Advanced Cylindrical Cell Production with AI

Cylindrical cell manufacturing is a core process driving innovations in lithium-ion battery technology. As industries such as electric vehicles, energy storage, consumer electronics, and grid applications continue to boom, the precision, scalability, and performance of cylindrical cell manufacturing processes have never been more crucial. This guide analyzes the cylindrical cell manufacturing process, assembly techniques, cutting-edge production lines, technical standards, and showcases the 18650, 21700, 26650, 32650 Cylindrical Cell Production Line as a leading industry solution.

1. Industry Trends in Cylindrical Cell Manufacturing

The global cylindrical cell market is witnessing robust growth, driven by soaring demand for electric mobility, grid-level batteries, portable electronics, and industrial backup systems. According to MarketsandMarkets, the lithium-ion cylindrical cell market is projected to reach $73 billion by 2027 at a CAGR of over 14%. The transition from traditional 18650 cells to higher energy-density formats (21700, 26650, 32650) is primarily due to the need for longer runtime, improved thermal stability, and cost efficiency.

2. Key Technical Parameters of Cylindrical Cell Manufacturing

| Parameter | 18650 | 21700 | 26650 | 32650 |

|---|---|---|---|---|

| Dimensions (mm) | 18 × 65 | 21 × 70 | 26 × 65 | 32 × 65 |

| Typical Capacity (Ah) | 2.0–3.5 | 4.0–5.0 | 5.0–6.0 | 6.0–7.5 |

| Nominal Voltage (V) | 3.6 / 3.7 | 3.6 / 3.7 | 3.6 / 3.7 | 3.2 / 3.7 |

| Cycle Life (80% DOD) | 800–1,500 | 1,000–2,000 | 1,000–2,200 | 2,000–4,000 |

| Shell Material | Nickel-plated steel Aluminum |

Nickel-plated steel Aluminum |

Aluminum alloy | Aluminum alloy |

| ISO/ANSI Compliant | Yes | Yes | Yes | Yes |

| Energy Density (Wh/kg) | 180–230 | 200–250 | 180–210 | 165–190 |

Data: Compiled from major cell manufacturer datasheets (2023–2024)

