tools and, surprisingly, garden equipment—where uptime is a religion. Cycle-time targets have tightened (≈8–15 packs/min, real-world use may vary), and traceability is no longer a nice-to-have. Many customers say they want AI vision to stop human error early, and to be honest, they’re right. Standards pressure (UN 38.3, IEC 62133, UL 2580) quietly dictates how machines are built and validated.

Process flow: materials, methods, and the gritty details

The Battery Pack Automated Assembly Production Line handles over 90% of cylindrical cells (18650/21700/26650). Typical flow: manual feeding → OCV sorting and scanning → secondary scan (traceability) → manual insertion into brackets → AI polarity detection → NG station (auto reject) → A‑side laser welding → automatic fixture plate flipping (or, on certain layouts, unique double‑sided cross spot welding for one‑pass welds) → B‑side laser welding → manual fixture disassembly. Materials: nickel strip ≈0.10–0.20 mm, steel/aluminum brackets, standard heat‑resistant fixtures. Methods: Class‑1 enclosed fiber laser, real‑time power feedback, weld pull‑test sampling per lot, ESD‑safe conveyance. Testing standards referenced include IEC 62133 safety, UN 38.3 transport, and internal weld pull ≥5 N/cell tab (typical data: 6.2–7.8 N, Cpk > 1.33).

Product specifications (selected)

| Product name | Battery Pack Automated Assembly Production Line |

| Supported cells | Cylindrical 18650/21700/26650 (others on request) |

| Throughput | ≈8–15 packs/min (layout- and pack‑dependent) |

| OCV sorting accuracy | ±2 mV typical; AI polarity accuracy ≈99.8% |

| Welding | Laser spot welding; optional double‑sided cross weld (one‑pass) |

| Traceability | 1D/2D barcode scan, MES/ERP integration, lot genealogy |

| Service life | Design life 7–10 years; MCBF ≥2,000,000 cycles; uptime ≈98.5% |

| Certifications (typical) | ISO 9001 line build; laser safety IEC 60825‑1; clean handling ISO 14644‑1 class guidance |

| Origin | Room 1410, No. 119 Zhongxing East Street, Xiangdu District, Xingtai, Hebei, China |

Where it’s used (and why)

- LEV/e‑bike packs, power tools, smart home storage, AGV batteries, medical carts (with validation), and industrial IoT. Advantages include low rework (AI polarity), consistent weld energy, and fast changeover. In fact, customers tell me the one‑pass cross weld saves hours per week on fixtures.

Vendor snapshot (indicative)

| Vendor | Strengths | Trade‑offs |

|---|---|---|

| XT Shuoding | High standardization for cylindrical packs; double‑sided cross welding; pragmatic MES | Best fit for cylindrical; prismatic/pouch need customization |

| Vendor M (global) | Large install base; deep global service | Longer lead times; premium pricing |

| Vendor L (regional) | Agile customization; quick spares | Documentation maturity varies; fewer turnkey references |

Customization, service, and real feedback

Options include cell format jigs, nickel strip thickness, fixture pitch, and laser power profiles. FAT/SAT with pull‑test sampling, continuity checks (≤10 mΩ joint resistance), and ESD audits are standard. One European e‑bike maker reported 23% cycle‑time improvement and a 0.6% drop in NG after enabling AI polarity + secondary scan. Another customer in tools said the Lithium Ion Battery Assembly Machine cut manual rework by “half a shift per week”—not scientific, but telling.

Why this Lithium Ion Battery Assembly Machine stands out

The double‑sided cross spot welding (where applicable) is the surprise—one‑time welding without flipping can shave seconds and reduce fixture wear. And the line’s standardization across 18650/21700 is, frankly, what makes ramp‑ups less painful.

Authoritative references

- [1] IEC 62133‑2: Safety requirements for portable sealed secondary lithium cells and batteries — https://webstore.iec.ch

- [2] UN 38.3: UN Manual of Tests and Criteria, lithium battery transport — https://unece.org

- [3] UL 2580: Batteries for use in electric vehicles — https://www.ul.com

- [4] ISO 14644‑1: Cleanrooms and associated controlled environments — https://www.iso.org

- [5] IEC 60825‑1: Laser product safety — https://webstore.iec.ch

Share

-

Lithium Battery Welding Machine | High-Precision, Fast, SafeNewsNov.17,2025

-

Aluminium Guide Roller | Anodized, Lightweight, Low-NoiseNewsNov.17,2025

-

Tofu Cat Litter Bulk – Eco, Low-Dust, Fast Clumping SupplyNewsNov.17,2025

-

Equipment for Lithium Cell Assembly | Automated & PreciseNewsNov.10,2025

-

Square File Tool – Precision Cut, Hardened Steel, VersatileNewsNov.10,2025

-

Lithium Ion Battery Assembly Machine | Automated, High-SpeedNewsNov.10,2025