Car Rubber Door Seals Manufacturers and Their Innovative Solutions for Enhanced Vehicle Performance

Exploring Rubber Door Seals for Cars Importance and Manufacturing Insights

Rubber door seals are a critical component in the automotive industry, playing a significant role in vehicle performance, comfort, and longevity. These seals are designed to enhance the sealing capabilities of car doors, ensuring that they close tightly and protect the interior of the vehicle from external elements. In this article, we will delve into the significance of rubber door seals, their manufacturing processes, and the factors that influence their quality.

Significance of Rubber Door Seals

The primary function of rubber door seals is to provide a tight barrier between the car door and the car body. This barrier is essential for several reasons. Firstly, it prevents water, dust, and noise from entering the car, contributing to a comfortable and enjoyable driving experience. Well-sealed doors help to maintain the vehicle's interior environment, safeguarding against dampness, which could lead to mold growth, and keeping road noise at bay.

Secondly, rubber door seals play a vital role in enhancing vehicle safety. In the event of a collision, proper sealing can help maintain the structural integrity of the vehicle, ensuring that the cabin remains as safe as possible. Effective seals also contribute to the efficiency of climate control systems by reducing the loss of heated or cooled air, thereby improving fuel efficiency.

Manufacturing Processes

Rubber door seals are typically manufactured using a combination of synthetic and natural rubber materials. The production process involves several key steps

1. Material Selection Manufacturers select suitable rubber compounds based on the desired properties, such as flexibility, durability, and resistance to environmental factors like UV radiation and extreme temperatures.

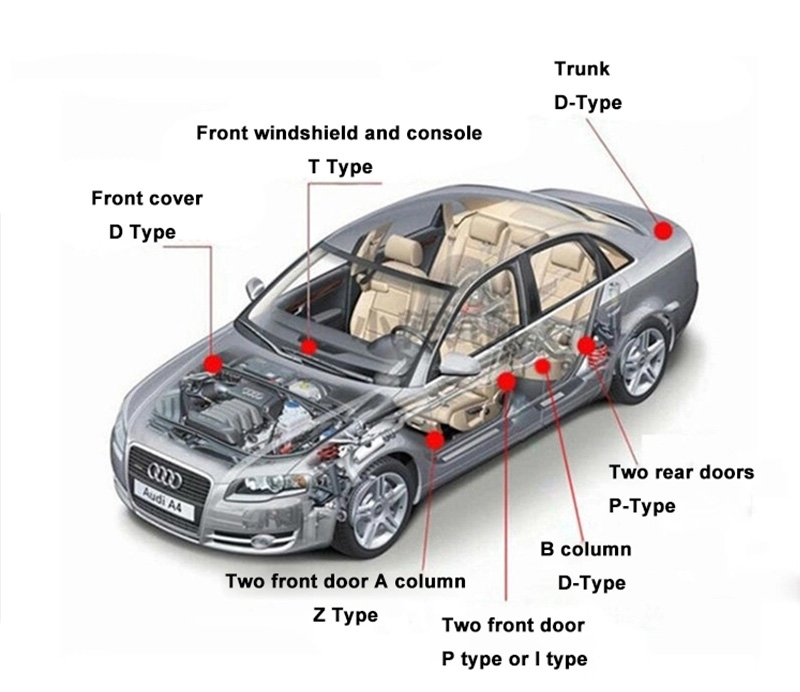

2. Molding and Extrusion The rubber is molded or extruded into specific shapes that match the design requirements of various vehicle models. This process allows for the creation of seals with intricate profiles that can effectively fit the contours of car doors.

3. Curing Curing is a critical process that involves heating the rubber material to facilitate cross-linking. This step enhances the material’s strength and elasticity, ensuring that the door seals will maintain their properties over time.

rubber door seals for cars factories

4. Quality Control After production, rubber seals undergo rigorous testing to ensure they meet industry standards for durability, water resistance, and temperature stability. Quality control measures are essential to identify any defects or inconsistencies in the products.

5. Customization Many manufacturers offer customization options to cater to specific automotive designs. This level of personalization ensures that the seals fit perfectly and perform optimally in diverse vehicle models.

Factors Influencing Quality

Several factors influence the quality of rubber door seals, including

- Material Composition The choice of raw materials directly impacts the performance of the seals. High-quality rubber compounds will exhibit better resilience and durability.

- Manufacturing Precision Advanced manufacturing technologies and processes ensure that seals are produced to exact specifications, enhancing fit and function.

- Environmental Considerations Manufacturers are increasingly focusing on producing eco-friendly rubber seals, utilizing sustainable materials and processes that reduce environmental impact.

- Continuous Innovation Ongoing research and development in materials science are leading to the creation of advanced rubber compositions that offer improved performance characteristics, such as enhanced wear resistance and temperature stability.

Conclusion

Rubber door seals are more than just a peripheral component of automotive design; they are integral to the overall functionality, safety, and comfort of vehicles. Understanding the manufacturing processes and factors that influence their quality is essential for automotive manufacturers aiming to enhance their products. As the industry continues to evolve, innovations in rubber seal technology will undoubtedly play a pivotal role in shaping the future of vehicle design and performance.

Share

-

The Best Lubricants for Aluminum Roller GuidesNewsJul.23,2025

-

Slitting Machine Applications in the Packaging IndustryNewsJul.23,2025

-

Rolling Roller Balancing Techniques for Smooth OperationNewsJul.23,2025

-

How To Optimize An EV Battery Assembly LineNewsJul.23,2025

-

Energy Efficiency in Modern Battery Formation EquipmentNewsJul.23,2025

-

Automation Trends in Pouch Cell Assembly EquipmentNewsJul.23,2025