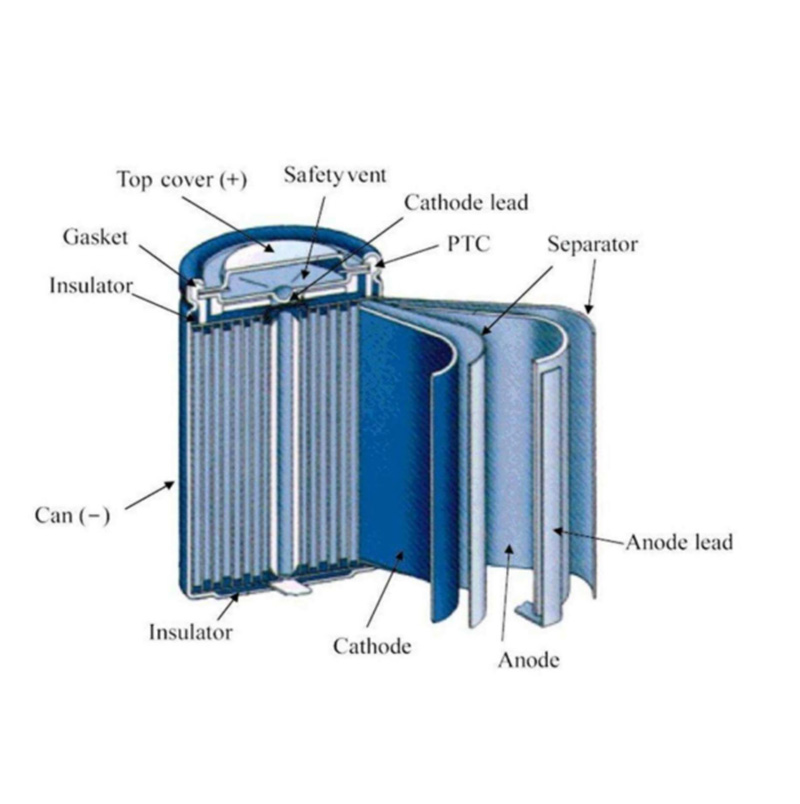

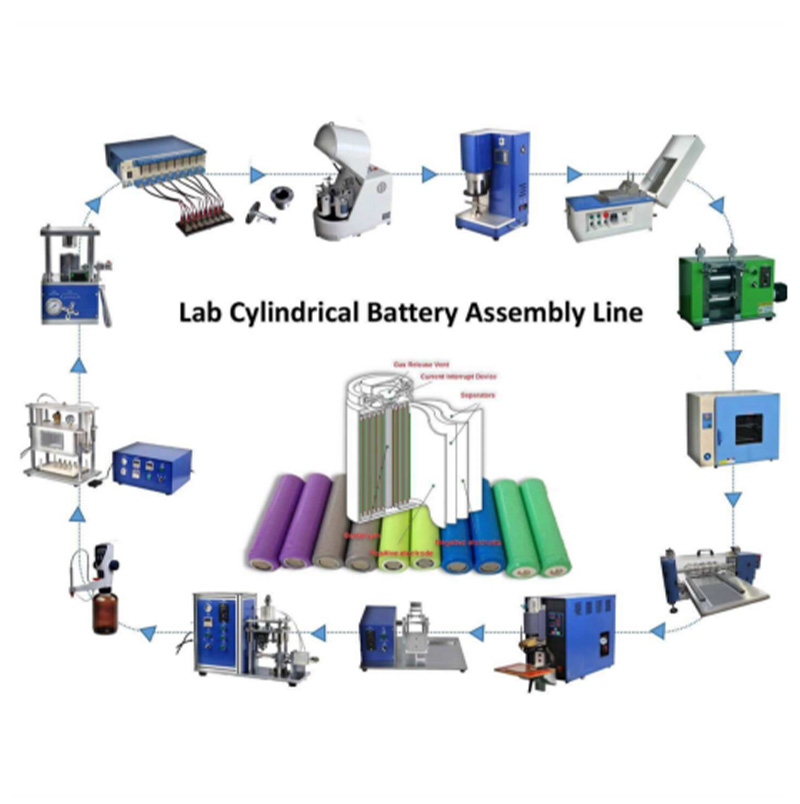

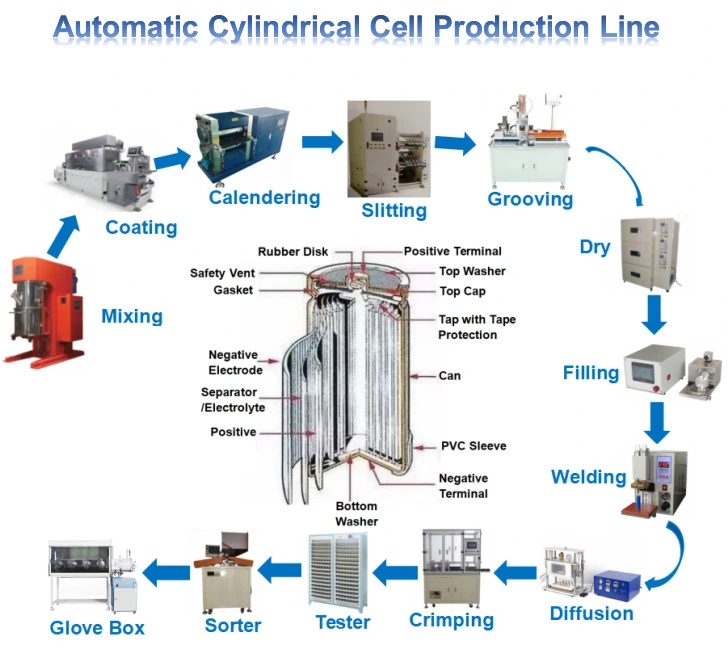

3. Cylindrical Cell Manufacturing Process Flow

Cathode/Anode slurry mixing, active material selection

Coating, drying, calendaring, slitting

Jelly roll formation

Inserting into cylindrical casing, welding

Vacuum filling, laser/crimp sealing

Initial charge, testing, cycling

ISO/ANSI inspection, grading

Each stage of cylindrical cell manufacturing is optimized for consistency, traceability, and maximum energy density. Processes such as CNC deep drawing and laser welding ensure dimensional stability and uniform performance across production batches. Quality control is enforced per ISO 9001, ANSI C18.2M, and UN 38.3 standards.

4. 18650 21700 26650 32650 Cylindrical Cell Production Line Overview

- Product Name: 18650 21700 26650 32650 Cylindrical Cell Production Line

- Official Link: cylindrical cell manufacturing production line

The XTShuoding automated cylindrical cell manufacturing line delivers integrated solutions for mass-producing cells in 18650, 21700, 26650, and 32650 sizes. Adopting modular architecture, advanced robotics, and AI-aided inspection, this line supports smart scheduling and real-time quality feedback, ensuring maximal throughput and yield.

5. Product Material, Processes & Compliance: Comparative Analysis

| Feature | XTShuoding 18650/21700/26650/32650 | Market Average |

|---|---|---|

| Shell Material | High-purity Aluminum Nickel-plated Steel (ISO 5832) |

Steel, Regular Aluminum |

| Manufacturing Process | CNC Deep Drawing, Automated Laser Welding, Germany-imported Rollers | Manual/Hybrid Rolling, Resistance Spot Welding |

| Capacity Uniformity | < ±2% | ±5%~±7% |

