Battery Production Line Suppliers for High-Quality Assembly Solutions

The Rise of Battery Assembly Line Exporters A Key Player in the Global Market

In recent years, the global demand for batteries has surged, driven by the rapid advancement of technology in electric vehicles, renewable energy storage, and portable electronics. This growing market has led to a significant increase in battery assembly line exporters, which have become essential players in the global supply chain. These exporters provide not only the machinery and technology needed for efficient battery production but also contribute to the overall improvement of manufacturing processes worldwide.

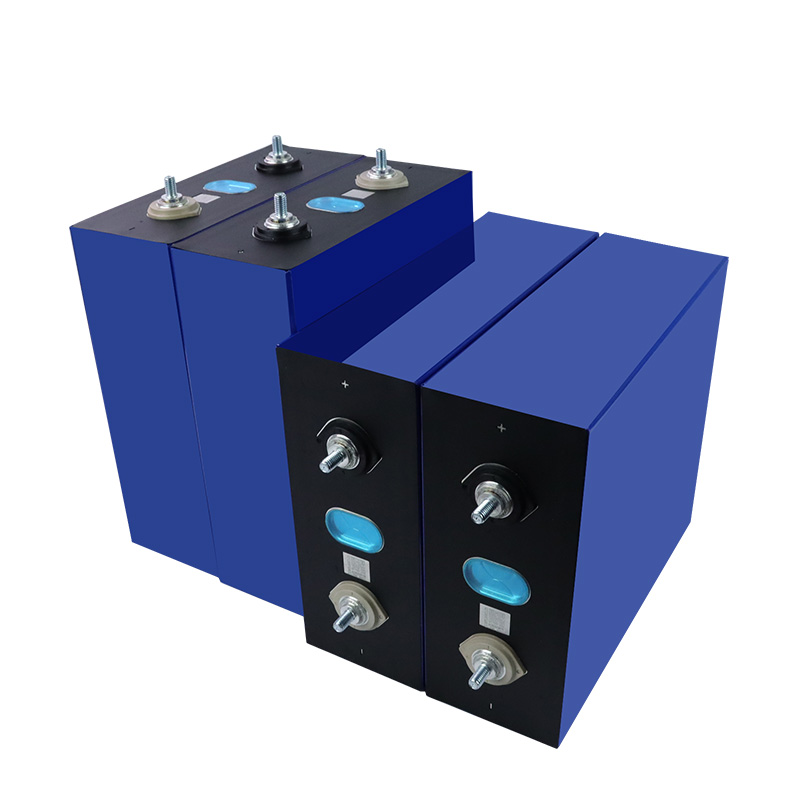

Battery assembly lines encompass a wide range of equipment and technologies designed to streamline the production of batteries, from cell assembly to final packaging. The assembly process typically involves several stages, including cell formation, module assembly, and quality control. Each of these stages requires specialized machinery and expertise, which battery assembly line exporters are well-equipped to provide. By exporting these assembly lines, manufacturers can enhance their production capabilities, ensuring that they meet the increasing demand for batteries.

One of the primary advantages of engaging with battery assembly line exporters is the access to cutting-edge technology. As the industry is characterized by rapid innovation, manufacturers benefit from the latest advancements in automation, robotics, and quality control systems. This technological edge enables them to produce batteries more efficiently, reducing production costs and lead times. Moreover, advanced technology contributes to improved product quality, ensuring that the batteries produced meet stringent industry standards.

battery assembly line exporters

Additionally, battery assembly line exporters often provide comprehensive support and training for manufacturers, ensuring a smooth transition to new production technology. This guidance includes everything from installation to maintenance and troubleshooting, allowing manufacturers to maximize their productivity and minimize downtime. The collaboration between exporters and local manufacturers fosters a deeper understanding of battery production processes and paves the way for continuous improvement.

Furthermore, the global push for sustainability and environment-friendly solutions is driving changes in battery manufacturing. Exporters are increasingly focusing on eco-friendly practices and materials, aligning with global standards for sustainability. This shift not only helps manufacturers comply with regulatory requirements but also appeals to environmentally conscious consumers. By providing assembly lines designed to minimize waste and energy consumption, battery assembly line exporters are playing a crucial role in promoting greener manufacturing practices.

The geographical distribution of battery assembly line exporters is also noteworthy. Emerging markets, particularly in Asia, have become hubs for battery manufacturing. Countries like China, South Korea, and Japan lead in both battery production and the export of assembly lines. These nations benefit from a robust supply chain, skilled labor force, and significant investments in research and development. As a result, they can offer competitive pricing and innovative solutions to meet the diverse needs of manufacturers worldwide.

In conclusion, the role of battery assembly line exporters in shaping the future of battery production cannot be overstated. By providing advanced technology, training, and support, these exporters are enabling manufacturers to enhance their production capabilities while meeting the growing global demand for batteries. As the industry continues to evolve, the collaboration between exporters and manufacturers will be vital in driving innovation, sustainability, and efficiency in battery production, solidifying their position as key players in the global market.

Share

-

The Best Lubricants for Aluminum Roller GuidesNewsJul.23,2025

-

Slitting Machine Applications in the Packaging IndustryNewsJul.23,2025

-

Rolling Roller Balancing Techniques for Smooth OperationNewsJul.23,2025

-

How To Optimize An EV Battery Assembly LineNewsJul.23,2025

-

Energy Efficiency in Modern Battery Formation EquipmentNewsJul.23,2025

-

Automation Trends in Pouch Cell Assembly EquipmentNewsJul.23,2025