| Energy Density (Wh/kg) | Up to 250 | 180~220 |

| Batch Traceability | AI-based QR Code Tracking ISO 9001 Traceability |

Partial, Manual Logs |

| Inspection Standards | ISO 9001, ANSI C18.2M, UN 38.3, IEC 62133 | Selected (varies by region) |

| Service Life (Typical) | >2,000 cycles | 1,000~1,800 cycles |

| Application Versatility | EVs, ESS, Industrial, Medical | Consumer, Industrial |

| Corrosion Protection | 3-layer Anti-oxidant + Nanofilm Cathode (ISO 12944) | Single-layer Coating |

Materials are sourced in compliance with ISO 5832 for specialty metals, and all manufacturing adheres to RoHS and FDA environmental and safety standards. The result: robust cycle life, minimal leakage, low IR (Internal Resistance), and outstanding anti-corrosion performance even under harsh conditions such as petrochemical and metallurgical plants.

6. Industry Manufacturer Comparison: Who Leads the Cylindrical Cell Manufacturing Race?

| Feature | XTShuoding | Panasonic | Samsung SDI | LG Energy Solution |

|---|---|---|---|---|

| Automation Degree | Full (AI+Robotax+IIoT) | Semi-auto/Full | Full | Semi-auto/Full |

| Custom Cell Size | Yes | 18650, 21700 | All major | 18650, 21700, 26650 |

| Key Technology | CNC, AI Vision, Laser Sealing | Hybrid/Manual, Laser | Automated, AI QC | Laser, Roll-to-roll |

| ISO/ANSI Certified | Yes, ISO 9001, ANSI C18.2M | Yes | Yes | Yes |

| Warranty | 24 months | 18 months | 12–18 months | 18 months |

| Onsite Tech Support | Global 72h Response | Limited | Limited | Regional |

XTShuoding partners with CATL, BYD, ABB, Siemens, and supplies cell assembly lines to over 26 countries/regions with field-proven stability. All products are backed with two-year global warranty, ISO/ANSI compliance, and remote IIoT diagnosis.

7. Customization: Tailored Cylindrical Cell Manufacturing Process & Assembly Solutions

Every industry has specific needs. XTShuoding provides:

- Pre-sales technical consultation with battery engineers

- Flexible line configuration (capacity, modular upgrades, footprint)

- Support for diverse electrolyte types & specialty coatings

- OEM/ODM support: Logo, software, process parameters

- Compliance with FDA, RoHS, UN 38.3, and all mainstream ISO standards

8. Application Scenarios & Advantages of Advanced Cylindrical Cell Manufacturing

- Electric Vehicles (EVs): High cycle life, excellent thermal management, fast charge/discharge in 21700/26650 cells.

- Industrial ESS (Energy Storage Systems): 32650 cells ensure longevity, anti-corrosion, safety—crucial for solar+wind storage.

- Medical Devices: Precision manufacturing yields low-pulsation, high-reliability pack builds.

- Petrochemical/Metallurgy: Multi-layer coatings prevent corrosion, extend battery asset life in harsh, humid, or chemical-rich environments.

- Water Supply & Municipal: Stable emergency backup, certified under ISO 12944 for anti-corrosive applications.

- Consumer Electronics: Automation brings cost-down, performance-up scalability for mass developers.

Global Solar Farm in the UAE deployed a hybrid 21700/32650 line, enabled by XTShuoding's automated cylindrical cell manufacturing process. The solution delivered 99.7% OEE (Overall Equipment Effectiveness), reduced downtime by 60%, and, owing to nanofilm anti-corrosion, cut module maintenance costs by $150,000 per annum. (Source: batterydesign.net)

9. Client Feedback & Application Experience

- EV Battery Manufacturer, Germany: “The XTShuoding line’s AI inspection cut our QC false positives by half. Real-time reporting and compliance with ISO 9001/IEC 62133 standards built client trust.”

- Grid ESS Integrator, India: “Switching to fully automated cylindrical cell manufacturing let us triple throughput and reduce operator workload, maintaining consistent cell capacity within ±2% deviation.”

With fielded references in over 20 countries, and partnerships with global battery brand leaders, XTShuoding is positioned as a leading authorized supplier in the cylindrical cell manufacturing industry.

10. Delivery, Warranty, & Support

- Delivery Lead Time: Standard lines ship in 70–90 days; customized lines subject to requirements (firm schedule on PO)

- Warranty: 24 months (parts & labor), extendable with service contract

- After-sales Support: 24/7 remote troubleshooting + 72h global onsite support

- Spare Parts: Stocked for all wear items; predictive maintenance available via IIoT

- Training: Onsite and remote (English/Chinese)

All lines come with full compliance certification (ISO 9001, CE, ANSI C18.2M). Comprehensive Service Level Agreements (SLAs) are available.

11. Professional FAQs: Cylindrical Cell Manufacturing Terminology Explained

12. References & Further Reading

- BatteryDesign.net: Deep Dive into Cylindrical Cell Manufacturing Processes

- BatteryUniversity.com: Types of Battery Cells and Their Manufacturing

- Journal of Energy Storage: Recent Advances in Cylindrical Cell Design

- ResearchGate: Cylindrical Lithium-Ion Cell Assembly Automation Review

Share

-

Lithium Battery Welding Machine | High-Precision, Fast, SafeNewsNov.17,2025

-

Aluminium Guide Roller | Anodized, Lightweight, Low-NoiseNewsNov.17,2025

-

Tofu Cat Litter Bulk – Eco, Low-Dust, Fast Clumping SupplyNewsNov.17,2025

-

Equipment for Lithium Cell Assembly | Automated & PreciseNewsNov.10,2025

-

Square File Tool – Precision Cut, Hardened Steel, VersatileNewsNov.10,2025

-

Lithium Ion Battery Assembly Machine | Automated, High-SpeedNewsNov.10,2025